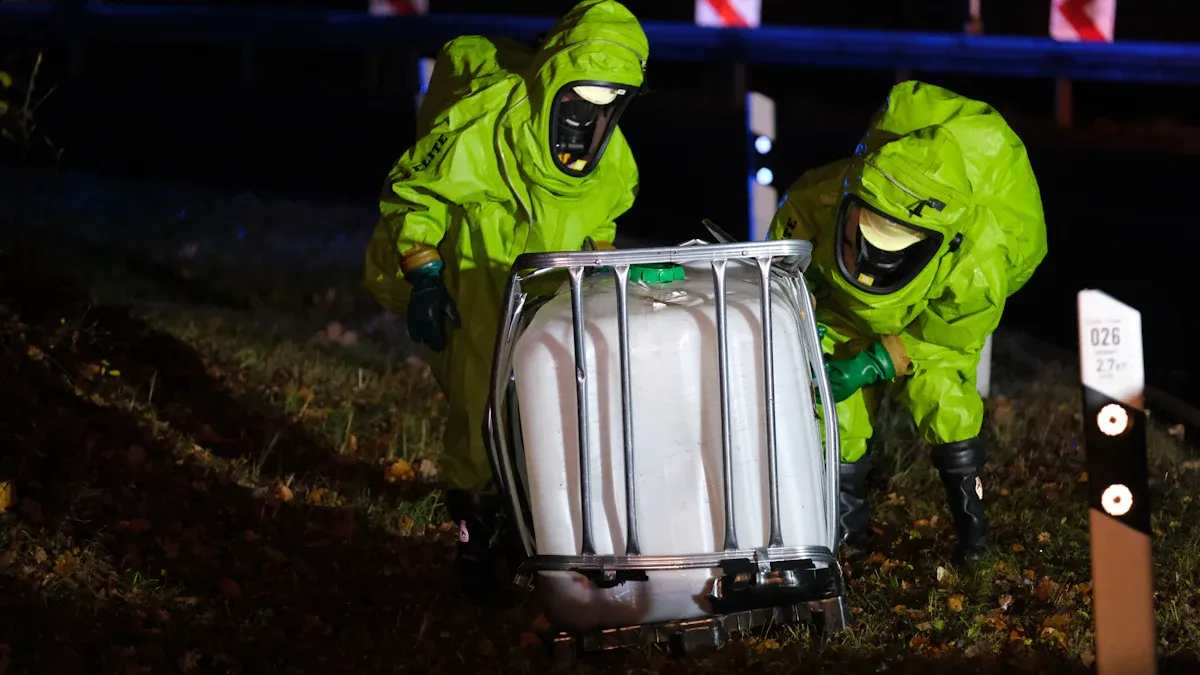

The reliability of zippers is paramount in HAZMAT (Hazardous Materials) and medical containment areas. You rely on them to create robust barriers against dangerous materials and pathogens. A single zipper failure can lead to severe consequences, including widespread contamination and safety breaches. Therefore, investing in high-quality sealing solutions is crucial for reducing risks and enhancing operational safety.

Key Takeaways

Zipper reliability is essential in HAZMAT and medical fields to prevent contamination and ensure personnel safety.

Choose specialized zippers with hermetic sealing capabilities to effectively block harmful chemicals, liquids, and pathogens.

Regular cleaning and lubrication are vital for maximizing zipper lifespan and preserving its functional integrity.

Understand the specific performance demands and regulatory requirements (e.g., medical vs. chemical resistance) for critical areas.

Verify certifications like OEKO-TEX® and REACH to ensure zippers meet strict safety and environmental standards.

The High Stakes: Understanding Zipper Failures

Zipper failures can happen in many ways. This is especially true in HAZMAT and medical areas. Knowing about these failures helps you see the risks and take steps to prevent them. Here are some common types of zipper failures you might see:

Common Failure Modes

Failure Mode | Description |

|---|---|

Stuck Zippers | Zippers that do not move easily, often because of dirt or being out of line. |

Broken Zipper Teeth | Teeth that are damaged or missing, which stops the zipper from closing. |

Slider Malfunction | Problems with the slider that stop it from working well with the teeth. |

Zippers Won’t Stay Closed | Zippers that open by themselves, risking the safety of medical gear. |

These failures can cause serious problems, especially where safety is very important.

