Dual-Slider AquaSeal™ Waterproof Zipper

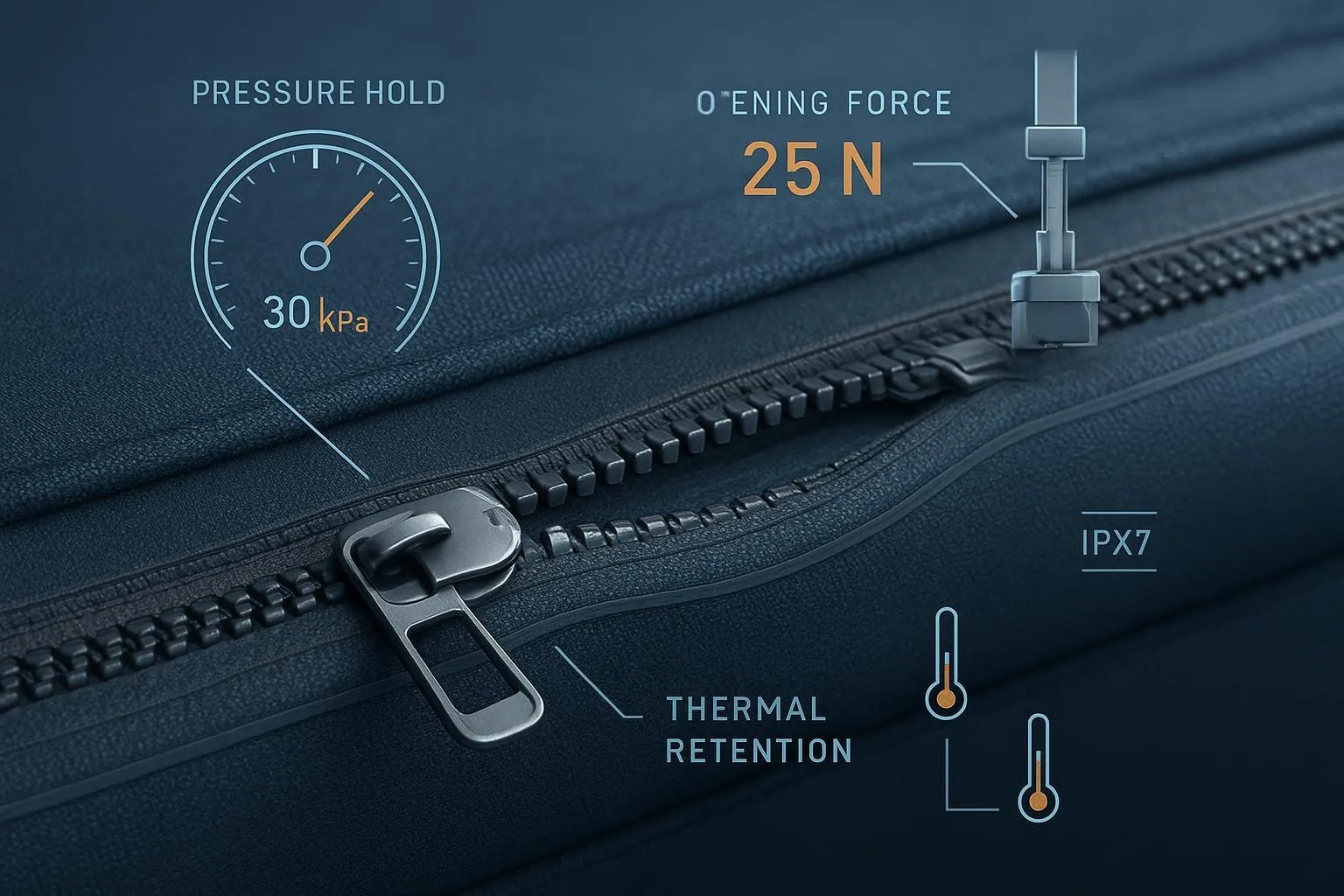

Flexible Two-Way Access with Proven IPX5 Water Resistance.

