In custom zipper manufacturing, broken supply chains are a critical business risk. They cause unpredictable delays and quality inconsistencies that compromise product integrity. ZIZIP offers a direct solution through its vertical integration model. By internally managing the entire manufacturing process, ZIZIP provides the foundation for steady quality and efficient service.

Key Takeaways

Vertical Integration ensures batch consistency and full traceability by controlling 100% of the production process, from raw materials to final validation.

Lead times are guaranteed to be 50% faster than the industry average, supported by automated production lines and streamlined internal logistics.

Performance is backed by verifiable data (e.g., 970 N strength, 2,000+ cycles), ensuring extreme durability in mission-critical applications.

The model significantly mitigates supply chain risks and allows for quick responses to market needs, strengthening your competitive position.

Vertical Integration: The Engine for Quality and Control

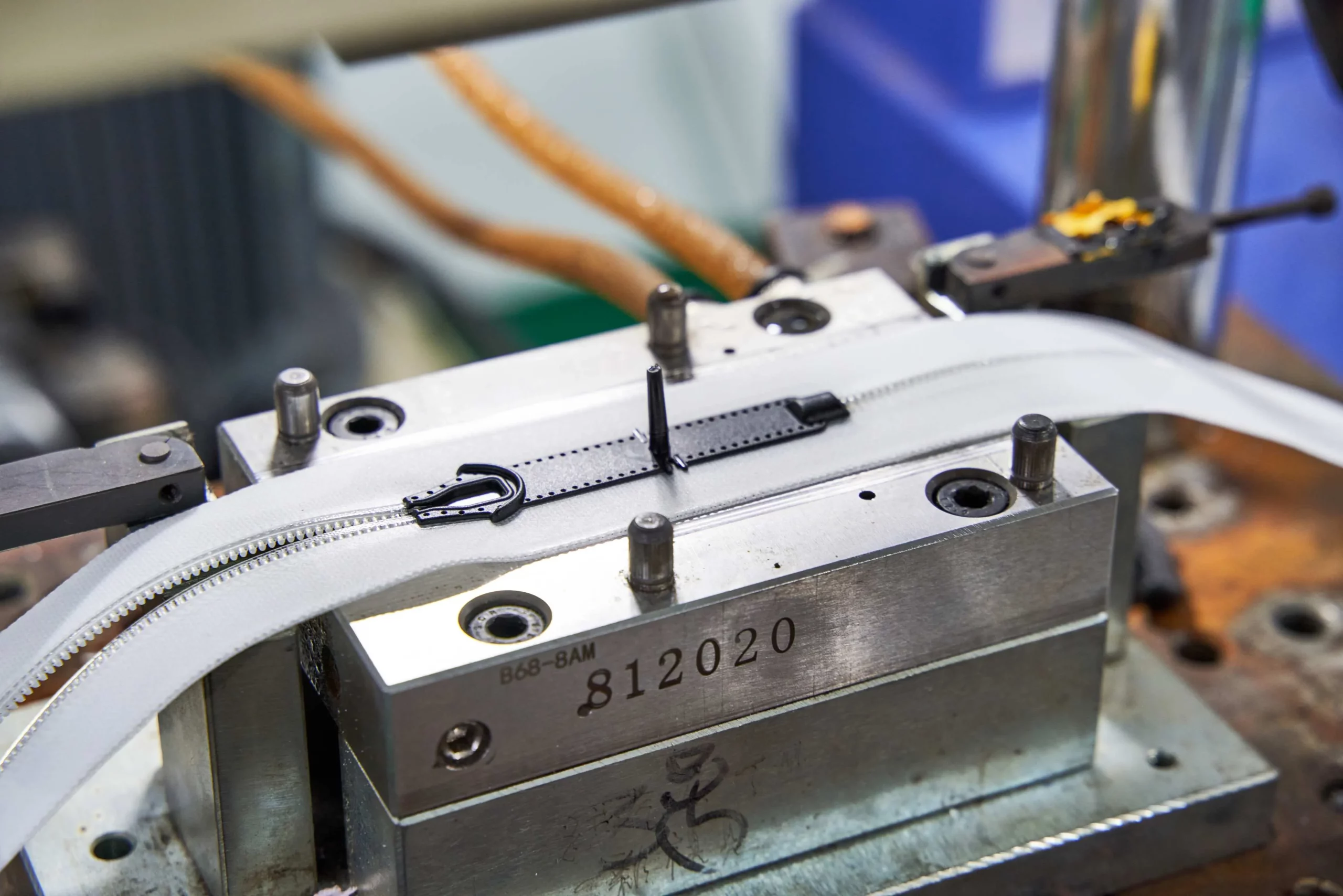

Vertical integration is a comprehensive strategic model in which a company owns and controls multiple stages of its own supply chain—from raw material sourcing to final distribution. While adopting this complex structure requires substantial internal investment, ZIZIP utilizes this model to maximize control, visibility, and operational efficiency, which are prerequisites for guaranteeing predictable quality and service in custom manufacturing.

