Knowing the OEM/ODM process for custom airtight zippers is important for your manufacturing success. This knowledge helps improve product quality and makes your business run better. You can choose trustworthy suppliers and follow industry rules. This process also uses new technology, which makes products more reliable.

Things like the rise of online shopping and eco-friendly fashion rules raise the need for reliable zipper solutions. New methods in precision molding and anti-corrosion coatings make zippers last longer and speed up testing. These changes help you by reducing time to market and making sure your products meet high performance standards.

Key Takeaways

Knowing about OEM and ODM models helps you pick the best way to make your custom zippers.

Talking clearly with your manufacturer at the start can help you choose better materials and designs.

Understanding the minimum order quantity (MOQ) and lead times helps you plan and manage costs for your zipper production.

Using strategies like planning early and clear communication can really improve lead times for your projects.

ZIZIP‘s promise to quality assurance makes sure your custom zippers meet high performance standards through careful testing.

Understanding OEM and ODM: Two Collaboration Paradigms of ZIZIP

What is OEM?

OEM means Original Equipment Manufacturer. For airtight zippers, you work with a manufacturer to make zippers using your designs. This teamwork lets you keep control over the design and ideas. You can change everything about the zipper, like materials and how it works.

Here are some important parts of OEM teamwork:

Characteristic | Description |

|---|---|

Design Integration | Work with engineers to match zipper shape and fabric features during development. |

Material Selection | Use TPU and PU tapes that can be welded, stitched, or clamped for different options. |

Testing Standards | Check through ASTM D7757 leak testing to make sure zippers are airtight. |

Customization Options | Get CAD models, datasheets, and guides to improve designs. |

What is ODM?

ODM means Original Design Manufacturer. This model lets you use existing designs from a manufacturer. You gain from their designs while putting your brand on the product. This way is usually faster and cheaper than OEM, which is good for businesses that want to enter the market quickly.

Key Differences

Knowing the differences between OEM and ODM is important for your choices. Here’s a comparison:

Aspect | OEM | ODM |

|---|---|---|

Design Control & IP | 100% ownership of designs; can get patents. | Brand uses existing designs; limited or no IP filing. |

Development Cost | $5,000–$20,000+ | $0–$2,000 (branding only) |

Development Time | 10–16 weeks | 4–8 weeks |

MOQ | 500–1,000 units; tooling fees apply. | As low as 200 units; low setup costs. |

Customization | Unlimited materials, special hardware, unique features. | Limited to factory’s materials and hardware. |

Long-Term Brand Strategy | Creates unique product lines, builds brand loyalty. | Quick market testing before going with OEM. |

By knowing these models, you can make smart choices that fit your business goals and product needs.

Detailed Explanation of the Full Process for ZIZIP Custom Airtight Zipper Production

Initial Consultation

The process of making your custom airtight zippers starts with a meeting. In this meeting, you tell ZIZIP’s experts about your project ideas. They look at what you need and give you helpful advice. This teamwork helps you choose the best materials and designs for your project.

Design and Prototyping

After you decide on the details, ZIZIP goes to the design and prototyping stage. Here, engineers make detailed CAD models of your zipper. They think about things like length, color, and how the puller looks. Once they finish the designs, ZIZIP makes prototypes for you to check. This step lets you see how the zipper works and looks before moving on.

Sample Approval

After you look at the prototypes, the next step is to approve the samples. This important step makes sure the final product meets your needs. ZIZIP uses several rules to approve samples before making them in large amounts:

Criteria | Description |

|---|---|

Signed Samples | Act as the main reference for production teams, making expectations clear. |

Detailed Specification Sheets | Have exact measurements, material thickness, color codes, and other important details. |

Formal Approval Process | Needs key people to sign off on samples, adding responsibility to the process. |

Testing Parameters | Include strict tests like Salt Spray Test, Fatigue Testing, and Torque Resistance. |

To make sure everything is good, ZIZIP tests the samples, including:

48-72h Salt Spray Test

Fatigue Testing: 10,000 cycles

Torque Resistance: 15-25 N·cm

Temperature: -20°C to +80°C

These tests ensure that your custom zippers will work well in their intended uses.

Production Planning

Once you say yes to the samples, ZIZIP starts planning for production. This step includes scheduling and organizing resources for smooth mass production. ZIZIP’s production lines handle every part of making zippers. This method cuts down on delays and misunderstandings. Real-time tracking checks production progress, helping ZIZIP fix any problems quickly.

Mass Production

Finally, ZIZIP begins mass production. With everything ready, your custom zippers go into manufacturing. ZIZIP’s teamwork allows direct communication for feedback and approvals. This improves project management and makes sure your high-quality zippers meet all requirements. After production, ZIZIP carefully packs the zippers, ready to send to you.

By following this complete workflow, ZIZIP makes sure you get high-quality zippers made just for you. Their focus on innovation and quality makes them a reliable partner in the zipper manufacturing business.

