Validating how well zippers work is very important. This is to make sure products are reliable when they need to be waterproof and airtight. Recent studies show that 90% of waterproof bag problems happen at closures, like zippers. This highlights the necessity for strict testing methods such as IPX and pressure testing. These tests check if zippers, like the AeroSeal Airtight and AquaSeal Waterproof models, can handle tough conditions. By conducting these tests, manufacturers can ensure their zippers will perform effectively in various applications, from outdoor gear to aerospace components.

Key Takeaways

Testing zippers is very important. It makes sure they are waterproof and airtight. This is especially true for outdoor gear and marine equipment.

IPX ratings help you pick the right zipper. They show how well a zipper can resist water in different situations.

Regular pressure testing checks if zippers can handle tough conditions. This makes them last longer and work better.

Zizip‘s AquaSeal and AeroSeal zippers meet high standards. They give you dependable waterproof and airtight options.

Buying high-quality zippers makes customers happier. It also saves money in the long run by needing fewer replacements.

Importance of Zipper Testing

Waterproof and Airtight Performance

Zippers are very important in many products. This is especially true for items made for tough conditions. You find zippers in outdoor gear, marine equipment, work clothes, sportswear, and luggage. Each use needs zippers that work well to keep things safe and functional.

Here are some common uses where waterproof and airtight zippers are very important:

Application Type | Examples |

|---|---|

Outdoor gear | Jackets, tents, hiking bags, sleeping bags |

Marine equipment | Waterproof bags, wetsuits, boat covers |

Workwear | Protective suits and uniforms for tough jobs |

Performance sportswear | Made for swimming, cycling, or athletics in wet weather |

Luggage and backpacks | Needing extra protection from the weather |

Testing zippers makes sure they meet the right standards for how well they work and last. Regular zipper testing helps products last longer in outdoor and industrial uses. High-quality zippers must pass strict tests, like checking strength and smoothness. Each tooth must hold a certain weight to ensure the zipper lasts. It is important that zippers work smoothly without getting stuck.

Manufacturers focus on waterproof and airtight performance when designing zippers for many reasons. The main job of waterproof zippers is to stop water from getting in. They have sealed or laminated tape, welded seams, and special teeth that keep water out. Airtight zippers make a seal to keep air or gases out. They are often used in vacuum-sealed bags or airtight containers.

Modern waterproof zippers use new seam-sealing methods to keep water and moisture away. These new ideas are very useful in clothes and gear that need to breathe while staying water-resistant.

Testing methods include:

Test Type | Description | Purpose |

|---|---|---|

Tensile Test | Pull the zipper tape sideways. | Checks strength and how well it resists stretching or tearing. |

Slider Stress Test | Move the slider quickly back and forth. | Tests smooth operation and checks for jamming. |

Tooth Integrity Test | Push on closed zipper teeth. | Looks for strong interlocking without gaps. |

Water Resistance Check | Pour water on zippers like YKK AquaGuard®. | Tests how well they resist water. |

Zipper testing also helps solve common problems. Confusing waterproof and airtight standards can lead to choosing the wrong product. Problems in the meshing and coating can make zippers less waterproof. Bad slider design can cause leaks, hurting the sealing ability. Proper installation and use are very important to keep them working well.

