Validation is very important for making ZIZIP zippers. You need to check that each zipper meets high standards before going from sample to mass production. If validation is not enough, it can cause big problems, like product failure or unhappy customers. This is especially true for Airtight/Waterproof zippers, where being reliable is very important. By focusing on careful validation, you protect your product’s quality and performance. This helps it handle different environments well.

Key Takeaways

Validation is very important for ZIZIP zippers. It makes sure each zipper meets high standards. This helps stop product failures and unhappy customers.

Testing often during production helps find problems early. This means checking materials, design, and how well they work to keep quality high.

ZIZIP zippers go through tough water and airtight tests. This makes sure they work well in different weather and keep out moisture.

A complete quality check looks at every step of production. This includes checking materials, doing in-process checks, and testing the final product.

ZIZIP wants to do better than industry standards. By setting higher performance goals, ZIZIP builds customer trust and makes sure products are reliable.

Why verification is the core cornerstone of ZIZIP quality

From sample to mass production: how the reliability of ZIZIP runs through the entire process

Verification is very important for ZIZIP zippers. You need to make sure every zipper meets strict standards before selling it. This starts with careful testing during the sample phase. You check the materials, design, and how each zipper works. This helps you find problems early.

When you move to mass production, keeping this careful checking is key. Each group of zippers gets tested to make sure they work well. This includes checking if they are waterproof and airtight. This way, the zippers can handle different weather conditions. The trust in ZIZIP zippers comes from this strong focus on quality during the whole making process.

Risk Warning: What hidden dangers may unverified ZIZIP zippers bring

Zippers that are not verified can cause big risks. These risks can hurt your product’s name and safety. If you skip verification, you might face failures. This can lead to unhappy customers or even recalls. For example, there are cases where unverified zippers caused serious safety issues:

Product Type | Risk Description | Recall Details |

|---|---|---|

Children’s Necklaces | Risk of lead poisoning | Voluntary recall of about 6 million necklaces due to high lead content. |

Zipper Pulls | Risk of lead poisoning | Included in the same recall as the necklaces, posing similar safety concerns. |

Manufacturer | Stravina Operating Co. | Jewelry sold through various retail channels from March 2002 through September. |

Safety Concern | Lead toxicity | Lead can cause brain damage in children, prompting the recall by the Consumer Product Safety Commission. |

These examples show why testing and verification are so important. If you ignore these steps, you could put your customers at risk. This can lead to legal problems, money loss, and a bad brand image.

Quality Commitment: Verify how to safeguard every line of defense for the ZIZIP brand

At ZIZIP, you focus on quality by using a strong verification system. This system protects every part of making zippers, from raw materials to finished products. You do regular checks and tests to make sure each zipper is safe and works well.

Your focus on quality goes beyond just your own checks. ZIZIP also works with outside testing groups to confirm how well its zippers perform. This double-checking process makes sure your products meet and even beat industry standards. By doing this, you gain trust from your customers and strengthen the ZIZIP brand as a top choice for waterproof and airtight zippers.

Core testing system for ZIZIP sealed/waterproof zippers

Water tightness testing: How ZIZIP simulates extreme weather and usage scenarios

ZIZIP does tough water tightness tests. These tests check if zippers can handle hard conditions. They simulate heavy rain, splashes, and even being underwater. The goal is to make sure ZIZIP zippers stay waterproof in different situations.