Health and Safety Consequences

When zippers fail, the results can be bad. In medical isolation areas, zipper reliability is key for keeping safe. Here are some possible health and safety issues from zipper failures:

Health and Safety Consequences | Description |

|---|---|

Breaches in Sterility | Zipper failures can ruin the cleanliness of medical gear, which can cause contamination. |

Exposure to Biohazards | A broken zipper may put healthcare workers at risk from harmful germs. |

Increased Risk of Infection | Zipper problems in PPE can help spread infections, especially in places with strict rules. |

These issues show why it is important to keep zippers reliable in critical situations. By choosing high-quality zippers, you can lower the risks from zipper failures and improve safety in your work.

Specific Performance Demands and Root Causes

Zippers in HAZMAT and medical settings face unique challenges that dictate material choice and design. Understanding these demands is key to selection.

Challenge 1: Extreme Pressure and Immersion Integrity

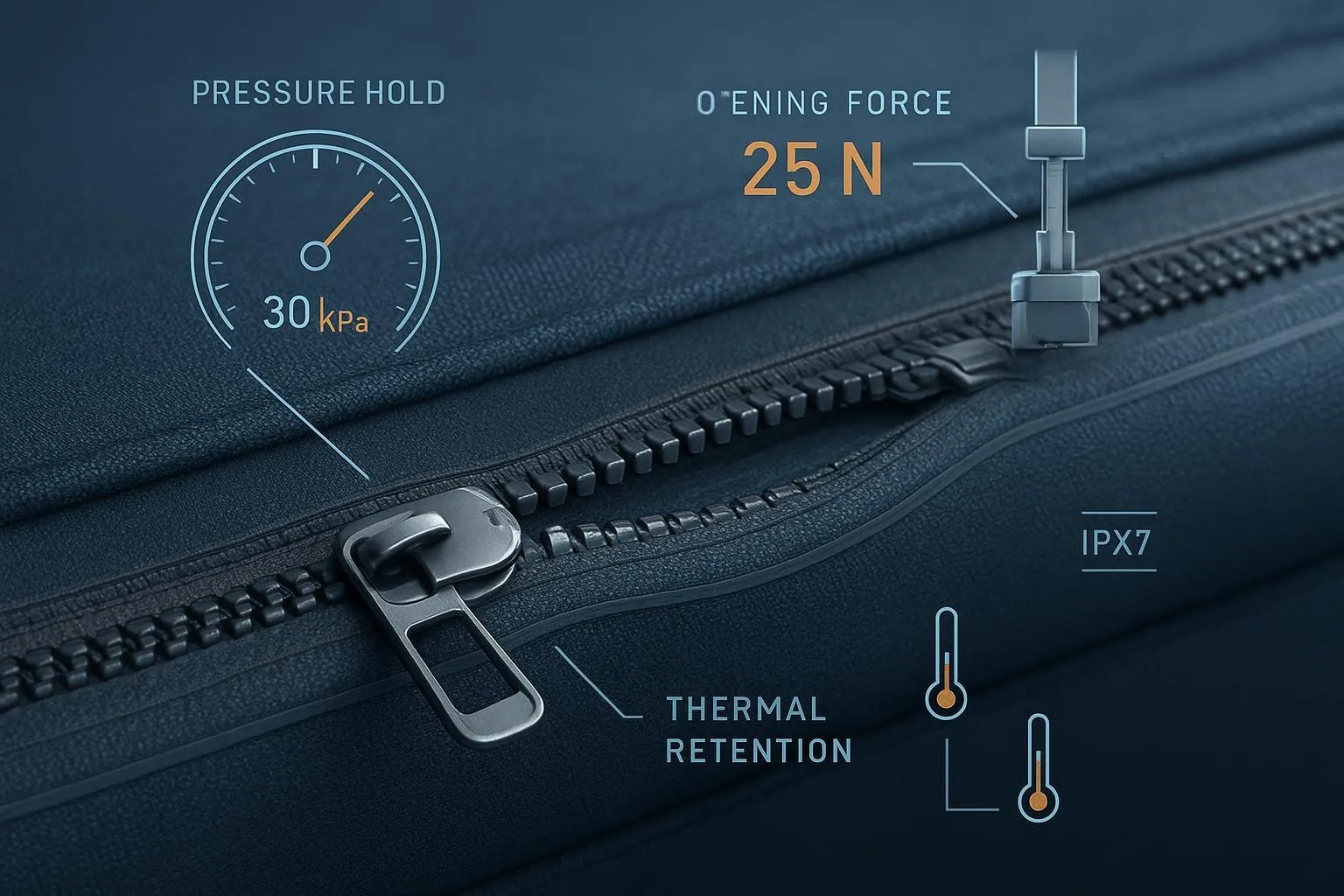

Professional zippers must withstand high stress without losing their sealing capability. For instance, airtight/watertight zippers used in diving suits or advanced HAZMAT gear must tolerate pressures exceeding 120 kPa (a standard measure for resistance to gas and liquid pressure).

Performance Aspect | Relevance in Critical Environments |

|---|---|

Ability to resist wear from frequent use, handling, and transport. | |

Environmental Resistance | Materials must resist degradation from disinfectants, oils, bleach, and temperature extremes. |

Heavy-duty Capacity | Designed for sustained use in protective suits, turnout gear, and specialized safety enclosures. |

Regular zippers often break down from rubbing, grease, bleach, and washing. So, you should pick industrial zippers with strong coatings and heavy-duty tapes to ensure they work well.

Challenge 2: Chemical and Pathogen Barrier

Key Isolation Properties and Advanced Technologies

The zipper must form an impermeable seal against harmful substances. This necessitates advanced sealing technology to prevent the leakage of liquids, gases, and microscopic contaminants.

Key features for strong zippers include:

Key Isolation Property | Function |

|---|---|

Hermetic Sealing | Provides a complete, airtight, and watertight barrier against fluids and airborne pathogens. |

Tri-Seal Technology | Employs a triple interlocking structure of the zipper teeth (or triple-rib structure) that creates three consecutive sealing points when closed, forming a redundant and continuous physical barrier against gas and liquid penetration. |