IPX Testing Overview

IPX Ratings Explained

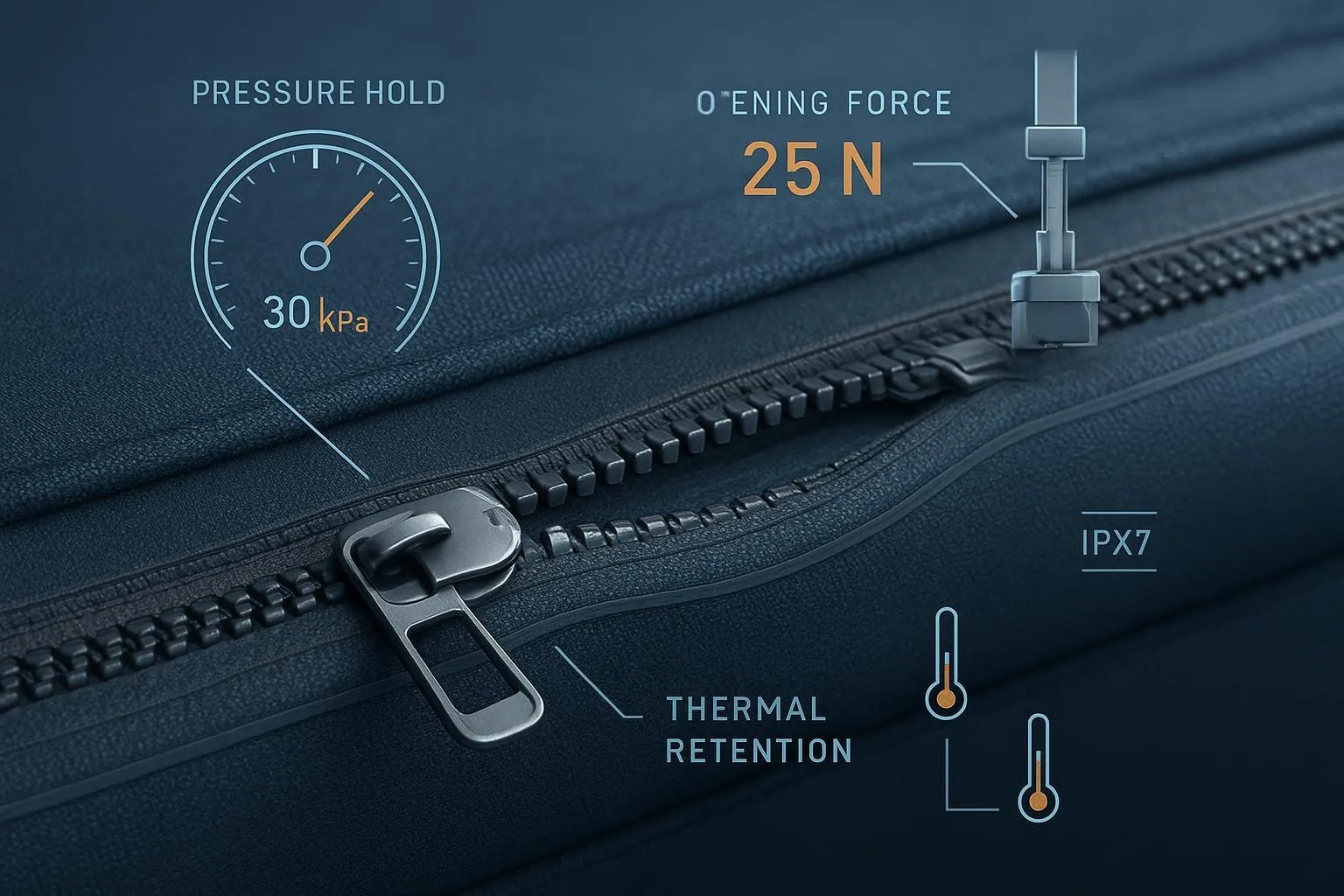

IPX testing is very important for checking how well zippers keep water and air out. This testing makes sure zippers can handle different weather conditions. IPX ratings are useful because they show how well a zipper stops water from getting in. These ratings help you pick the right zipper for your needs, especially in tough situations.

The IPX testing process has a few main steps:

Zipper Submersion Test – The zipper is put in water for 30 minutes to see if it leaks.

Cycle Test – The zipper is opened and closed over 200 times while under pressure, then tested again for waterproofing.

Pressure Test – Water pressure is applied to the zipper to check how strong it is under stress.

These steps make sure the zippers meet high standards for how well they work and last.

The IPX ratings match how zippers perform in real life. Here’s a list of the IPX levels and where they are usually used:

IPX Level | Water Resistance | Typical Use Case |

|---|---|---|

IPX3–4 | Splash- and rain-proof | Commuting, light outdoor use |

IPX5–6 | Jet spray and wave resistant | Kayaking, cycling, hiking |

IPX7 | 1m depth, 30 minutes | Swimming, snorkeling, accidental drop |

IPX8 | 30m depth, prolonged use | Diving, professional water activities |

These ratings help you see how well a zipper will work in different situations. For example, if you want to use a zipper in a diving suit, look for an IPX8 rating to make sure it can handle deep water.

New trends in zipper testing technology are making performance even better. Here are some cool advancements:

New materials and ways to make zippers are improving their performance.

Better TPU materials give more UV protection.

Self-lubricating seals need less maintenance and work smoother.

Smart zippers with sensors check seal strength and warn users about problems.

Advanced heat welding makes stronger and more precise seals.

These new ideas make sure zippers not only meet but also go beyond what is expected for waterproof and airtight uses.

Pressure Testing for Zippers

Durability and Performance Metrics

Pressure testing is very important for checking how strong and well zippers work. This testing makes sure zippers can handle different environments. Here are some common ways to test zippers:

Testing Method | Description |

|---|---|

Strength Testing | Checks how much force closed zipper parts can take to make sure they are strong enough. |

Durability Testing | Involves opening and closing zippers many times to mimic daily use, ensuring they still work well. |

Zizip’s AeroSeal zippers do really well in pressure tests. They set a high standard in the industry. For example, AeroSeal zippers can handle a pressure of 120 kPa, while the usual standard is only 100 kPa. Their strength reaches 1673 N, which is much higher than what is normally required.