The Dual-Slider Aquaseal™ is designed for waterproof applications that demand flexible access.

By integrating two sliders onto our reliable IPX5-rated zipper chain, this configuration allows users to open large bags, tents, and covers from either end or from the middle. It’s the ideal solution for gear where convenient access is just as crucial as providing complete protection against rain and water spray

Key Feature

Flexible Two-Way Access

Two sliders allow for partial or full opening from either direction, simplifying access to large compartments.

Reliable IPX5 Water Resistance

The TPU-coated chain provides a strong seal against the elements, protecting contents from moisture.

Heavy-Duty Performance

Built to the same high standards of tensile strength and durability as our standard Aquaseal™ zippers.

Ideal for Gear & Covers

Perfect for the main compartments of duffel bags, boat covers, and tent doors where versatile access is needed.

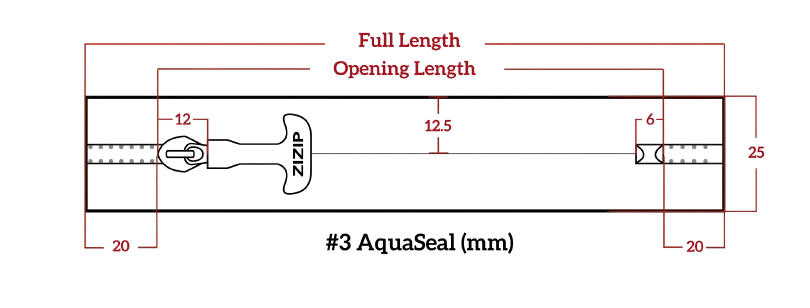

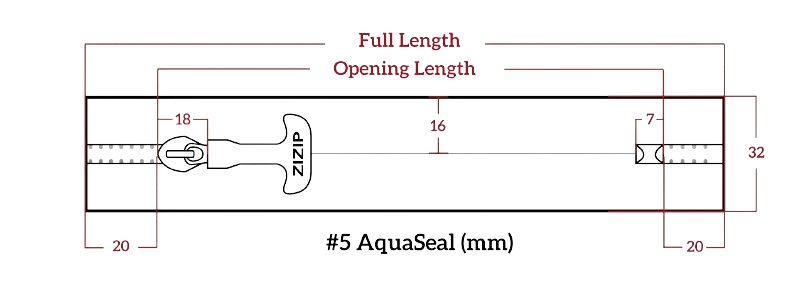

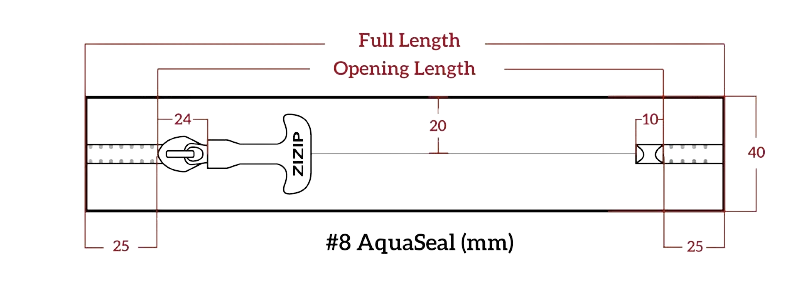

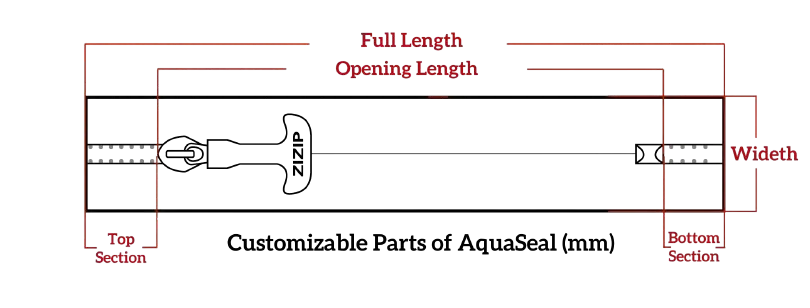

Find the Right AquaSeal™ Size

Technical Report

| Inspection Item | Test Result | Compliance Threshold |

| Transverse Tensile Strength | 970N | >700N |

| Slider Initial Pull Force | 30N | <40N |

| Smooth Sliding Performance | 25N | <30N |

| Abrasion Resistance | 150 continuous reciprocating cycles | 100 continuous reciprocating cycles |

| Tooth-to-Tape Peel Strength | 28-36N/27-38N/30-41N | Tooth Engagement Width 1.5cm, >=20N |

| Tape-to-Finishing Peel Strength | 24-33N/27-36N/25-33N | Tape Body Width 1.5cm, >15N |

| Reciprocating Test under Load | 1200 cycles | >1000 cycles |

| Waterproof Rating | IPX5 (SGS) | GB/T 4208-2017 IPX5 |

| Water Penetration Test | No water leakage observed during continuous 10-minue external surface spray test. | No water leakage observed during continuous 5-minute external surface spray test. |

| Slider Hardness | 115HV0.3 | Vickers-Hardness 0.3 Test (>80 HV0.3) |

| Slider Load Capacity | 170N | >100N |

| Slider Tensile Strength | 165N | >100N |

| Pull Tab Torque Resistance | 345N | >200N |

| Pull Tab Extraction Strength | 255N | >150N |

| Inspection Item | Test Result | Compliance Threshold |

