Dual-Track AeroSeal™ Airtight Zipper

Redundant Sealing for Mission-Critical Applications and Ultimate IPX8+ Protection.

The Dual-Track Aeroseal™ is the ultimate choice for environments where failure is not an option.

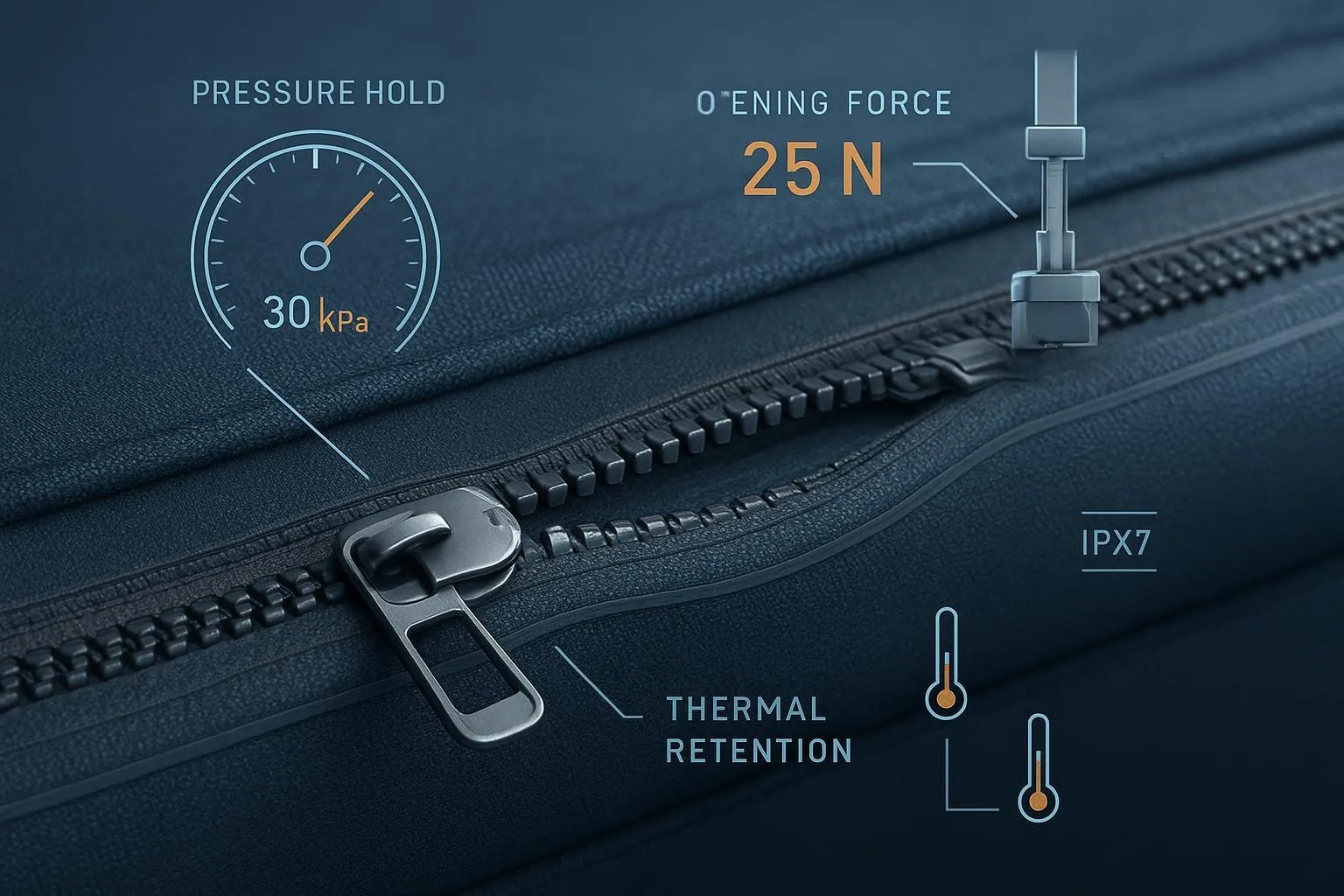

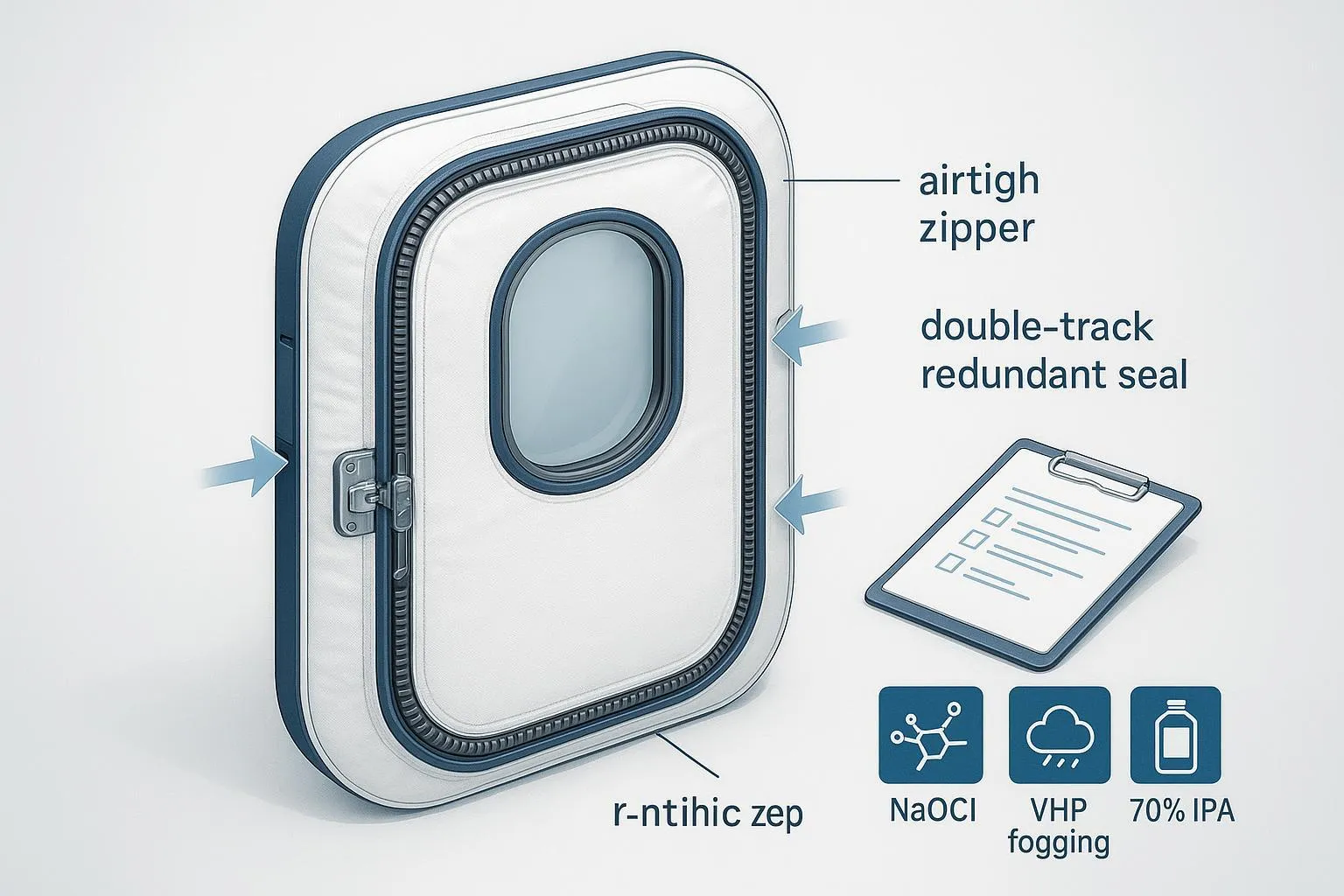

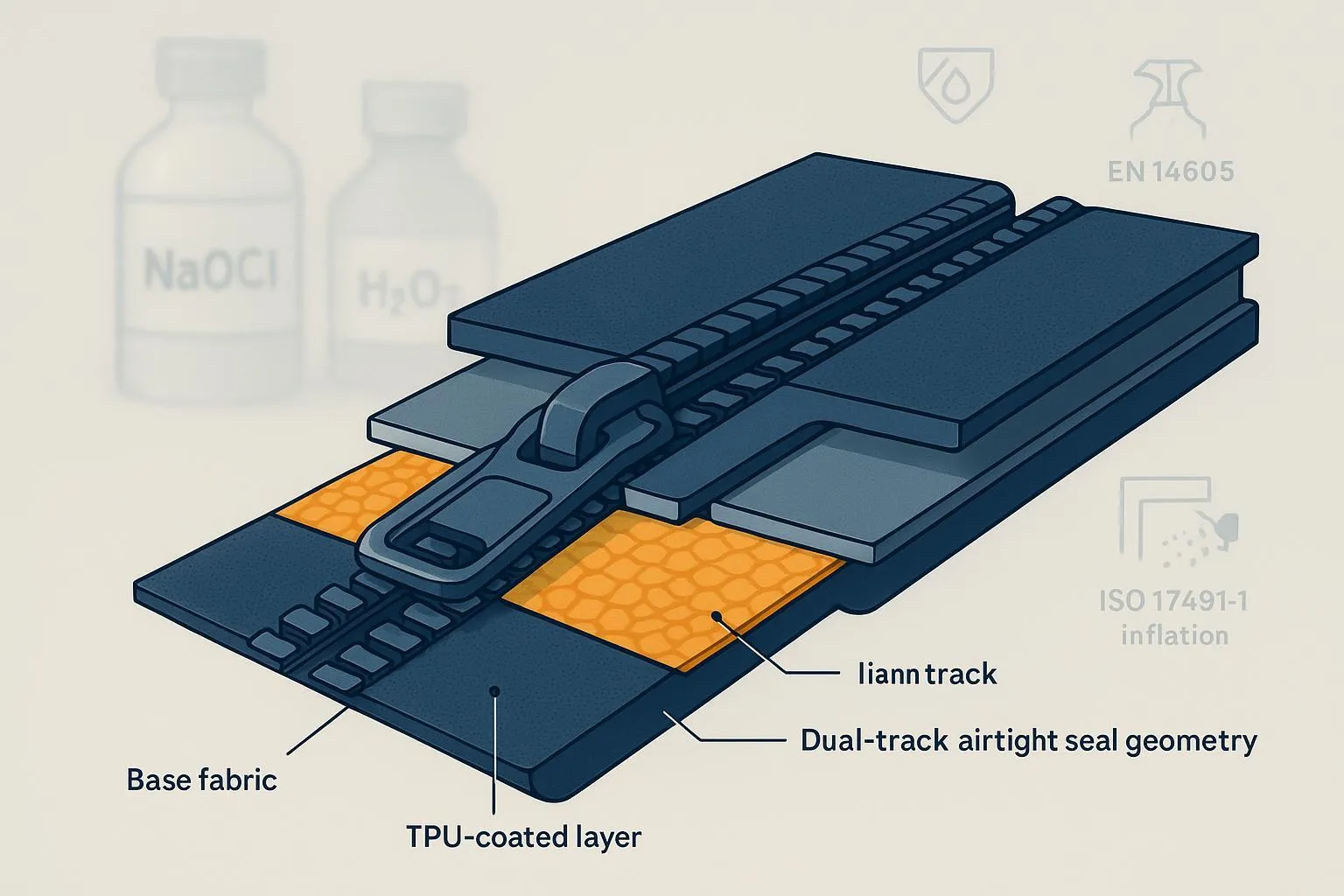

Its robust design is built with a redundant set of parallel, interlocking teeth, providing the highest level of security and a hermetic seal. The zipper has been certified with an IPX8+ waterproofing rating, making it a definitive solution for deep-sea diving, hyperbaric chambers, and critical HAZMAT containment applications where absolute reliability is paramount.

