Airtight zippers are very important for medical and bio-containment gear. They help keep equipment safe and working well in tough situations. By following IPX7 and IPX8 waterproof standards, these zippers give strong protection against water and harmful substances.

Here’s how they help with compliance:

Feature | Description |

|---|---|

Material | TPU (Thermoplastic Polyurethane) |

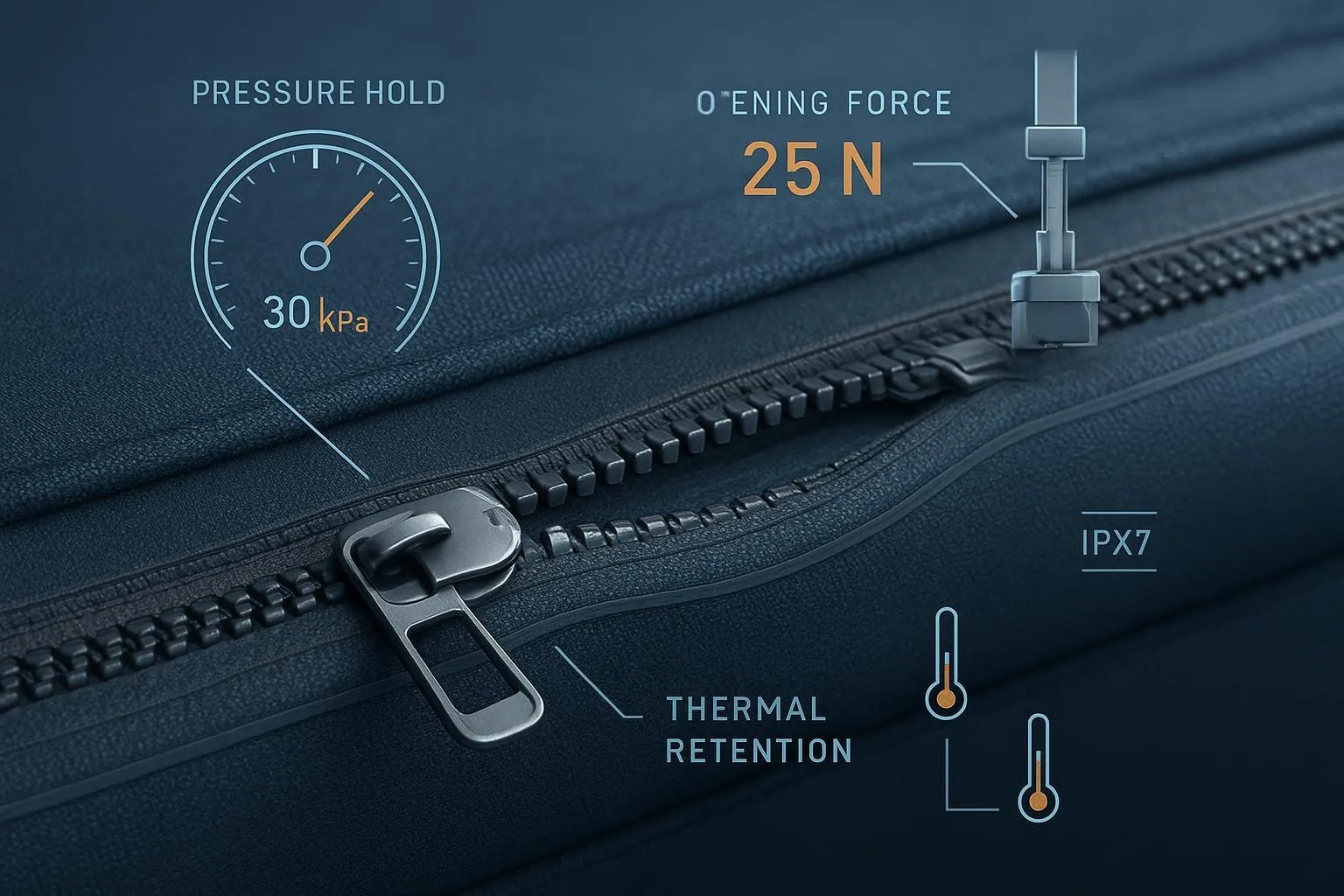

Waterproof Grade | IPX7 (SGS certificate) |

Airtight Pressure | Holds air pressure of 30KPA |

Construction | Airproof and watertight with smooth surface |

Compatibility | Can be hot welded or RF welded with different thermoplastic materials |

Functionality | Provides the best waterproof function, flexible and durable |

With these features, you can trust that your medical gear will stay strong and work well in tough conditions.