Definition & Mechanism

In simple words, vertical integration means a company runs many steps in its supply chain. This can happen through mergers, buying other companies, or creating new production methods. By doing this, you get better control over quality, costs, and delivery times.

Here’s how vertical integration works in custom zipper manufacturing:

Material Sourcing: ZIZIP manages high-quality material sourcing to fit client specifications.

Production Control: The manufacturing process is internally overseen to meet quality standards.

Quality Assurance: ZIZIP implements strict inspection methods at each step to maintain quality.

Distribution Management: ZIZIP manages logistics to ensure timely delivery to the customers.

Benefit 1: Batch Consistency & Traceability

One big benefit of vertical integration is the steady quality it gives. When the production process is controlled internally, communication problems are avoided that happen in broken supply chains. This provides better visibility over production steps, helping you find any issues quickly.

Aspect | Vertically Integrated Supply Chains | Fragmented Supply Chains |

|---|---|---|

Communication | Stops communication problems by managing all processes in-house. | Has communication issues due to many partners. |

Visibility | Gives better visibility over production steps, allowing quick problem finding. | Lacks visibility, leading to possible unnoticed quality problems. |

Quality Assurance | Uses strict multi-step inspection methods to keep quality high. | Often has poor oversight, making quality problems harder to fix. |

With vertical integration, batch consistency and traceability are ensured.This means you can follow every part of your zippers, from raw materials to finished products. Quality issues can be quickly traced back to the source for immediate correction.

Benefit 2: Cost & Risk Mitigation

Vertical integration also helps lower costs and risks. By managing the supply chain, dependence on outside suppliers is reduced. This structure leads to significant savings through better buying power and improved cost management, which directly lowers overall operating costs.

Also, vertical integration reduces risks from supply chain problems. Internal management provides direct control over inventory, which cuts down the chances of running out or having too much stock. This flexibility allows for quick responses to market needs without incurring extra costs.

Core Advantage: Predictable and Faster Delivery

In custom zipper manufacturing, unpredictable lead time is a major challenge. Delays in component sourcing, manufacturing inefficiencies, and external shipping variables are common factors that erode project timelines. ZIZIP addresses these challenges directly. Our method utilizes data-driven strategies and automation to ensure we meet your custom zipper deadlines reliably.

Implementation Mechanism

ZIZIP’s promise for fast delivery stems directly from our vertical integration model. By eliminating uncertainties from broken supply chains, we guarantee lead times that are 50% faster than the industry average and offer support for 72 hr rush orders.

Our method is built on advanced automation and real-time control, ensuring quality remains steady while rapidly meeting your needs. We achieve this predictable speed through three key operational pillars:

Integrated Production Lines: Our lines handle every step of zipper creation. This integration cuts down delays and eliminates miscommunication between production stages.

Real-Time Monitoring: We use advanced systems to continuously track production progress, allowing us to spot and resolve potential bottlenecks before they affect your delivery times.

Centralized Collaboration: Our process includes direct, centralized communication for feedback and approvals. This asynchronous workflow saves valuable time and improves overall project management.

By utilizing these methods, ZIZIP ensures you receive your custom zippers quickly and reliably, allowing you to focus on your main business.

Quantifiable Reliability: Data That Proves Quality

Durability Metrics

ZIZIP confirms reliability using the following key, quantifiable measures:

Metric | Value |

|---|---|

Strength | 970N transverse tensile (38% > IPX5 compliance) |

Durability | 2,000+ reciprocating cycles (2× ASTM D2061) |

Environmental resilience | Zero delamination after -30°C/100°C thermal shock test reports (SGS/REACH) |

Global Compliance & Trust

ZIZIP’s commitment to quality is shown by compliance with ISO 9001:2015 standards and material traceability through certifications like REACH and OEKO-TEX®. By choosing ZIZIP, you get zippers that combine durability, strength, and compliance, ensuring your products perform well in any situation.

By combining vertical integration with data-backed reliability, ZIZIP eliminates supply chain uncertainty and provides the critical competitive edge needed to accelerate your products to market.

If you’re ready to transform your supply chain and explore how this reliable partnership can benefit your next project, we invite you to connect with our team.

Contact a ZIZIP technical expert today to discuss your project specifications and accelerate your time-to-market.

FAQ

What types of zippers does ZIZIP offer?

