Sealing Excellence

Engineered for Extremes

Free Samples • Engineering Support • Fast Lead Time

for Waterproof & Airtight Zippers

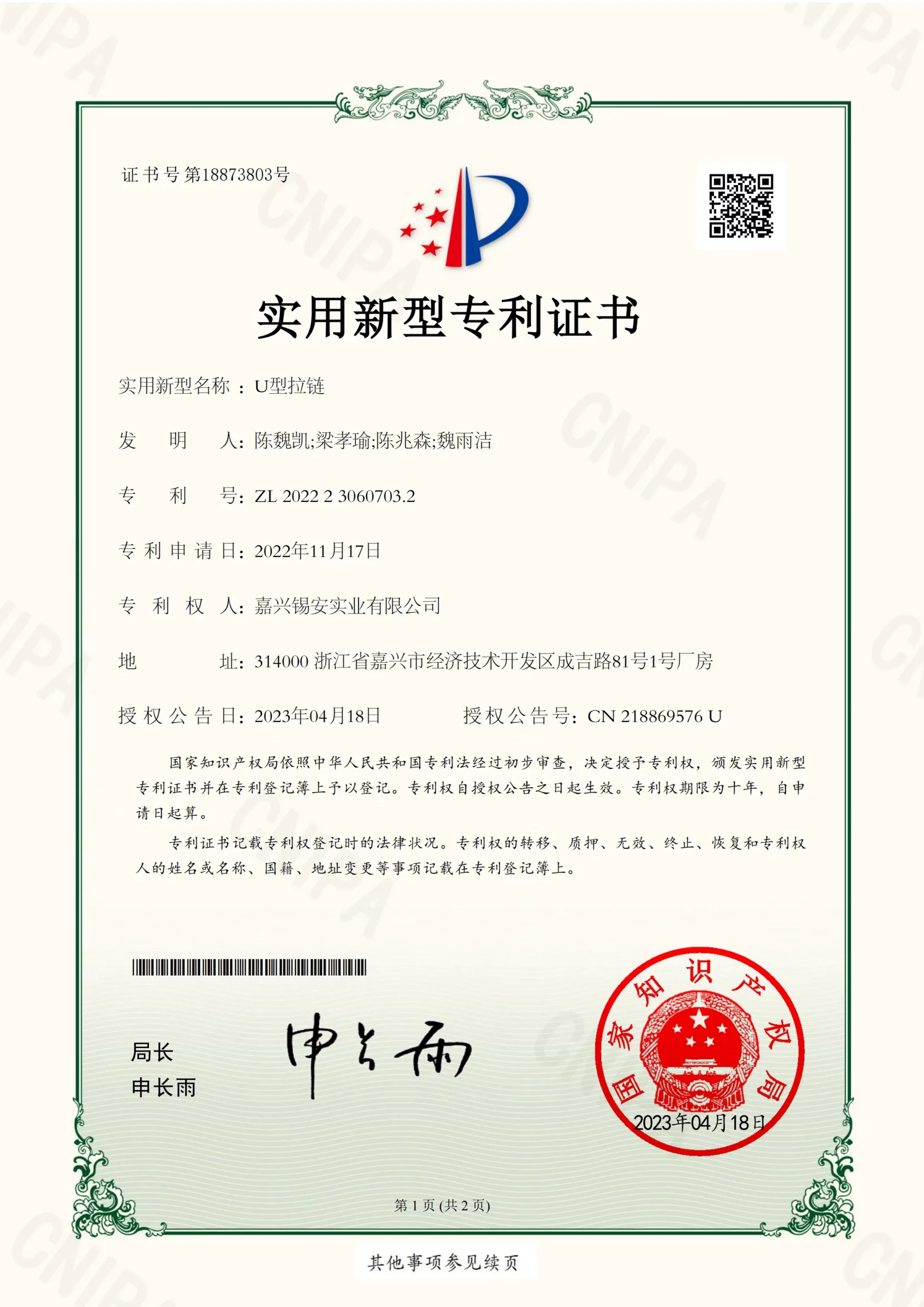

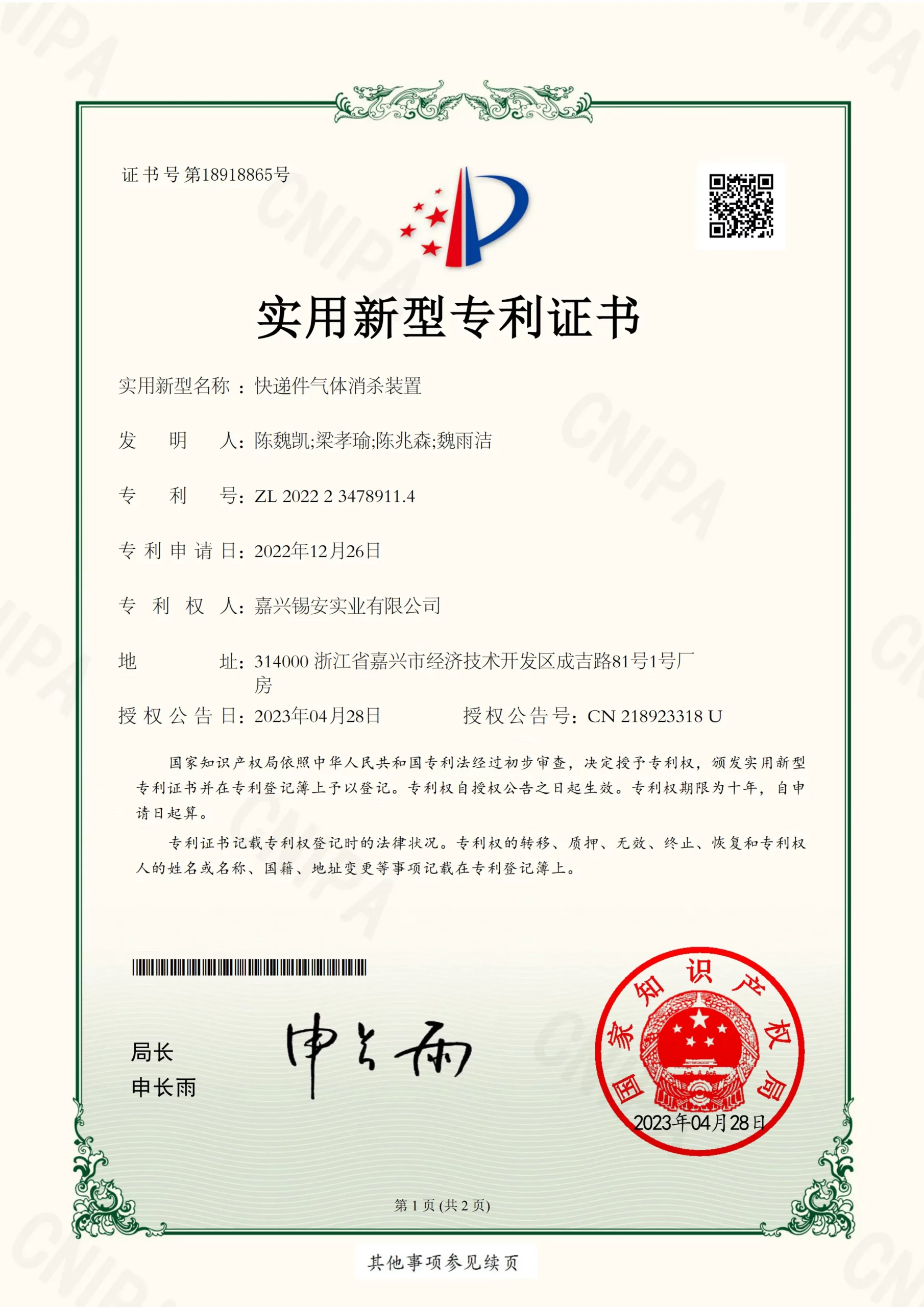

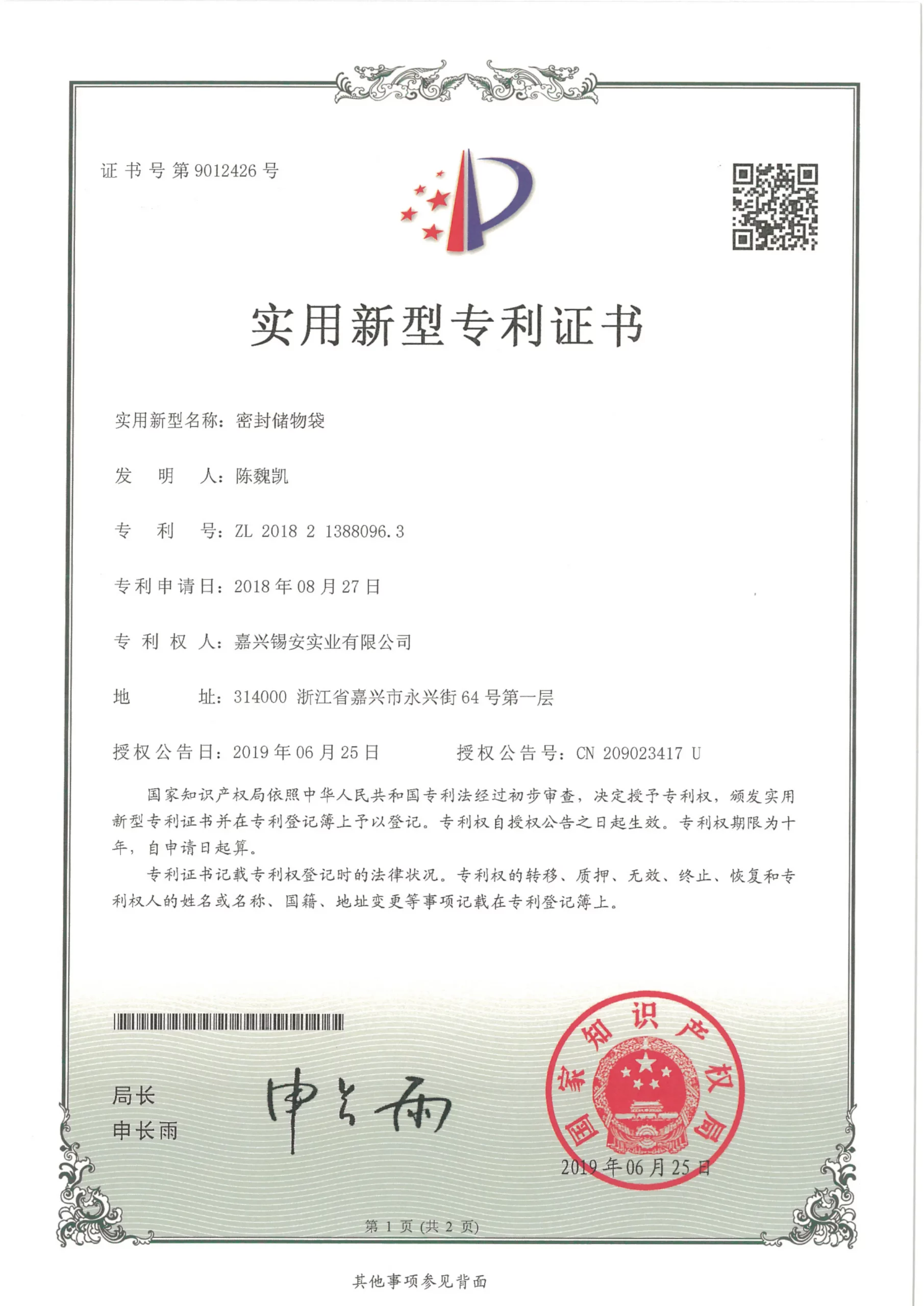

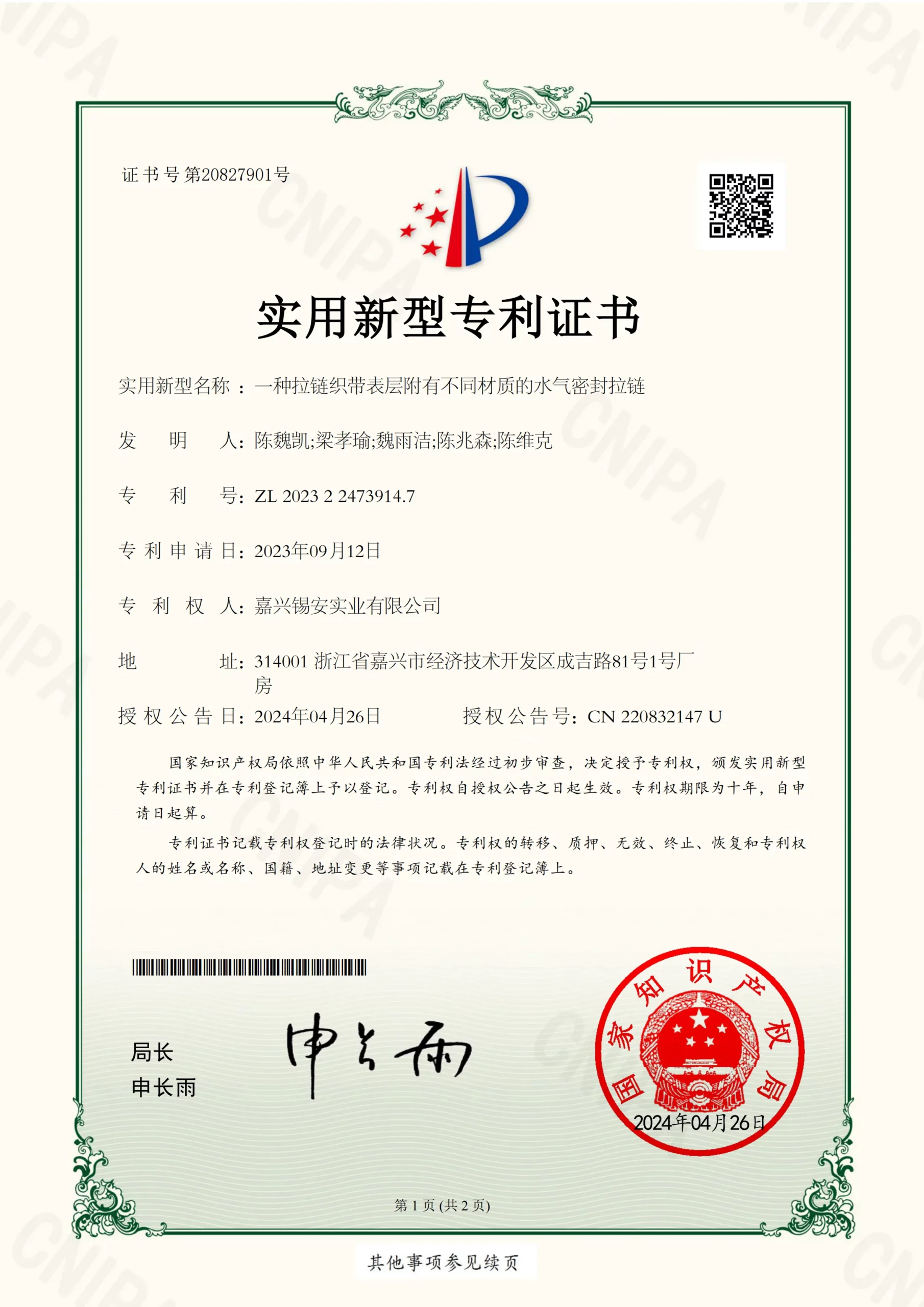

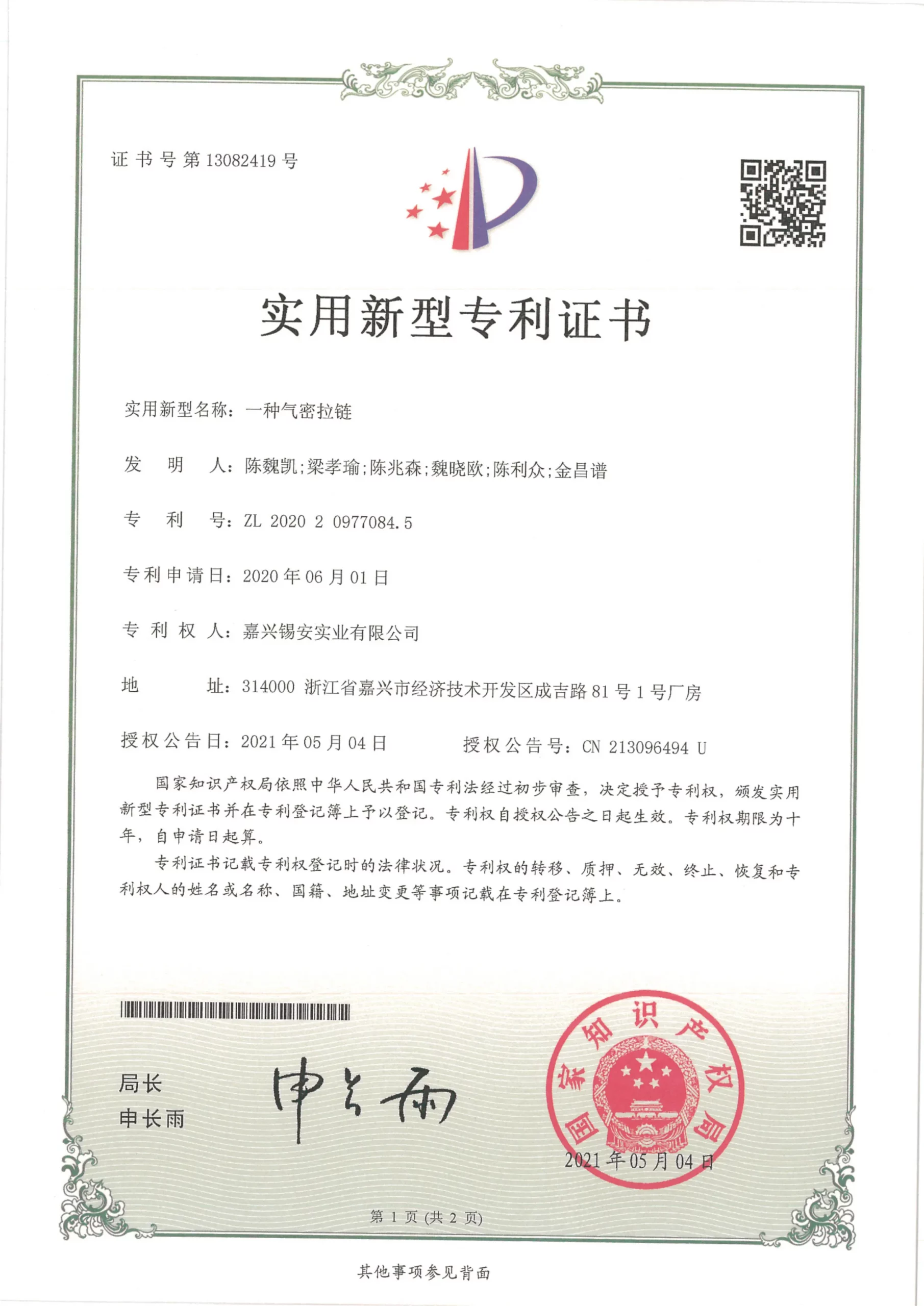

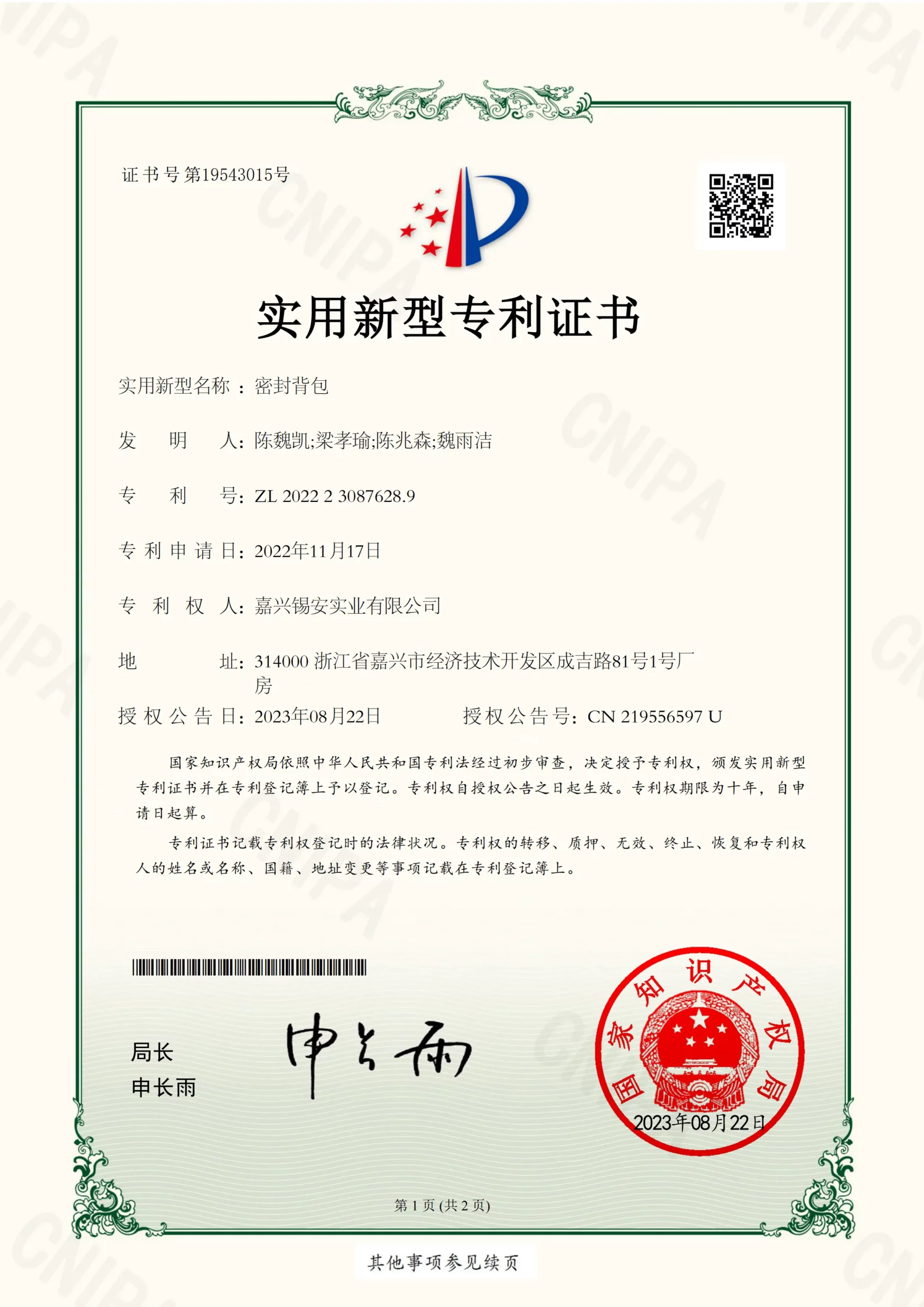

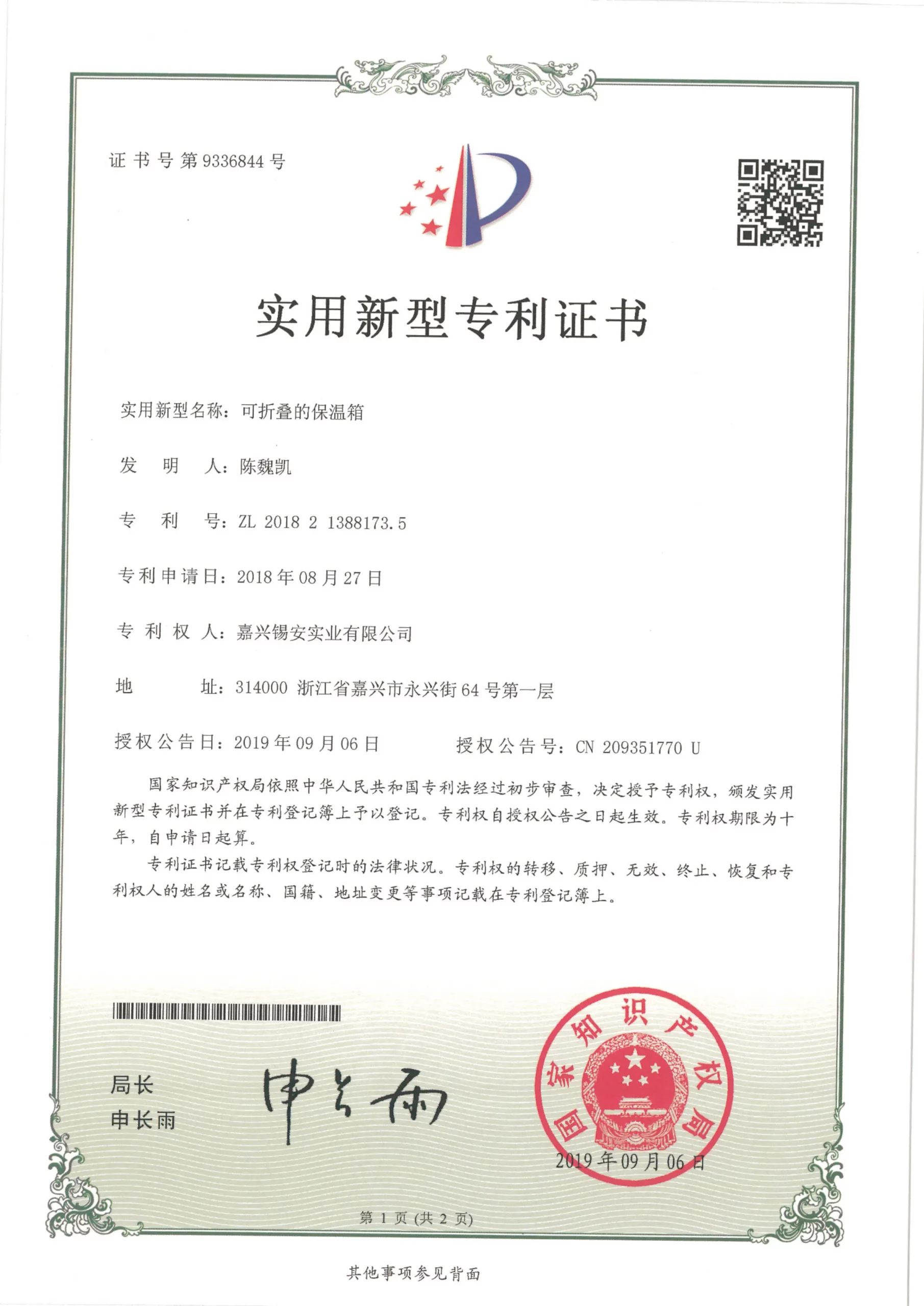

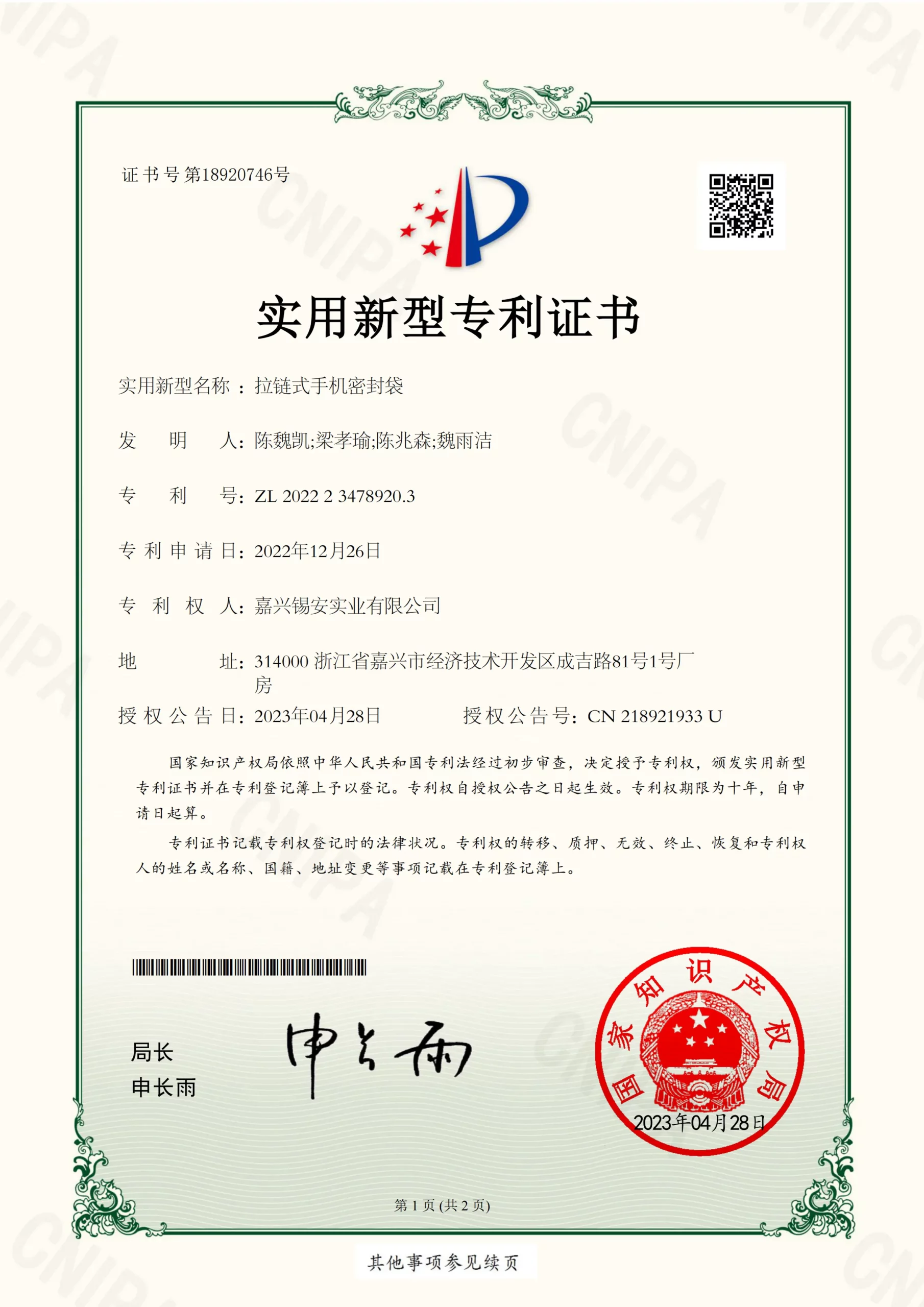