Key Takeaways

Airtight zippers create a strong seal against air and liquids. This keeps medical and bio-containment gear safe.

IPX7 and IPX8 ratings are important for waterproofing. IPX7 can handle 1 meter of water for 30 minutes. IPX8 gives even better protection.

Using strong materials like TPU makes zippers last longer and bend easily. This is great for tough medical settings.

Regular tests, like checking pressure and immersion, make sure zippers are safe and work well.

You can customize airtight zippers for special medical needs. This helps create the right solutions.

Airtight Zippers Overview

Definition and Importance

Airtight zippers are special closures. They create a complete seal against air, liquids, and tiny particles. These zippers are very important for keeping medical and bio-containment gear safe. You can trust airtight zippers to seal better than regular zippers.

Here’s a comparison of their key features:

Feature | Airtight Zipper | Standard Zipper |

|---|---|---|

IPX7 Waterproof Certified | Yes | No |

Airtightness | No leaks under pressure | Limited sealing |

Tensile Strength | 1205 N (33% stronger than standard) | 900 N compliance |

Material Science | High-quality TPU for durability | Regular materials |

The advanced materials and design of airtight zippers help them meet strict needs in important places. You can count on these zippers to stay strong under pressure and tough conditions.

Applications in Medical Gear

Airtight zippers are used a lot in medical settings. They are key for keeping things safe and clean where germs can be a big problem. Here are some common uses:

High-isolation protective suits

Biosecurity lab protective gear

These uses have special needs for the zippers. For example, high-isolation protective suits must have a perfect seal to keep things safe and clean. The table below shows the needs for different uses:

Application Type | Requirements |

|---|---|

HAZMAT and Medical Containment | Strong, resistant to the environment, and stops chemicals and germs. |

High-Isolation Protective Suits | Must have a perfect seal to keep safety and cleanliness in critical areas. |

IPX7/IPX8 Standards Explained

Overview of Waterproof Ratings

Knowing about waterproof ratings is very important. It helps you choose the right gear for medical use. The IPX7 and IPX8 ratings show how well a device can keep out water. Here’s a simple look at these ratings:

Rating | Immersion Depth | Duration | Testing Conditions |

|---|---|---|---|

IPX7 | 1 meter | 30 minutes | The device must be off, all ports closed, and checked for water after testing. |

IPX8 | Greater than 1 meter | Set by the manufacturer | Continuous immersion under specific conditions set by the manufacturer. |

IPX7: The device must handle being in 1 meter of water for 30 minutes without water getting inside.

IPX8: Set by the manufacturer, meaning it can go deeper or last longer than IPX7, good for special uses.

These ratings make sure your medical gear works well in wet places, like during cleaning.

Implications for Medical Equipment

The IPX7 and IPX8 ratings are very important for medical gear. Here are some key points to think about:

Safety and Reliability: IPX7 and IPX8 ratings mean devices can survive being in water. This is very important for working in wet areas, like during cleaning.

Continuous Submersion: IPX8 means a device can stay underwater for a long time beyond 1 meter. This is crucial for medical gear that might be in water for a long time.

Thorough Validation: IPX8 needs careful checking for long or deep submersion. This shows how important it is for reliable medical uses.

Resistance to Cleaning Agents: Medical devices used in cleaning must resist being in water and cleaning products. This keeps them strong and reliable over time.

