AquaSeal™ Waterproof Zippers:

Your First Line of Defense Against The Elenents

Zero penetration

Innovating Waterproofness

Engineered with high-density polyester fabric coated in thermoplastic polyurethane (TPU), the AquaSeal zipper forms a continuous compressible sealing layer through mutual compression of TPU coatings. Certified IPX5 waterproof (resisting water jets up to 100 L/min at 30 kPa), it delivers reliable protection for demanding outdoor and aquatic applications.

Extreme Temperature Resistance:

Maintains full operational functionality after 24-hour exposure at -30°C and after a 5-minute immersion in 100°C boiling water.

Corrosion Resistance:

Successfully passes a 48-hour salt spray corrosion test.Compatible with marine environments

Waterproof Rating And High Durability:

Certified to achieve an IPX5 waterproof rating.Resists heavy rain and pressurized water spray

Proven to withstand 1200 reciprocating cycles under load.Suitable for high-frequency use (e.g., backpacks, tents)

Smooth Operation Operational Smoothness:

Engineered for ease of use with an initial pull force of 30N and smooth sliding performance of 25N.Optimized slider mechanics reduce user fatigue

Custom Engineered Sealing Solutions (OEM/ODM)

Our vertically integrated manufacturing process grants us complete comprehensive oversight across every production stage, empowers us to offer unparalleled customization capabilities for our partners. We collaborate directly with your design and engineering teams to create waterproof and airtight zippers that meet your product’s exact technical specifications and brand vision.