ZIZIP emerged from a relentless pursuit of innovation in hermetic sealing technology. With over 20 years of specialized expertise, we have established ourselves as a premier manufacturer of TPU-coated waterproof and airtight zippers engineered for extreme environments. Our capabilities are anchored by an independent R&D center that has secured 30+ utility patents in hermetic engineering, alongside fully automated production lines certified to ISO 9001:2015 standards. This technological infrastructure empowers us to deliver IPX5 to IPX8 graded sealing solutions, precisely engineered to fulfill diverse waterproofing demands — from daily-use to aerospace .

Product Categories

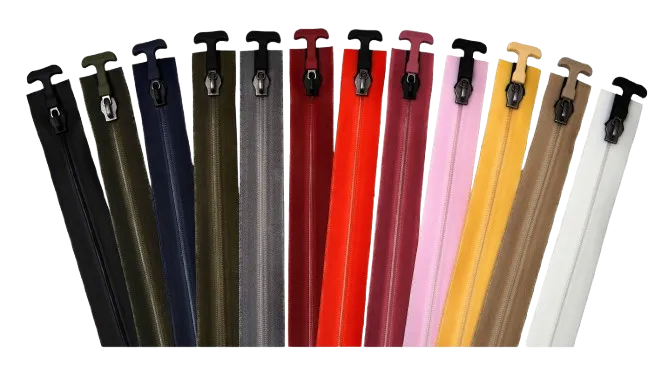

As a professional enterprise specializing in the R&D and production of waterproof and airtight zippers, we are proud to present our two main product lines – AeroSeal and AquaSeal – crafted to satisfy various demands.

AquaSeal™

for waterproofing