MOQ and Lead Times for Custom Zippers

Understanding MOQ

Minimum Order Quantity (MOQ) is very important for making custom zippers. It means the least number of units a manufacturer wants you to order. Knowing about MOQ helps you plan your production and control costs. For custom airtight zippers, the usual MOQ is 500 units. This amount helps the manufacturer cover setup costs and keep production running smoothly.

Factors Influencing MOQ

Many things can affect the MOQ for your custom zipper orders. Here are the most common factors:

Factor | Description |

|---|---|

Choice of Material | The kind of raw material affects MOQ a lot. Regular materials may have lower MOQs, but special materials usually need higher amounts because of cost and sourcing needs. |

Production Complexity and Customization | More complicated designs and features raise the MOQ because they need more setup time and production details. |

Machinery and Setup Costs | Fixed costs for setting up production lines require higher MOQs to make sure production runs are profitable and efficient. |

By thinking about these factors, you can understand how to place your orders and talk with your zipper supplier better.

Typical Lead Times

Lead times are the time it takes from when you approve your samples to when your custom zippers are delivered. Here’s a typical breakdown of lead times for custom airtight zipper production:

Stage | Lead Time |

|---|---|

Sample Production | 7-10 days |

Mass Production (100-500) | 15-25 days |

Mass Production (1000+) | 25-40 days |

Material Sourcing | +5-10 days |

Air Freight | 7-10 days |

Sea Freight | 20-40 days |

Express Courier | 5-7 days |

Total Process | 30-60 days |

These lead times can change based on things like material availability and production schedules. Knowing these timelines helps you plan your projects better.

Strategies to Optimize Lead Times

To make sure your custom zippers arrive on time, think about using these strategies:

Early Planning: Start your project early. This helps with any unexpected delays in production or shipping.

Clear Communication: Keep in touch with your manufacturer. This helps solve any problems quickly and keeps the project moving.

Material Selection: Pick materials that are easy to find. This can cut down sourcing time and help meet your deadlines.

Flexible Shipping Options: Look at different shipping methods based on how urgent it is. Air freight is faster but costs more, while sea freight is slower but cheaper for big orders.

By using these strategies, you can improve lead times and make sure your high-quality zippers arrive when you need them.