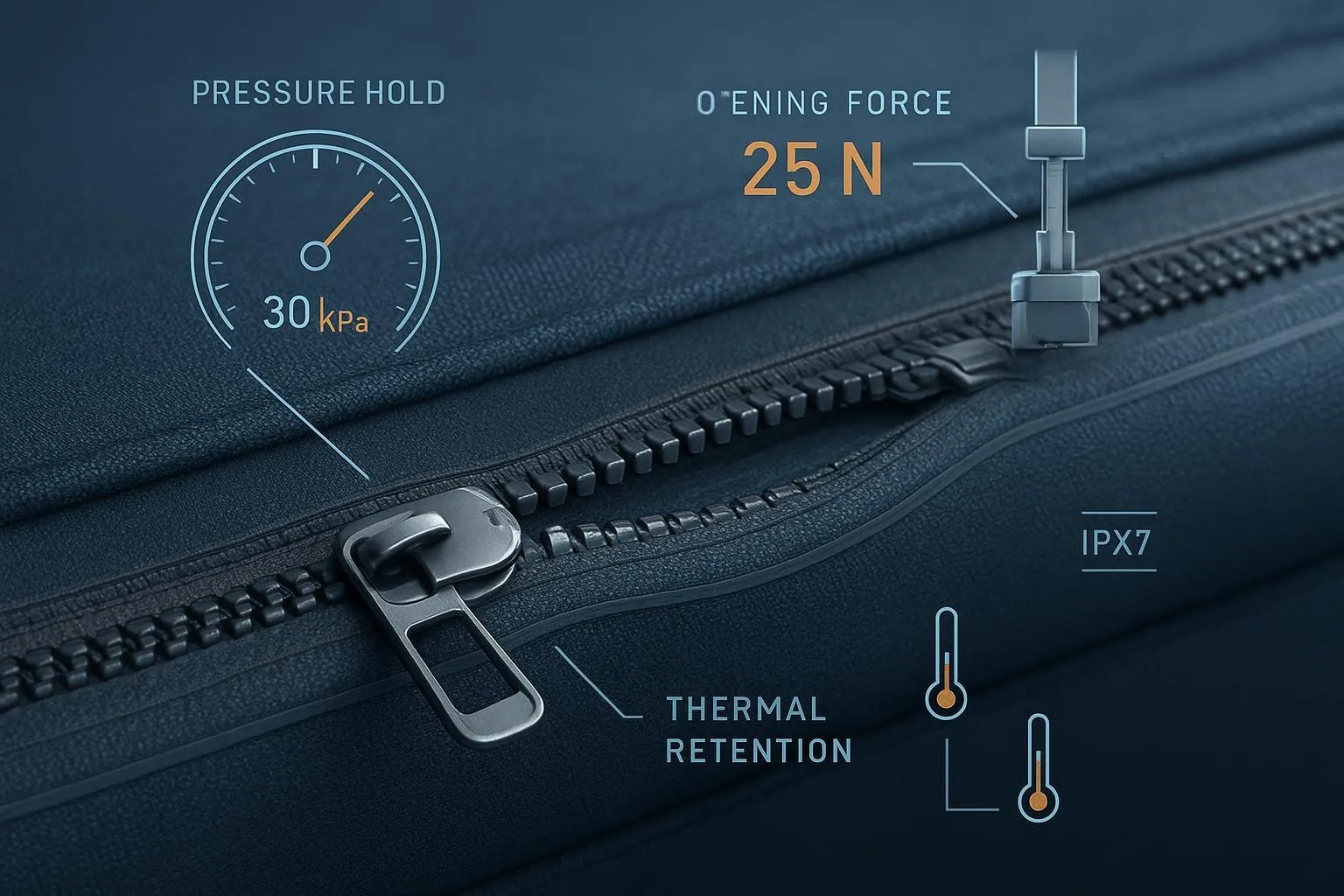

During these tests, ZIZIP uses strong water jets. This checks how well the zippers stop water from getting in. This method finds any weak spots in the zipper’s design or materials. ZIZIP zippers meet IPX ratings. These ratings show how much water they can resist. For example, AquaSeal zippers get an IPX5 rating. AeroSeal zippers can reach IPX7 and IPX8 ratings. These ratings mean you can trust the waterproofing of your products.

Airtightness testing: ZIZIP’s uncompromising pursuit of precision in sealing

Airtightness testing is very important for ZIZIP zippers. This is especially true for critical uses. You need to make sure these zippers seal tightly. This protects against moisture, gases, and tiny particles. ZIZIP solves common airtightness problems with careful design and good materials.

Here are some key things ZIZIP focuses on to avoid airtightness problems:

Mixing up waterproof and airtight standards can lead to wrong zipper choices.

Problems in the meshing and coating of zipper teeth can let moisture in.

Bad slider design can cause leaks and hurt sealing.

Wrong installation can lead to failures, like unsealed sewing pinholes.

To fix these issues, ZIZIP uses several methods:

Precision engineering makes sure zipper teeth fit perfectly.

High-quality materials, like double-layer TPU coating, stop moisture from getting in.

The slider design has a strong self-locking feature to avoid gaps.

Good installation techniques seal sewing pinholes and make sure zippers last.

Durability testing: Performance stability verification of ZIZIP zippers throughout their lifecycle

Durability testing checks if ZIZIP zippers work well over time. You can expect these zippers to go through tough wear tests. They simulate daily use with many opening and closing cycles. This testing makes sure the zippers stay reliable throughout their life.

ZIZIP follows strict rules for testing durability. Here are some key parts of their durability testing:

Zippers go through wear tests with many opening and closing cycles.

Testing simulates heavy daily use with cycles from 500 to over 1,500 times.

Fatigue testing means opening and closing the zipper thousands of times.

Lateral strength tests check if zipper teeth can handle pressure.

ZIZIP zippers meet the ASTM D2061 standard. This covers tests for strength, including chain strength and slider pull-off resistance. This thorough approach to durability testing ensures you get zippers that can handle tough uses.

ZIZIP Quality Assurance: More Than Just Basic Control

ZIZIP Full Process Inspection Protocol: Check every step from raw materials to finished products

ZIZIP has a complete quality assurance process. This makes sure every zipper meets high standards. You check every step in the production chain, starting with raw materials and ending with the finished product. This process includes:

Material Inspection: You look at all raw materials for quality before they start production.

In-Process Checks: While making zippers, you do regular checks to find any problems early.

Final Product Testing: After making them, each zipper goes through tough testing to make sure it works well.

This full process inspection protocol makes sure ZIZIP zippers give reliable waterproof and airtight protection.