Key Feature

IPX8+ Redundant Sealing

The dual-track design provides a secondary, backup seal, ensuring unparalleled protection against ingress, even under extreme pressure.

Extreme Pressure Resistance

Maintains hermetic integrity at pressures up to 120kPa, far exceeding the 100kPa industry benchmark for critical applications.

Exceptional Tensile Strength

With a transverse strength of 1673 N, it is over 67% stronger than the standard, built to withstand extreme external forces.

Mission-Critical Durability

Engineered to withstand 1500 reciprocating cycles under load, guaranteeing reliability for equipment where performance is a matter of safety.

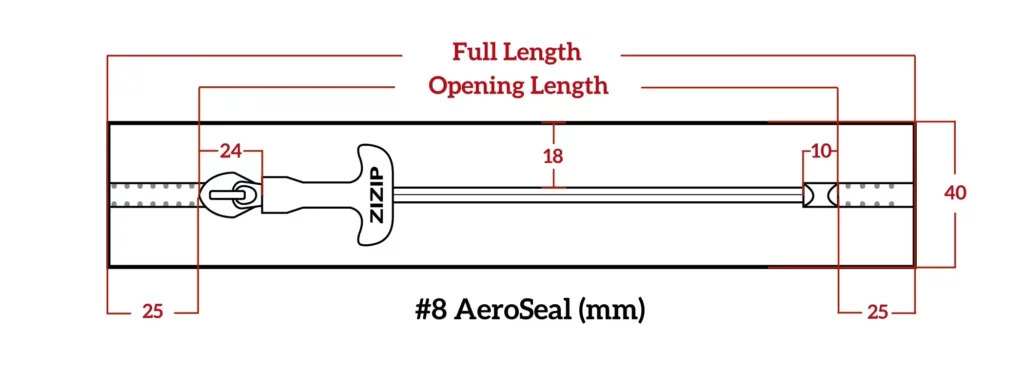

Find the Right AeroSeal™ Size

Technical Report

| Inspection Item | Test Result | Compliance Threshold |

| Transverse Tensile Strength | 660N | >500N |

| Slider Initial Pull Force | 35N | <50N |

| Smooth Sliding Performance | 30N | <40N |

| Abrasion Resistance | 60 continuous reciprocating cycles | 50 continuous reciprocating cycles |

| Hermetic Sealing | Maintains leak-free integrity at 20kPa for >=9 seconds | Maintains leak-free integrity at 20kPa for 5 seconds |

| Tooth-to-Tape Peel Strength | 28-35N/27-38N/30-41N | Tooth Engagement Width 1.5cm, >=20N |

| Tape-to-Finishing Peel Strength | 24-33N/27-36N/25-33N | Tape Body Width 1.5cm, >15N |

| Reciprocating Test under Load | 700 cycles | >500 cycles |

| Waterproof Rating | IPX7 (SGS) | GB/T 4208-2017 IPX7 |

| Water Penetration Test | No leakage after 10 min in inverted position w/ 5kg water load | No leakage after 5 min in inverted position w/ 3kg water load |

| Slider Hardness | 115HV0.3 | Vickers-Hardness 0.3 Test (>80 HV0.3) |

| Slider Load Capacity | 150N | >100N |

| Slider Tensile Strength | 145N | >100N |

| Pull Tab Torque Resistance | 135N | >100N |

| Pull Tab Extraction Strength | 145N | >100N |

AeroSeal Airtight Zipper

AquaSeal Waterproof Zipper

Get A Free Quote

Trusted in the World's Most Demanding Environments

The definitive choice for underwater drones (ROVs), scientific instruments, and other submersible electronic enclosures.

Provides a reliable, pressure-tight seal for medical hyperbaric oxygen chambers and isolation units.