HF Weldable Tapes | The zipper tape material is specially formulated to support High-Frequency (HF) Welding to the suit fabric. This integration process creates a permanent, seamless bond, significantly reducing the risk associated with needle holes, thereby achieving a substantially improved barrier seal compared to traditional stitched assemblies. |

Material Biocompatibility | Ensures materials are safe for skin contact, which is vital for reusable medical components. |

Puncture Resistance | The zipper tape and sealing components must resist accidental physical damage. |

Root Cause Analysis of Barrier Failures

Zipper failures are rarely random events; they stem directly from specific environmental degradation common in critical environments. The most common issue, stuck or difficult operation, is typically caused by the accumulation of residues—specifically, disinfectant crystallization (such as concentrated bleach residue) or dried biological fluids (like blood or mucus) trapped within the fine grooves of the sealing lips, which severely increases friction.

Furthermore, structural failures like material degradation and broken teeth are accelerated by frequent exposure to UV radiation or potent oxidizing disinfectants (such as peracetic acid or high-concentration sodium hypochlorite). These harsh elements cause the embrittlement and accelerated aging of standard nylon or PVC components, often leading to tape shrinkage or component fracture. Preventing these failures requires investing in industrial-grade zippers with chemist-selected polymer coatings (like TPU) that are specifically formulated to resist common cleaning agents.

Challenge 3: Material Resilience and Compliance

To ensure compliance, zippers must meet different certification standards. Here are some key certifications to know:

Certification | Importance |

|---|---|

Chemical Safety ComplianceOEKO-TEX® STANDARD 100 | Certifies that zippers are free from harmful substances, crucial for direct skin contact items. |

REACH | Limits hazardous chemicals, ensuring high standards for safety and environmental care. |

Biological Barrier PerformanceASTM F1670/F1671 | Tests the zipper’s barrier effectiveness against penetration by synthetic blood and bloodborne pathogens. |

Integrated Prevention Strategies: Design and Maintenance

Maintaining zipper reliability requires a strategy that integrates careful material design with strict operational protocols.

