Airtight Zipper

A high-performance Aeroseal airtight zipper from a trusted supplier, offering a robust IPX7 seal for demanding applications.

- Robust IPX7 Airtight Seal: Delivers complete protection against liquid and gas ingress, certified for full immersion.

- High Tensile Strength: Features a transverse strength of 970N, significantly exceeding the >700N industry requirement.

- Exceptional Durability: Proven to withstand 1100 reciprocating cycles under load, nearly double the standard of 600 cycles.

- Fully Customizable: Available in a range of colors, including beige, to match your specific product design and branding needs.

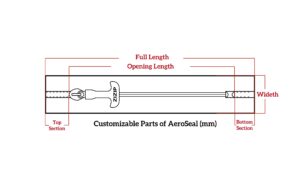

Custom Details Of Beige Aeroseal Airtight Zipper

Aeroseal Airtight Zipper Technical Data Sheet

| Inspection Item | Test Result |

Compliance Threshold

|

| Transverse Tensile Strength | 970N | >700N |

| Slider Initial Pull Force | 41N | <50N |

| Smooth Sliding Performance | 30N | <40N |

| Abrasion Resistance | 70 continuous reciprocating cycles |

50 continuous reciprocating cycles

|

| Hermetic Sealing | Maintains leak-free integrity at 20kPa for >14 seconds |

Maintains leak-free integrity at 20kPa for 10 seconds

|

| Tooth-to-Tape Peel Strength | 23-35N/23-36N/24-41N |

Tooth Engagement Width 1.5cm, >20N

|

| Tape-to-Finishing Peel Strength | 24-33N/27-36N/25-33N |

Tape Body Width 1.5cm, >15N

|

| Reciprocating Test under Load | 1100 cycles | >600 cycles |

| Waterproof Rating | IPX7 (SGS) |

GB/T 4208-2017 IPX7

|

| Water Penetration Test | No leakage after 10 min in inverted position w/ 5kg water load |

No leakage after 5 min in inverted position w/ 5kg water load

|

| Slider Hardness | 115HV0.3 |

Vickers-Hardness 0.3 Test (>80 HV0.3)

|

| Slider Load Capacity | 170N | >100N |

| Slider Tensile Strength | 165N | >100N |

| Pull Tab Torque Resistance | 345N | >200N |

| Pull Tab Extraction Strength | 255N | >150N |

Inquire About Custom Aeroseal Zippers

Beige Aeroseal Airtight Zipper Detail Display

FAQ

Related Products

Related News

If your packs work around water—kayaking re‑entries, canyon pools, river crossings, wet SAR logistics—short, unexpected immersions are not edge cases. […]

Designing a soft cooler or insulated delivery bag lives and dies by its closure. The wrong zipper can sabotage airtightness, […]

Heading out for casual kayaking or a weekend camp and just need fast, reliable guidance? This checklist prioritizes ease of […]

Positive‑pressure isolation pods and hyperbaric chambers live or die by the integrity of their closures. When a zipper is the […]

Chemical protection fails at the weakest interface—often the closure. If your garments face repeated contact with MEK, acetone, toluene, and […]

Designing a zipper route on a Type 1 gas‑tight suit is a balancing act. You need a path that lets […]

Designing an encapsulated protective suit is a constant balancing act: users want fast, intuitive donning and doffing, while engineering demands […]

Designing and certifying gas‑tight HAZMAT ensembles lives or dies on the integrity of the closure system. If you’re an OEM […]