| Transverse Tensile Strength | 970N | >700N |

| Slider Initial Pull Force | 30N | <40N |

| Smooth Sliding Performance | 25N | <30N |

| Abrasion Resistance | 150 continuous reciprocating cycles | 100 continuous reciprocating cycles |

| Tooth-to-Tape Peel Strength | 28-36N/27-38N/30-41N | Tooth Engagement Width 1.5cm, >=20N |

| Tape-to-Finishing Peel Strength | 24-33N/27-36N/25-33N | Tape Body Width 1.5cm, >15N |

| Reciprocating Test under Load | 1200 cycles | >1000 cycles |

| Waterproof Rating | IPX5 (SGS) | GB/T 4208-2017 IPX5 |

| Water Penetration Test | No water leakage observed during continuous 10-minue external surface spray test. | No water leakage observed during continuous 5-minute external surface spray test. |

| Slider Hardness | 115HV0.3 | Vickers-Hardness 0.3 Test (>80 HV0.3) |

| Slider Load Capacity | 170N | >100N |

| Slider Tensile Strength | 165N | >100N |

| Pull Tab Torque Resistance | 345N | >200N |

| Pull Tab Extraction Strength | 255N | >150N |

| Inspection Item | Test Result | Compliance Threshold |

| Transverse Tensile Strength | 970N | >700N |

| Slider Initial Pull Force | 30N | <40N |

| Smooth Sliding Performance | 25N | <30N |

| Abrasion Resistance | 150 continuous reciprocating cycles | 100 continuous reciprocating cycles |

| Tooth-to-Tape Peel Strength | 28-36N/27-38N/30-41N | Tooth Engagement Width 1.5cm, >=20N |

| Tape-to-Finishing Peel Strength | 24-33N/27-36N/25-33N | Tape Body Width 1.5cm, >15N |

| Reciprocating Test under Load | 1200 cycles | >1000 cycles |

| Waterproof Rating | IPX5 (SGS) | GB/T 4208-2017 IPX5 |

| Water Penetration Test | No water leakage observed during continuous 10-minue external surface spray test. | No water leakage observed during continuous 5-minute external surface spray test. |

| Slider Hardness | 115HV0.3 | Vickers-Hardness 0.3 Test (>80 HV0.3) |

| Slider Load Capacity | 170N | >100N |

| Slider Tensile Strength | 165N | >100N |

| Pull Tab Torque Resistance | 345N | >200N |

| Pull Tab Extraction Strength | 255N | >150N |

AeroSeal Airtight Zipper

AquaSeal Waterproof Zipper

Get A Free Quote

The Trusted Choice for Leading Outdoor and Performance Brands

Allows for easy packing and access to the main compartment without having to open the entire bag.