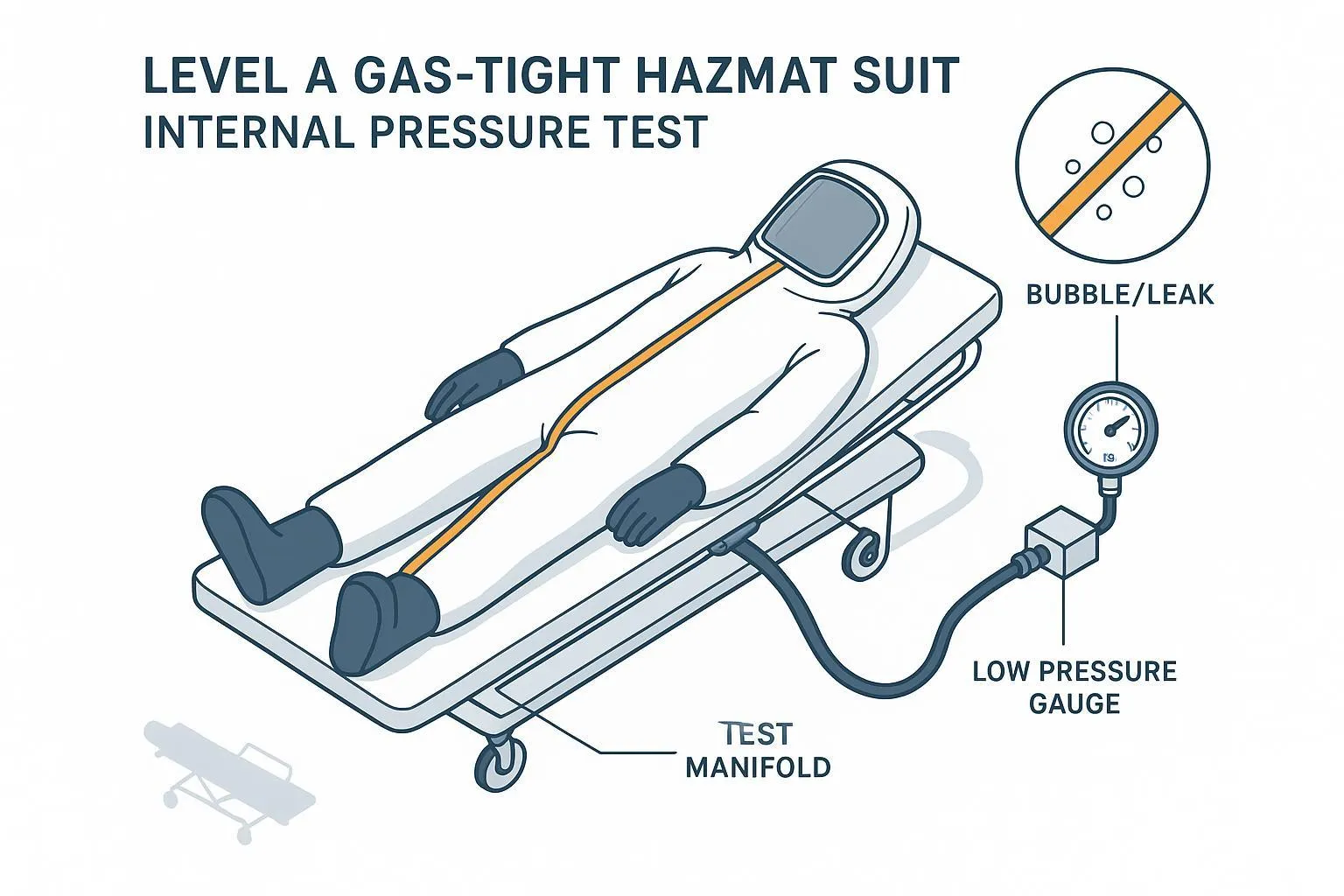

Used for critical containment bags and suits where absolute sealing against chemical or biological agents is required.