ZIZIP Performance Benchmark: Why We Aim Higher than Industry Standards

ZIZIP sets performance goals that are better than current industry standards for airtight and waterproof zippers. This promise to be the best ensures that you get products that work really well. Here are some key benchmarks:

Benchmark | ZIZIP Performance | Industry Standard |

|---|---|---|

Transverse Tensile Strength | 1205N | 900N |

Durability (Reciprocating Cycles) | 2000 cycles | 1000 cycles |

Temperature Resistance | -30°C for 24 hours, 100°C for 10 minutes | N/A |

Corrosion Resistance | 48-hour salt spray test | N/A |

These benchmarks show ZIZIP’s commitment to giving zippers that have better sealing and water resistance.

Meet and exceed industry standards: dual certification of ZIZIP and third-party testing

ZIZIP goes beyond just internal quality checks. It gets dual certifications from well-known industry groups. You also use third-party testing to confirm how well your zippers work. This dual approach makes sure ZIZIP products not only meet but also exceed industry standards. By doing this, you build customer trust and satisfaction. The tough testing shows that both AquaSeal and AeroSeal zippers provide the protection you need in tough situations.

From Sample to Mass Production: ZIZIP’s Path to Large Scale Quality Control

ZIZIP Process Parameter Transfer Specification in Large Scale Production

When you move from making samples to mass production, you must keep a close eye on process parameters. ZIZIP uses a clear method to make sure everything stays the same. Parameters are taken from a normal distribution around set points. This helps create realistic tests and shows how changes affect the final product.

Evidence Description | Key Points |

|---|---|

Simulation of process parameters | Parameters are taken from a normal distribution around set points. |

Impact of variation on product | Changes in parameters are tracked to see how they affect the final product. |

Establishing control strategies | Development data helps focus on important changes and uncertainties. |

Updating Integrated Process Model (IPM) | The IPM predicts when things might go wrong and suggests fixes. |

Experimental screening range | Parameters are split into grids for careful exploration. |

How ZIZIP responds to typical challenges and variation control in mass production

ZIZIP faces problems during mass production, like keeping quality and handling changes. To solve these issues, ZIZIP uses statistical process control (SPC) methods. These methods help you watch production closely and make sure every zipper meets quality standards.

SPC Method | Purpose |

|---|---|

X-bar Chart | Watches process mean stability to spot problems. |

R-chart | Tracks changes in process spread. |

P-chart | Checks the number of defective items. |

Continuous Monitoring and Optimization: ZIZIP’s Method for Ensuring Batch Consistency

ZIZIP uses data analysis to improve production processes. This helps you keep high-quality standards and work more efficiently. Here are some key strategies:

Predictive Maintenance: Sensor data and machine learning find possible equipment failures before they happen.

Quality Control: Real-time data and AI spot defects early in the production process.

Supply Chain Optimization: Looking at sales trends helps predict demand and manage inventory better.

Production Efficiency: Finding bottlenecks leads to more output and smoother operations.

By using these methods, ZIZIP makes sure that every batch of zippers keeps the same quality and performance. This promise to excellence strengthens your brand’s reputation for reliable waterproof and airtight zippers.

Summary: ZIZIP Verification System – The Ultimate Guarantee of Reliability

Reiterating the significance of ZIZIP comprehensive verification for customer trust and brand value

You can trust ZIZIP zippers because of our strong verification system. This system makes sure every zipper meets high quality and performance standards. By focusing on careful testing, you protect your investment and improve your brand’s image. Customers like knowing that ZIZIP zippers offer reliable sealing and protection in different conditions. This trust is very important for building long-lasting relationships with your clients.

Only through system verification can we achieve outstanding performance for every ZIZIP zipper

ZIZIP zippers go through a lot of testing to make sure they get the highest IPX ratings. These ratings show how well our zippers keep out water and air. For example, AquaSeal zippers get an IPX5 rating, while AeroSeal zippers can reach IPX7 and IPX8 ratings. This level of performance ensures that our zippers give great protection against moisture and other environmental factors.

To keep quality control during mass production, ZIZIP uses several strategies:

Regular Inspections: You check at every step of production to find any problems early.

Statistical Process Control: This method helps watch production processes and keep quality steady.

Continuous Improvement: You look at data to make production methods better and improve performance.

By using these strategies, ZIZIP makes sure that every zipper performs well and meets customer needs. Your focus on quality and verification makes ZIZIP stand out in the market, making it the top choice for waterproof and airtight zippers.

FAQ

What makes ZIZIP zippers good for travel?

ZIZIP zippers are waterproof and airtight. This makes them great for travel bags. You can trust them to keep your things safe from water and dust. This helps you have a worry-free trip.

How do I take care of my ZIZIP zippers?

To take care of ZIZIP zippers, clean them often with mild soap and water. Don’t use strong chemicals. Make sure they are dry before you store your travel bags to avoid damage.

Can ZIZIP zippers be changed for special needs?

Yes, ZIZIP zippers can be changed. You can pick sizes, colors, and styles to match your travel bags perfectly. This lets you create the best fit for your products.

Are ZIZIP zippers tested for tough conditions?

Yes! ZIZIP zippers go through tough tests for waterproofing and airtightness. They are made to work well in hard conditions, making them dependable for all your travel adventures.

Where can I buy ZIZIP zippers?

You can buy ZIZIP zippers directly from our website or from approved sellers. Check out our products to find the best zippers for your travel needs.