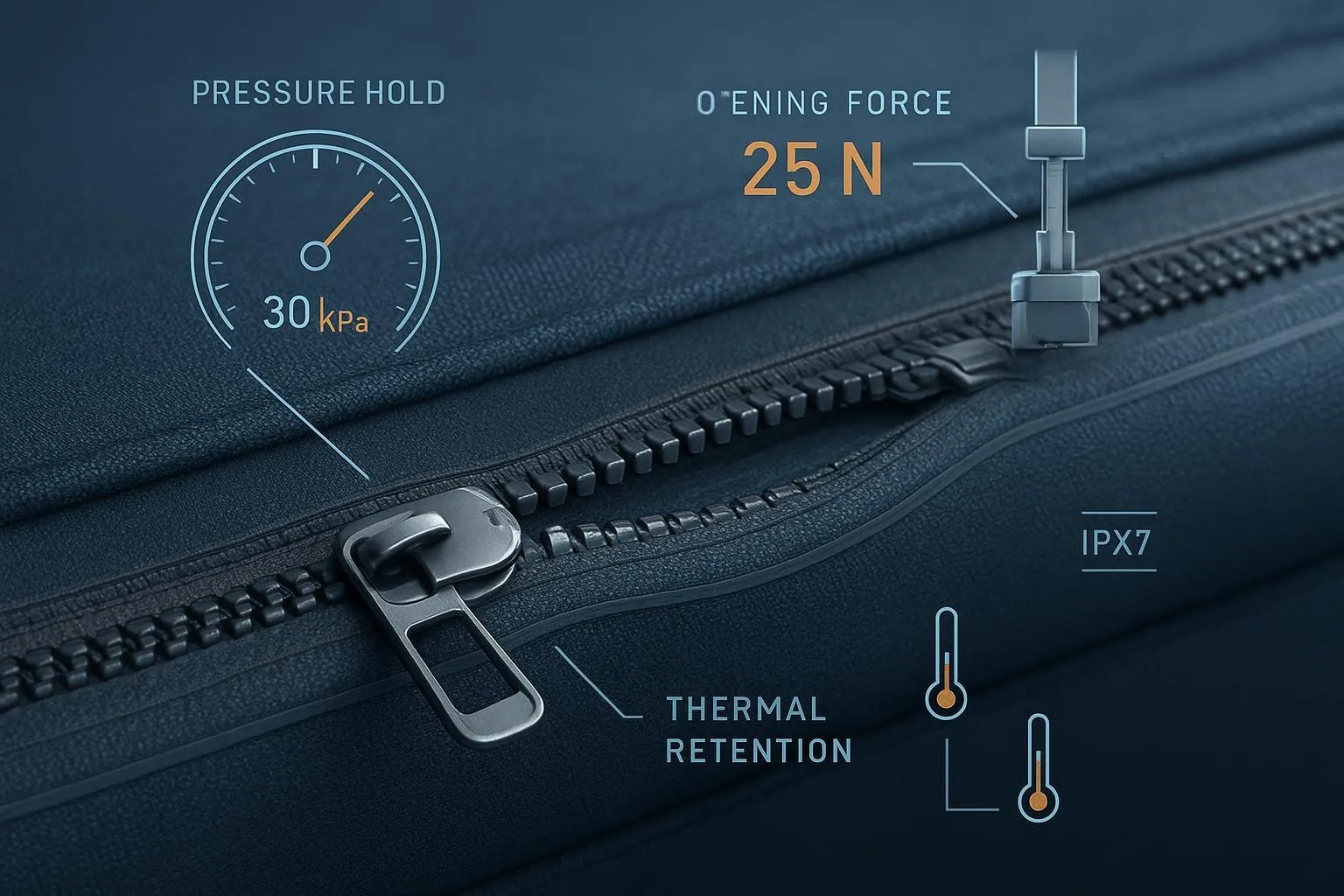

ZIZIP makes two main kinds of zippers. AquaSeal is for waterproofing. AeroSeal is for airtight uses. Each type is made for different environments and needs.

How does ZIZIP ensure quality in its zippers?

ZIZIP keeps a close eye on quality through vertical integration. This method lets you check every step of production. It helps make sure all zippers are reliable and consistent.

Can I customize my zipper order?

Yes! ZIZIP allows you to customize your zippers. You can choose the size, color, and design. Our engineers will help you create zippers for your specific project needs.

What industries benefit from ZIZIP zippers?

ZIZIP zippers are used in many industries. These include outdoor clothing, military, aerospace, and medical fields. Our products are made to handle tough environments.

How can I get a sample of ZIZIP zippers?

You can ask for free samples of ZIZIP zippers. Just reach out to our customer service team. They will help you with the process.