Design and Selection Considerations

When sourcing zippers for critical applications, focus on the following technical features:

Material Choice: Prioritize durable materials like Thermoplastic Polyurethane (TPU) or Polyvinyl Chloride (PVC) coatings for their superior resistance to chemicals and temperature variations.

Sealing Technology: Select zippers featuring advanced sealing methods, such as Tri-Seal technology or high-frequency welding, to ensure a secure, consistent barrier against liquids and gases.

Customization: Tailor the zipper’s length, color, and puller design (e.g., large pullers for gloved hands) to specific application needs.

Maintenance Protocols

Regular care significantly extends the lifespan of professional-grade zippers and maintains seal integrity.

Clean Regularly: Remove dirt, debris, and abrasive particles that cause wear. Use mild soap and water for cleaning.

Lubricate Periodically: Only use manufacturer-approved, silicone-based lubricants that are compatible with the zipper’s specific coating (TPU/PVC). Apply evenly to the sealing lips and teeth, then run the slider back and forth to distribute. This preserves flexibility and the hermetic seal.

Handle with Care: Avoid excessive force when operating the zipper. Follow correct procedures, such as unzipping before cleaning or folding, to prevent stress damage.

By using these prevention strategies, you can improve zipper reliability and keep safety in HAZMAT and medical containment areas.

Validation: Testing Standards and Reliability Metrics

Reliability must be confirmed through rigorous testing standards and quantifiable metrics to ensure performance in critical containment scenarios.

Relevant Testing Standards

Beyond general material standards, international tests confirm barrier function:

ISO 17109: Specifies requirements and test methods for zippers intended for chemical and gas-tight protective clothing.

AATCC/ASTM Abrasion Tests: Used to evaluate the durability of the zipper tape and sealing coating after repeated friction and washing cycles.

Quantifiable Reliability Metrics

These metrics are essential for validating a zipper’s suitability for critical containment:

Metric | Description |

|---|---|

Seal Strength | Measures the force required to pull the closed zipper tracks apart, indicating the strength of the interlock. |

Repeated Open/Close Cycle Testing | Quantifies the number of cycles a zipper can sustain before a functional failure occurs (fatigue life). |

Leak Resistance (Air/Liquid) | Confirms the airtight or watertight capability of the seals using pressure tests (e.g., under water column pressure). |

Particle Ingress Testing | Tests whether microscopic particles (e.g., fine dust, viral particles) can pass through the zipper seal. |

Ease of Use and Alignment | Looks at how easily the zipper lines up and closes, often based on user feedback. |

Material Integrity | Checks for problems in the zipper material, ensuring good quality and performance. |

By focusing on these metrics, you can make sure that the zippers you choose meet the needed reliability standards for HAZMAT and medical uses. This validation process boosts your confidence in the safety and effectiveness of your containment solutions.

Selecting reliable zippers is a non-negotiable safety measure in HAZMAT and medical environments. By focusing on specialized hermetic design, chemist-selected materials, rigorous compliance testing, and professional maintenance, you can significantly enhance the safety and effectiveness of your containment solutions. To ensure your protective gear meets the highest standards, use the technical metrics and certification requirements outlined above to build a stringent procurement checklist.

FAQ

What types of zippers are best for HAZMAT and medical applications?

You should pick zippers that have hermetic sealing. ZIZIP’s AeroSeal zippers are a great choice. They protect against liquids, gases, and germs. This keeps you safe in important places.

How can I maintain zipper reliability?

To keep zippers working well, clean and lubricate them regularly. Use mild soap and water to clean them. Put lubricant on to help them move smoothly and avoid damage.

What certifications should I look for in zippers?

Look for certifications like OEKO-TEX® STANDARD 100 and REACH. These show that zippers do not have harmful substances and follow safety rules.

How do I know if a zipper is waterproof?

Check the zipper’s IPX rating. Zippers with IPX7 or IPX8 ratings are very waterproof. They can handle being in water without leaking.

Can I customize ZIZIP zippers for my specific needs?

Yes! ZIZIP lets you customize zippers for size, color, and puller design. You can change them to fit what you need.