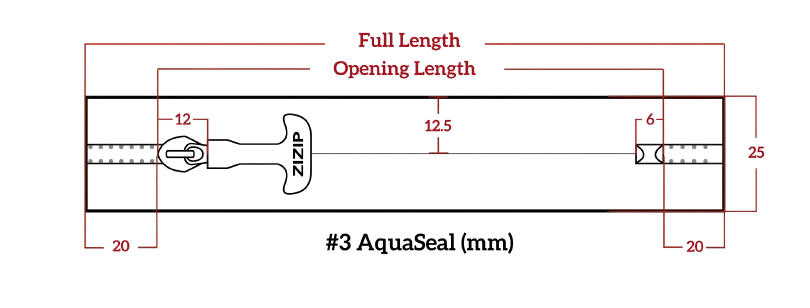

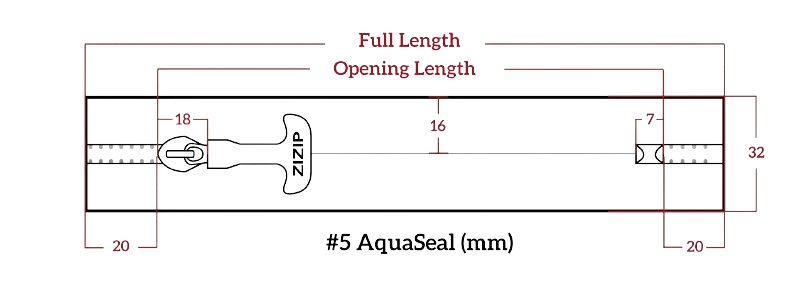

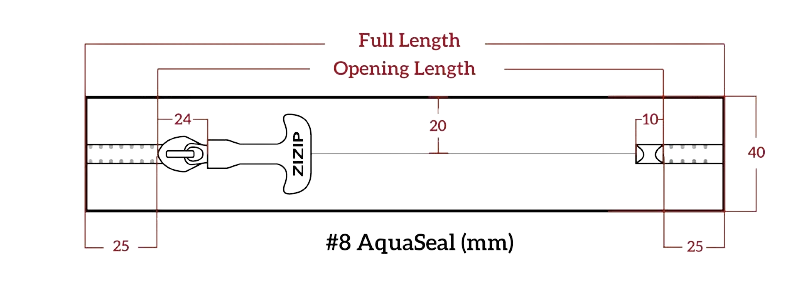

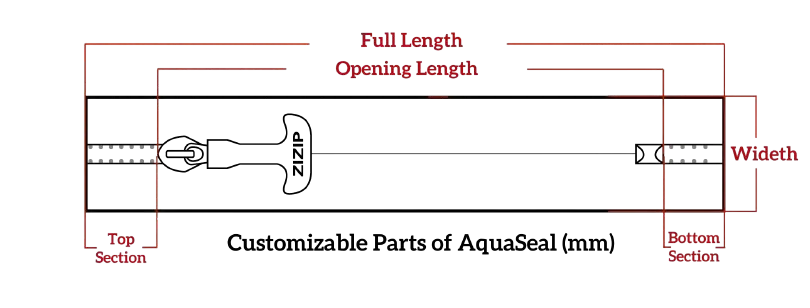

Find the Right AquaSeal™ Size

Custom Colors for Brand Matching

Match your brand’s exact color palette. We provide custom color matching for both the zipper tape and the TPU coating based on the Pantone (PMS) color system, ensuring seamless integration with your product’s design.

Custom Material & Coating

Specialized Puller Designs with Your Logo

We offer a variety of industrial-grade zipper puller options tailored for different application scenarios, combining functionality, ergonomics, and visual appeal, with the option to customize brand logos upon request.

Long T-Shaped Zipper Puller

Short T-Shaped Zipper Puller

Oval Ring Puller

Round Hook Puller

Cord Zipper Puller

Injection T-Puller

Select Your AquaSeal™ Configuration

Every design has unique requirements. The Aquaseal™ series is available in multiple configurations to provide the perfect function for your apparel, bags, or protective covers.

Engineered for Precision, Tailored to Your Application

Our zippers are meticulously constructed from high-strength polyester fabric tape, expertly coated with a high-performance Thermoplastic Polyurethane (TPU) layer. We specialize in flexibly customizing every aspect to align with your product’s unique demands. Collaborating closely with you, we ensure the material combination delivers the optimal balance of flexibility, durability, and sealing efficacy. Consult our dedicated team of engineers, and we will craft and deliver a bespoke solution precisely tailored to your specific project imperatives.

ZIZIP in Action: Proven Performance

Discover how ZIZIP’s advanced sealing solutions deliver unparalleled performance across diverse industries. Explore our case studies to see our commitment to innovation and reliability in practice.

Waterproof Coveralls

Diving Suits

Water Walking Ball

Waterproof Duffel Bag

Fishing Tackle Bag

Waterproof Shoes and Boots

Why Choose Us

20+ Years of Specialization

With over two decades of focused innovation in hermetic sealing solutions, we have developed proprietary TPU-coating technologies that redefine durability and reliability in extreme environments. Our specialization is not just in manufacturing, but in solving critical sealing challenges for medical, and aerospace applications

Innovation & R&D

As a National-Certified High-tech enterprise, our R&D leverages 30+ utility patents in hermetic sealing, including:

– Dual-Track IPX8 Sealing: Patented chain-tooth structure enabling 72-hour leak-proof submersion (10m depth)

– Cryogenic Flexibility Tech: Maintains operational smoothness at -30°C (exceeding ASTM D2061 standards)

– 7.2% annual R&D investment drives continuous innovation in high-pressure sealing failure mitigation

Certified Quality

Certified to ISO 9001:2015 & GB/T 19001-2016, we enforce protocols exceeding standards:

– Material traceability:Medical-grade TPU batch tracking (SGS MSDS-certified)

– Brutal testing: Every batch undergoes -30°C freeze → 100°C boil → 48hr salt-spray torture tests

Integrated Solutions Provider

From prototyping to mass production, we deliver:

– Co-development: we provide seal simulation reports to reduce client trial costs

– Custom agility: Support wideth/length/color combinations

– Global tech support: 24/5 engineer access with 72-hour failure diagnostics