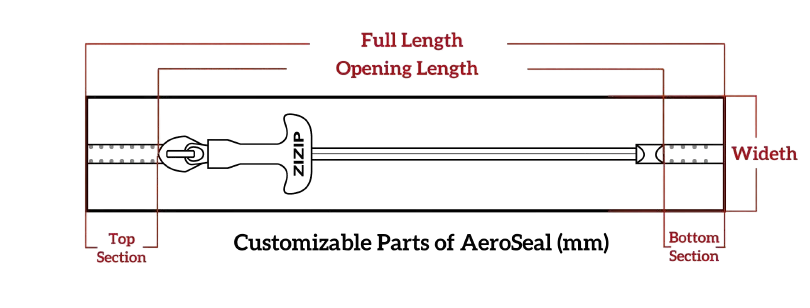

Custom Engineered Sealing Solutions (OEM/ODM)

Our vertically integrated manufacturing process gives us complete control over production, allowing us to offer extensive customization for our partners. We work directly with your design and engineering teams to create waterproof and airtight zippers that meet your product’s exact technical and branding specifications.

Millimeter-Perfect Customization

Precision is paramount. We manufacture zippers to your exact length specifications, achieving millimeter-level accuracy. This dedication ensures seamless integration into your application, significantly minimizing material waste, and simplifies your overall assembly process.

Custom Colors for Brand Matching

Match your brand’s exact color palette. We provide custom color matching for both the zipper tape and the TPU coating based on the Pantone (PMS) color system, ensuring seamless integration with your product’s design.

Specialized Puller Designs with Your Logo

We offer a variety of industrial-grade zipper puller options tailored for different application scenarios, combining functionality, ergonomics, and visual appeal, with the option to customize brand logos upon request.

Custom Material & Coating

Engineered for your specific application. Our zippers are built with high-strength

Polyester fabric tape and coated with a high-performance TPU (Thermoplastic Polyurethane) layer. We work with you to ensure the material combination provides the optimal balance of flexibility, durability, and sealing performance.Consult our team of engineers and we will deliver the optimal solution tailored to your specific needs.

SUPPORT & FAQ

Minimum Order Quantity (MOQ)

Complimentary samples

Verified Test Data & Quality Certifications

We provide comprehensive documentation, including SGS Waterproof Test Reports, REACH Compliance Reports, and ISO Certifications, ensuring adherence to global standards. Furthermore, each zipper batch undergoes rigorous internal self-inspection by our dedicated factory Quality Control department. For detailed reports and further information, please contact our customer service team.

Technical Support

- Bespoke Sealing Solution Design: For highly specialized application scenarios, including demanding sectors like aerospace equipment, our engineers develop bespoke sealing plan designs.

- Material Compatibility Assessment: To ensure optimal integration, clients are invited to submit their application materials for a thorough compatibility assessment.

- Precision Installation Guidelines: Following material compatibility confirmation, our technical team provides bespoke processing parameters.

- Zipper Care & Maintenance Protocols: Comprehensive guidelines are provided for the daily maintenance and long-term care of ZIZIP zippers.

Payment Method And Terms

After-sales Service

- Warranty Period: This product is covered by a 30-day limited warranty, effective from the date of goods receipt. Replacement units are available, and supplementary repair strips will be provided.

- Warranty Coverage: This warranty specifically covers performance issues such as water leakage, air leakage, or broken zipper teeth, directly attributable to material defects or manufacturing processes.

- Exclusions from Warranty:

-User-Induced Damage: Damage resulting from misuse, including but not limited to cutting, excessive force, or exposure to corrosive chemicals.

-Improper Maintenance: Issues arising from non-adherence to recommended maintenance guidelines (e.g., zipper obstruction due to uncleaned debris or sand).

-Unauthorized Alterations: Any repairs or modifications performed by third parties not authorized by ZIZIP.