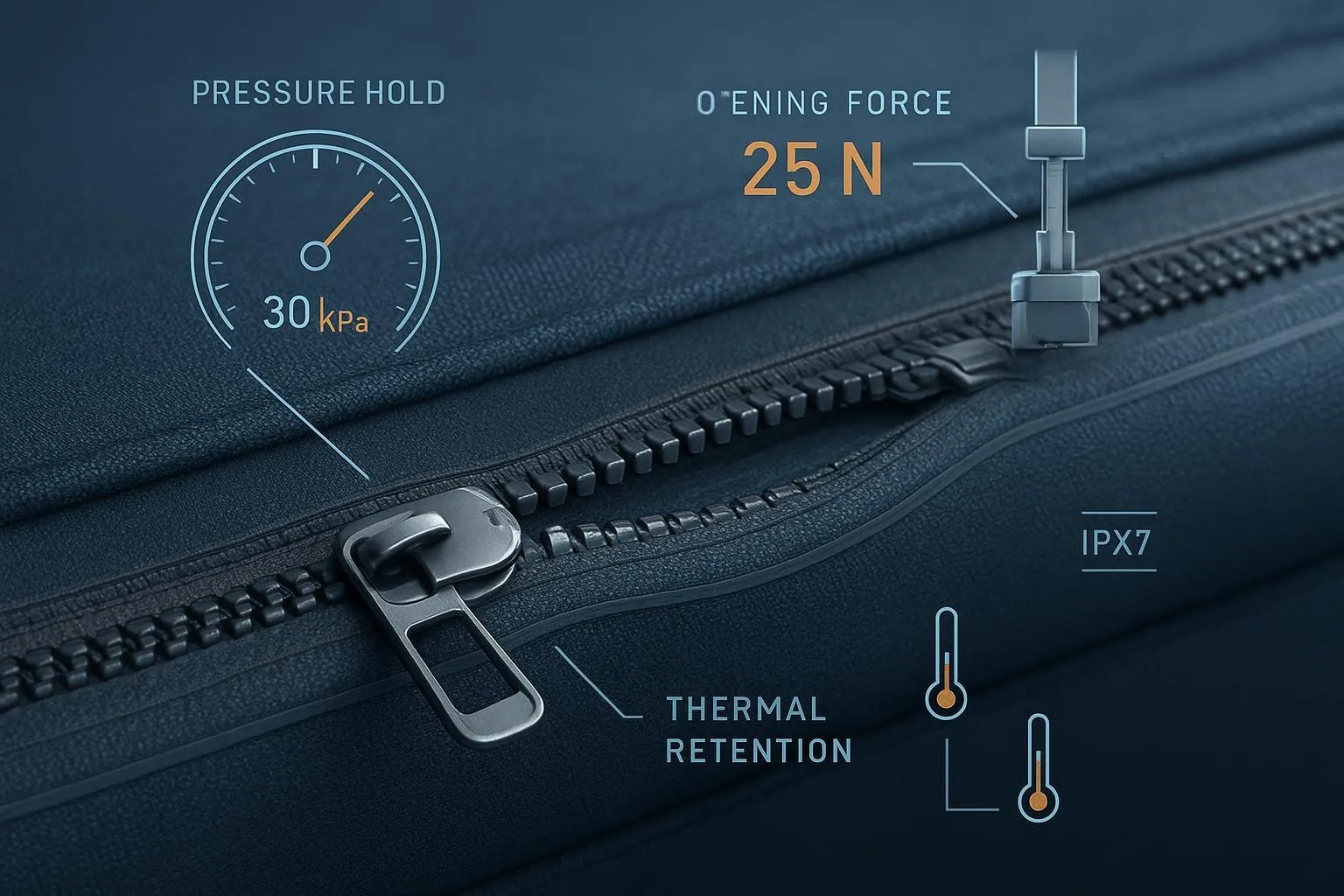

ZIZIP’s Core Commitment: Testing and Quality Assurance

ZIZIP focuses on strict testing and quality checks for its airtight zippers. You can be sure that every zipper goes through many tests to confirm it works well and is reliable. Here’s how ZIZIP does these important tests.

Types of Testing for Airtight Zippers

ZIZIP carries out several main tests to ensure the quality of its airtight zippers:

Tensile Strength Tests: These tests find out how much force is needed to pull the zipper apart. This makes sure the zipper can handle everyday use.

Durability Tests: Zippers are checked to see how they perform over time. This helps predict how well they will last in different situations.

Corrosion Tests: ZIZIP tests how well the zippers resist rust by exposing them to salt spray. This is very important for zippers used near water.

Immersion Tests: These tests check if the zipper can stay waterproof when submerged. They make sure the zippers can deal with tough conditions.

Besides these tests, ZIZIP also does special checks like:

Salt Spray Test: This puts the zipper in a 5% salt solution to mimic long-term rusting.

Waterproof Performance Tests: These tests confirm that zippers can handle being underwater, especially for marine and diving uses.

ZIZIP Full Process Quality Control System

ZIZIP has a complete quality control system during production. This system includes every inspection step, from when materials arrive to when the finished product is shipped. Here’s how it works:

Raw Material Inspection: ZIZIP checks all materials when they arrive to make sure they meet high quality standards.

In-Process Inspections: During making the zippers, ZIZIP regularly checks quality at each step. This helps find any problems early.

Final Product Testing: Before packing, every zipper is tested again to ensure it meets all requirements and performance standards.

This careful method makes sure you get high-quality zippers that work well in tough situations.

Compliance and Standards

ZIZIP follows important industry and international quality standards. This promise to comply ensures that every zipper meets safety and performance rules. Here are some key certifications ZIZIP has:

Certification | Importance |

|---|---|

OEKO-TEX® STANDARD 100 | Confirms that zippers are free from harmful substances, which is important for items that touch skin. |

REACH | Limits dangerous chemicals, ensuring high safety and environmental standards. |

ASTM F1670/F1671 | Tests how well the zipper stops synthetic blood and germs from getting through. |

By following these standards, ZIZIP guarantees that its products are safe and effective for many uses, including those in sensitive areas.

With ZIZIP’s focus on testing and quality assurance, you can trust that your custom airtight zippers will meet the highest performance and reliability standards.

The ZIZIP OEM/ODM process has many benefits for your custom airtight zipper projects. By using this clear method, you can get:

Cost Efficiency: Working together helps lower costs.

Quality Assurance: Skilled manufacturers make sure products are high quality.

Innovation Access: Get ready-to-use solutions that are already accepted.

Working with ZIZIP gives you long-term advantages. These include better sealing technology, flexible production, and a strong focus on teamwork. You can count on ZIZIP to help your project succeed. For specific projects, contact the ZIZIP team and start a smooth collaboration today!

FAQ

What is the minimum order quantity (MOQ) for custom zippers?

The minimum order quantity for custom zippers is usually 500 units. This number helps pay for setup costs and makes sure mass production runs smoothly.

How long does it take to produce custom zippers?

Production times can change. Making samples takes about 7-10 days. Mass production can take 15-40 days, based on the size and complexity of the order.

Can I customize the zippers for my luggage?

Yes, you can customize zippers for your luggage. ZIZIP has choices for length, color, and puller design to fit your needs.

What types of packaging do you offer for zippers?

ZIZIP has different packaging options, like plastic stand-up pouches. These pouches are great for keeping your zippers safe during shipping and storage.

How can I ensure the quality of my custom zippers?

ZIZIP does strict testing on all custom zippers. This includes tests for strength, durability, and rust resistance to make sure they perform well.