Regulatory agencies check medical gear to make sure they meet these standards through strict testing. The process includes:

Testing Phase | Details |

|---|---|

Immersion Phase | The device is put underwater in a controlled setting for 30 minutes to check water resistance. |

Post-Test Analysis | Visual checks for water inside, electrical tests, and checking if it works properly. |

Test Parameters | Minimum depth of 1 meter, time of 30 minutes, and controlled water temperature. |

Pre-Test Preparation | The device is prepared, seals checked, and basic function tests are done. |

By following IPX7 and IPX8 standards, you make sure your airtight zippers and medical gear stay safe and reliable in tough situations.

Materials for Airtight Zippers

Suitable Materials and Properties

When picking materials for airtight zippers, you need to make sure they are high quality. The most common material is TPU (Thermoplastic Polyurethane). TPU is very flexible and strong, which makes it great for medical use. Here’s a table showing important properties of zipper materials:

Property | Test Method | Typical Result |

|---|---|---|

Thickness | ASTM D1777 | 6.3 mils |

Basis Weight | ASTM D3776 | 2.0 oz/yd² |

Burst Strength – Mullen | ISO 2758 | 65.3 psi |

Seam Strength | ASTM D1683 | 34 lbf |

Breaking Strength – Grab (MD) | ASTM D5034 | 28.7 lbf |

Breaking Strength – Grab (CD) | ASTM D5034 | 31.5 lbf |

Water Impact Penetration | AATCC 42 | <0.2 g H₂O |

Wearing Apparel Flammability | 16 CFR 1610 | Class 1 |

These properties help the zippers work well in bio-containment areas. The mix of strength and water resistance makes TPU a great choice.

Compliance with Medical Standards

To make sure airtight zippers meet medical standards, you need to follow certain tests. Here are some important tests:

Fabric Hydrostatic Tests: Check how much water pressure the material can handle before it leaks.

Assembled-Bag Testing: Done under IPX rules, including fake rain and immersion tests.

Immersion Tests: Involves putting the bag underwater to check for leaks, usually lasting 30 minutes at about 3 feet deep.

Zipper Submersion and Cycle Tests: Test how zippers work when submerged in water.

Weight-Difference and Paper-Towel Witness Checks: Measure water entry by checking weight changes and using paper towels to find leaks.

By following these testing methods, you can ensure your airtight zippers meet medical standards. This is very important for keeping safety and reliability in medical uses.

OEM Design Guidelines for Zizip

Key Design Considerations

When designing airtight zippers for medical and bio-containment gear, you need to think about several important factors. These factors affect how well the zippers work in critical situations. Here’s a summary of key design features:

Feature | Description |

|---|---|

Sealing Performance | Dual-track design gives an extra seal for better protection. |

Pressure Resistance | Keeps a tight seal at pressures up to 120kPa, which is better than industry standards. |

Tensile Strength | Has a strength of 1673 N, making it over 67% stronger than regular zippers. |

Durability | Made to last for 1500 cycles under load for dependable performance. |

Customization Options | Many customization choices are available to fit specific needs and branding. |

You can improve the performance of your airtight zippers by choosing high-quality materials. Think about using TPU, polyester, and reinforced structures. These materials help the zippers work better in tough conditions, making sure they meet the needs of medical settings.

Ensuring Functionality and Safety

To make sure airtight zippers work well and are safe in high-risk medical areas, focus on important design features. These features help stop leaks and ensure the zippers work reliably under pressure. Here are some key elements to think about:

Key Feature | Description |

|---|---|

Integrated Weldable Flange | Wide TPU U-channel flanges make it easy to weld strongly, creating a better bond than sewing. |

Monolithic Seal | Removes needle holes from stitching, which can leak, giving a truly continuous and reliable seal. |

Robust IPX7 Airtight Core | Built around a strong zipper chain, ensuring high performance against pressure and water. |

Enhanced Structural Integrity | The wide welded area spreads stress evenly across the material, making the final product more durable. |

By adding these design features, you can make sure your airtight zippers offer the needed protection and reliability in tough medical uses. The mix of TPU, polyester, and reinforced structures boosts the zippers’ performance, making them fit for extreme conditions.

Testing and Quality Assurance

Methods for Testing Airtight Zippers

Testing airtight zippers is very important. It helps make sure they work well in medical uses. You can use different methods to check how effective they are:

Hydrostatic Pressure Testing: This test checks how much water pressure the zipper can handle. You put the zipper in water and push down to see if it leaks.