Aquaseal™ Waterproof Zippers leverage a dual-seal barrier formed by high-density polyester fabric fused with a precision-engineered TPU coating. This integration achieves IPX5-rated protection—resisting water ingress from heavy rain. Ideal for outdoor apparel and sports gear, it combines reliability with effortless operation and corrosion-resistant durability.

AeroSeal™

for airtighting

Aeroseal™ Airtight Zippers deploy patented TriSeal™ technology to create an impermeable barrier against liquids, gases, and microparticles. Certified to IPX7 (30-min submersion at 3m depth)and IPX8 (extended deep-water resistance), these zippers excel in critical environments like diving dry suits, hazardous material suits, and aerospace components.

Why Choose Us

Specialized Engineering & Innovation:

Advancing Sealing Science

With 20+ years of focused R&D in hermetic engineering, we pioneer sealing solutions through 30+ utility patents covering Dual-Track compression systems and cryogenic-flex TPU formulations. Our expertise in medical-grade airtight mechanisms enables solving extreme challenges—from deep-sea pressure isolation (5m/72hr IPX8) to aerospace cryogenic environments (-30°C). We set industry trends by transforming sealing technology from passive components to engineered safety systems.

Vertical Integration & Quality Control:

Precision-Driven Manufacturing

Our ISO 9001:2015-certified integrated facility controls 100% of production stages—from in-house TPU synthesis to final pressure validation—ensuring Precision Consistency. Proprietary automated lines guarantee:

•Supply chain resilience: 50% faster lead times vs. industry average (e.g., 72hr rush orders)

•Custom agility: 500 MOQ support for specialized configurations. Partners gain direct engineering access for real-time DFM optimization, eliminating communication barriers.

Performance Proven by Data:

Quantifiable Reliability

We validate superiority through third-party audited metrics exceeding global standards:

•Strength: 970N transverse tensile (38% > IPX5 compliance)

•Durability: 2,000+ reciprocating cycles (2× ASTM D2061)

•Environmental resilience: Zero delamination after -30°C/100°C thermal shock test reports (SGS/REACH) and material traceability

•Certificates: Download from our website or contact customer service.

OEM/ODM Service

Simply 4 steps to meet your product needs