Metric | Zizip AeroSeal | Industry Benchmark |

|---|---|---|

Pressure Resistance | 120 kPa | 100 kPa |

Tensile Strength | 1673 N | Standard Strength |

During pressure testing, several factors check how airtight and waterproof zippers are. These include:

Up to 1,500mm – fabric is not waterproof

1,500mm – 10,000mm – waterproof fabric according to European ISO standards

10,000mm – 20,000mm – outdoor industry standard for waterproof fabrics

20,000mm+ – completely waterproof fabrics made by top manufacturers.

Zipper performance testing also needs special adjustments and conditions. For example, the zipper is adjusted between water and air pressure chambers to get accurate results. The water level above the zipper must be 15 mm during testing, and air pressure is added based on how well the zipper is supposed to perform.

New tools for pressure testing have made checking zippers better. New devices can do many tests, like strength, tear resistance, and durability. These improvements help find problems and give ideas for fixing them. Easy-to-use designs make the testing process simpler for operators.

With Zizip’s focus on quality, you can trust that their AeroSeal zippers will work great in tough conditions.

Zizip’s Innovative Zipper Solutions

Zizip has two main product lines: AquaSeal and AeroSeal. These zippers are made to meet high standards for being waterproof and airtight. You can trust them for many uses, from outdoor gear to important equipment.

AquaSeal Waterproof Zippers

AquaSeal zippers give strong waterproof protection. They use high-density polyester fabric covered in TPU, which makes a sealing layer. This design stops water from getting in, making these zippers great for outdoor gear and waterproof bags. They have a strong IPX5 rating, meaning they resist water jets up to 100 L/min at 30 kPa. This makes them good for activities like kayaking and hiking.

AeroSeal Airtight Zippers

AeroSeal zippers are great for sealing out air and gases under high pressure. Their special dual-track design creates a strong barrier. This type of zipper is perfect for important uses, like diving suits and military gear. AeroSeal zippers keep their seal under pressures up to 120 kPa, which is much higher than normal needs.

Here’s a quick comparison of the benefits of both zippers:

Zipper Type | Benefits | Applications |

|---|---|---|

AquaSeal | Strong waterproof protection | Outdoor gear, marine uses, waterproof clothing |

AeroSeal | Airtight sealing for high pressure | Important uses needing strong barriers |

Zizip cares about quality control, so each zipper goes through tough testing. This ensures they last and work well in hard conditions. With over 30 utility patents in sealing technology, Zizip keeps finding new ways to make its zippers better.

Customer Success Stories

Many customers have seen the benefits of Zizip’s zippers. For example, Dollar Tree saved $125 million by improving how they buy supplies. T-Mobile changed its buying process to focus on value, helping 30,000 suppliers. These results show how Zizip’s new ideas lead to big improvements in performance and efficiency.

In conclusion, strong testing methods like IPX and pressure testing are very important for checking the quality of Zizip zippers. These tests make sure zippers can handle tough conditions, which is key for many uses. When you use high-quality zippers, you make customers happier and lower the chance of returns.

Here’s how strong testing affects your experience:

Impact Type | Description |

|---|---|

Better Customer Satisfaction | Good quality lowers the chance of returns from broken zippers. |

Long-Term Cost Savings | High-quality zippers might cost more at first but save money later by needing fewer replacements. |

Improved Brand Image | Using good zippers can boost a brand’s image, leading to more customer trust and loyalty. |

Choosing Zizip zippers is a smart choice for strength and performance, making sure your products stay waterproof and dependable.

FAQ

What is the difference between waterproof and airtight zippers?

Waterproof zippers stop water from getting in. Airtight zippers keep air and gases out. You use waterproof zippers for outdoor gear. Airtight zippers are used in things like diving suits.

How do I know which zipper to choose for my project?

Think about where your product will be used. For wet places, pick waterproof zippers. If you need to seal gas or air, choose airtight zippers.

Can I customize Zizip zippers for my specific needs?

Yes! Zizip lets you customize the length, width, and design. You can work with their engineers to make a zipper that fits what you need.

How do I maintain my zippers for long-lasting performance?

Keep zippers clean and free of dirt. Check them often for wear and tear. Lubricate them sometimes to keep them working smoothly and to avoid jamming.

What industries benefit from using Zizip zippers?

Zizip zippers are used in many industries. These include outdoor clothing, marine gear, aerospace, and military uses. Their sealing solutions work well in tough environments.