Cycle Testing: This means opening and closing the zipper many times while it is under pressure. You want to see if it still seals well after lots of uses.

Immersion Testing: You put the zipper in water for a set time, usually 30 minutes, to look for leaks. This shows how it works in real-life situations where it might get wet.

Environmental Testing: This test checks how the zipper works in extreme temperatures. You expose it to both hot and cold conditions to make sure it still works.

Importance of Quality Control

Quality control is very important when making airtight zippers. It makes sure every zipper meets safety and performance standards. Here are some key reasons why quality control is essential:

Safety Assurance: You need to make sure the zippers seal well. This is especially important in medical uses where germs can be a big risk.

Consistency: Quality control helps keep production uniform. Each zipper should work the same way, no matter when or where it was made.

Regulatory Compliance: Many industries have strict safety rules. Quality control ensures your zippers follow these rules, helping you avoid legal problems.

Customer Trust: When you provide high-quality products, you gain trust from your customers. They will depend on your zippers for important tasks, knowing they can count on them.

By using careful testing and quality control steps, you can make sure your airtight zippers work reliably in tough situations.

Customer Success Stories

Zizip Collaborations

Zizip has teamed up with different groups to improve medical and bio-containment gear. These partnerships show how Zizip’s airtight zippers fit the needs of tough environments. Here are some important collaborations:

Military Applications: Zizip worked with military companies to create airtight zippers for protective suits. These zippers help keep soldiers safe from dangerous materials.

Medical Equipment Manufacturers: Zizip joined forces with top medical device makers. They designed zippers that keep surgical tools clean and safe from germs.

Aerospace Industry: Zizip partnered with aerospace companies to make zippers for equipment used in extreme conditions. These zippers help protect sensitive instruments.

These partnerships show Zizip’s commitment to quality and new ideas in sealing technology.

Impact on Product Reliability

Using Zizip’s airtight zippers greatly boosts product reliability in many uses. Here’s how:

Enhanced Protection: Airtight zippers create a full seal against liquids, gases, and tiny particles. This is very important for medical and military gear, where safety is key.

Durability: Zizip zippers go through tough testing to make sure they can handle rough conditions. They keep working well even after being in extreme temperatures and heavy use.

User Confidence: When you pick products with Zizip’s airtight zippers, you feel more secure. You can trust that your gear will work reliably in important situations.

By focusing on quality and performance, Zizip makes sure its airtight zippers meet the highest standards. This commitment to excellence makes Zizip a top choice for industries that need reliable sealing solutions.

Choosing the right airtight zippers is very important for medical uses. These zippers help keep things safe and reliable in critical areas. The IPX7 and IPX8 standards are key for stopping water from getting in. IPX7 lets items be underwater up to 1 meter for 30 minutes, while IPX8 offers even better protection. This level of safety is crucial for medical gear that might get wet during cleaning or from the environment. Also, picking the right materials and following OEM design rules improves how well your equipment works. By focusing on these points, you can make sure your medical gear stays effective and trustworthy.

FAQ

What are airtight zippers?

Airtight zippers make a full seal against air, liquids, and tiny particles. They are very important for medical and bio-containment gear. They help keep things safe and reliable in critical places.

How do IPX7 and IPX8 ratings differ?

IPX7 ratings let items be underwater up to 1 meter for 30 minutes. IPX8 ratings give even better protection. They allow for deeper or longer immersion based on what the manufacturer says.

What materials are used in airtight zippers?

Airtight zippers usually use TPU (Thermoplastic Polyurethane). This material is flexible and strong. It helps create a good seal and resists tough conditions, making it great for medical uses.

How can I ensure the quality of airtight zippers?

You can check quality by choosing zippers that go through strict testing. Look for tests like hydrostatic pressure and cycle testing. Also, find certifications like IPX7 and IPX8 to show they are reliable.

Are customization options available for airtight zippers?

Yes, many makers provide customization choices for airtight zippers. You can change sizes, colors, and materials to fit specific needs and branding.