Related News

Designing a soft cooler or insulated delivery bag lives and dies by its closure. The wrong zipper can sabotage airtightness, […]

Positive‑pressure isolation pods and hyperbaric chambers live or die by the integrity of their closures. When a zipper is the […]

Chemical protection fails at the weakest interface—often the closure. If your garments face repeated contact with MEK, acetone, toluene, and […]

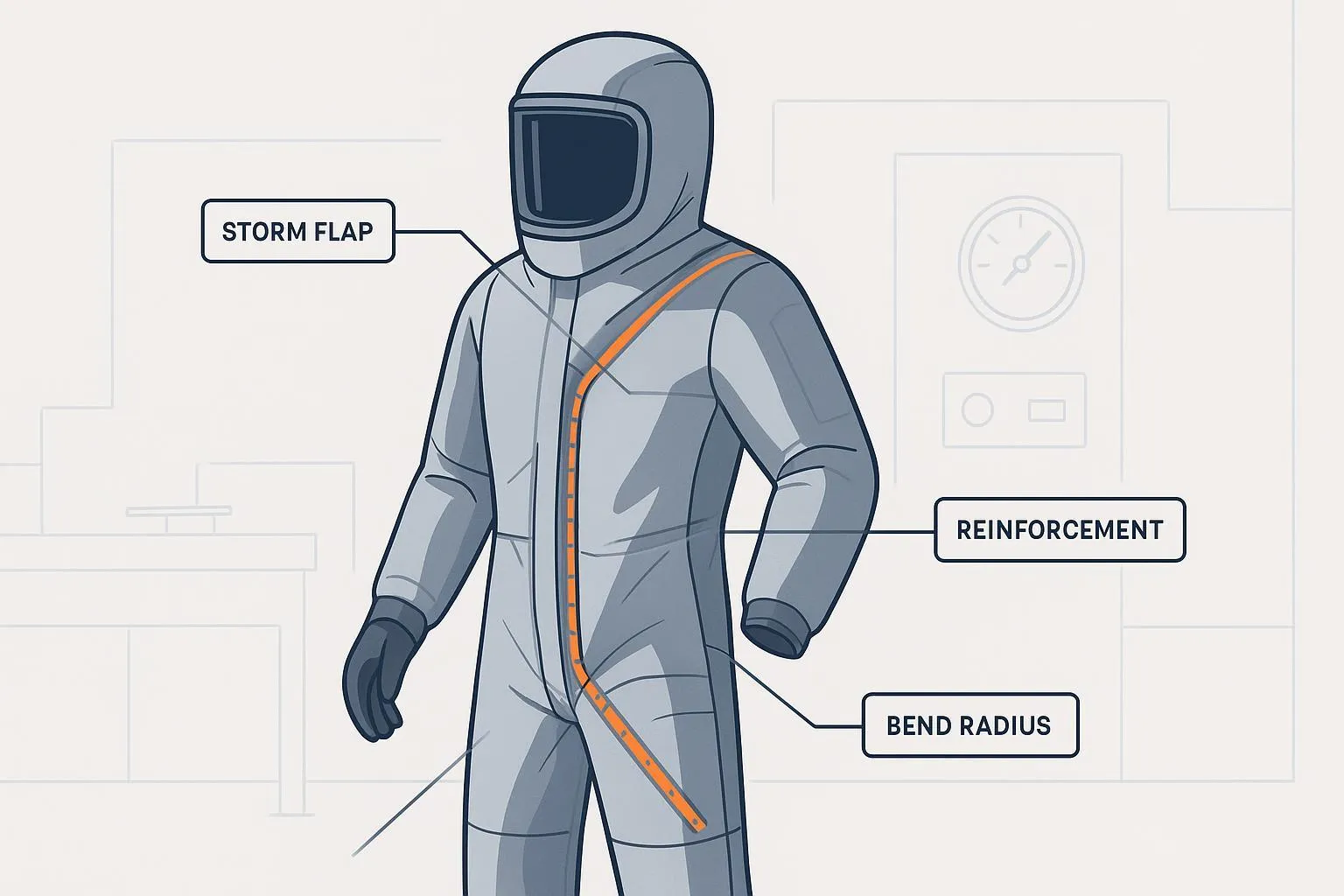

Designing a zipper route on a Type 1 gas‑tight suit is a balancing act. You need a path that lets […]

Designing an encapsulated protective suit is a constant balancing act: users want fast, intuitive donning and doffing, while engineering demands […]

Designing and certifying gas‑tight HAZMAT ensembles lives or dies on the integrity of the closure system. If you’re an OEM […]