Provides convenient access points on large covers for boats, sails, or marine equipment.

Enables flexible ventilation options and easy entry/exit for large expedition tents.

Custom Engineered Sealing Solutions (OEM/ODM)

Our vertically integrated manufacturing process gives us complete control over production, allowing us to offer extensive customization for our partners. We work directly with your design and engineering teams to create waterproof and airtight zippers that meet your product’s exact technical and branding specifications.

Millimeter-Perfect Customization

Precision is paramount. We manufacture zippers to your exact length specifications, achieving millimeter-level accuracy. This dedication ensures seamless integration into your application, significantly minimizing material waste, and simplifies your overall assembly process.

Custom Colors for Brand Matching

Match your brand’s exact color palette. We provide custom color matching for both the zipper tape and the TPU coating based on the Pantone (PMS) color system, ensuring seamless integration with your product’s design.

Specialized Puller Designs with Your Logo

We offer a variety of industrial-grade zipper puller options tailored for different application scenarios, combining functionality, ergonomics, and visual appeal, with the option to customize brand logos upon request.

Custom Material & Coating

Engineered for your specific application. Our zippers are built with high-strength

Polyester fabric tape and coated with a high-performance TPU (Thermoplastic Polyurethane) layer. We work with you to ensure the material combination provides the optimal balance of flexibility, durability, and sealing performance.Consult our team of engineers and we will deliver the optimal solution tailored to your specific needs.

SUPPORT & FAQ

Minimum Order Quantity (MOQ)

Quality Certification And Testing

SGS waterproofing certification, ISO quality management system certification; Pre-delivery testing items: appearance (visual inspection), size (measuring tape), color (color difference meter), airtightness test (self-made testing equipment), smoothness (tensile tester), peeling severity, glue detachment test (repeated setting equipment), opening and closing test (manual inspection, presence or absence of jamming phenomenon), 90-degree arc pull (manual inspection, presence or absence of chain break phenomenon), packaging (visual inspection)

Technical Support

Material verification (customers can send materials for us to verify if they match the zipper)

Installation suggestions (for customers who have verified the materials, we can provide processing data such as pressure, temperature, time, etc.)

Usage instructions (daily maintenance and care guidelines for zippers)

Customization plans (providing sealing plan designs for special application scenarios such as aerospace equipment)

Payment Method And Terms

After-sales Service

The warranty period is 30 days after receiving the goods. Replacement is available (with additional repair strips provided).

Warranty coverage: It covers problems such as water leakage, air leakage, and broken zipper teeth caused by material defects or manufacturing processes.

Exclusions:

Human damage (such as cutting, violent pulling, chemical corrosion)

Failure to follow maintenance guidelines (such as causing the zipper to get stuck due to uncleaned sand)

Third-party repair or modification

Related News

If your packs work around water—kayaking re‑entries, canyon pools, river crossings, wet SAR logistics—short, unexpected immersions are not edge cases. […]

Designing a soft cooler or insulated delivery bag lives and dies by its closure. The wrong zipper can sabotage airtightness, […]

Heading out for casual kayaking or a weekend camp and just need fast, reliable guidance? This checklist prioritizes ease of […]

When you’re building dive bags or submersible gear cases, the real question isn’t “which zipper is the toughest?” It’s “which […]

When diving-suit zippers fail, they rarely fail politely. The most common field complaint after a few trips in salt water […]

When a garment promises waterproof protection, the zipper becomes a mission‑critical component. This checklist is built for R&D and quality […]