Airtight zippers are very important in industry and cold storage. They keep temperatures steady, which is important for sensitive products. But, you might have problems with sealing and managing loads. For example, keeping a good seal on freezer doors is key. This stops temperature changes. Opening doors too often can let warm air in. This causes temperature spikes. Also, equipment failures or bad weather can make it hard to manage temperatures. Good design and care of airtight zippers are needed for the best performance. This helps prevent losing products.

Key Takeaways

Airtight zippers are very important for keeping cold storage at the right temperature. They help protect sensitive products from going bad.

Picking the right materials for cold storage doors makes them last longer and handle weight better. This helps them deal with different pressures.

Regular maintenance is important. This includes oiling and checking seals. It helps airtight zippers last longer and work better.

High-speed doors with airtight zippers save energy. They do this by reducing air flow and keeping temperatures steady.

New zipper technology, like self-healing surfaces, can improve how well they work and help the environment in industrial uses.

Airtight Zippers Overview

Airtight zippers are very important in many industries. They help seal areas where leaks can be dangerous. You can find these zippers in inflatable shelters, medical tents, and systems that contain harmful materials. They keep air, gas, or liquid inside without leaking, which makes them very useful.

Zizip’s AeroSeal Zippers

Zizip makes high-quality airtight zippers, especially the AeroSeal line. These zippers are made for very important uses. They use special materials and building methods to ensure they seal well. With over 20 years of experience, Zizip is a leader in sealing technology.

Key Features and Benefits

AeroSeal zippers have many important features that improve their performance:

Superior Sealing: They keep out dust and help keep temperatures steady in cold storage. This is very important for keeping sensitive products safe.

Rapid Operation: The zippers help reduce temperature changes. This keeps temperature-sensitive products safe, especially in cold storage areas.

Automatic Repair: Their design cuts down on labor costs and downtime by not needing manual repairs.

You can also find AeroSeal zippers in many uses, such as:

Hazardous protective clothing

Diving suits

Thermal clothing

Military equipment

These zippers are used in outdoor activities, military gear, diving, and medical uses. Their flexibility and reliability make them a top choice in many fields.

The zipper design along the door curtain’s edge makes a tight seal against air, dust, and pests. This is very important for keeping cold storage facilities running well. By choosing Zizip’s AeroSeal zippers, you choose quality and performance that fit your industry needs.

Load Management for Cold Storage Doors

Managing loads well is very important for cold storage doors. These doors need to handle different pressures and stresses. This helps keep them strong and controls the temperature inside. You should think about several things when designing and putting in these doors.

Material Selection

Picking the right materials for your cold storage door is very important. The materials you choose affect how long they last and how much weight the airtight zippers can hold. Here are some common materials used:

Thick, insulated PVC curtains that are often layered

Good sealing systems around the zipper track

Heated bottom bars to stop freezing

Materials that resist rust

Great thermal insulation

Tight seals to stop air leaks

Using strong polyester or polypropylene tape is a good idea for industrial uses. These materials can handle shear loads, UV light, moisture, and wear. The best zipper is one made for the specific stress it will face.

Cold storage doors also need to manage different loads, like:

Impact resistance to keep their shape

Good temperature control to keep stored items safe

Fast operation for better efficiency

Adding features like flexible panels and insulation helps meet these load needs.

Installation Techniques

Good installation methods are key for managing loads in cold storage doors. Here are some suggested ways to install:

Gluing: Use neoprene-based glue for metal water/air-tight zippers.

Sewing: Make sure stitches are covered with seam seal tape to keep them waterproof.

RF Welding: Bond similar plastic materials using radio waves, good for PVC and TPU zippers.

Hot Welding: Fuse matching materials with hot air, making sure seams are sealed to stop leaks.

You should also avoid common mistakes during installation that can hurt load management. Here are some problems to look out for:

Common Issues | Solutions |

|---|---|

Heat getting in through poorly sealed doors | Use high-quality insulated doors with good gaskets and automatic closers. |

Moisture around the door frame | Think about air curtains or PVC strip curtains in busy areas to cut down on temperature loss. |

Trouble keeping the inside temperature | Make sure the doors are sealed well and placed correctly to keep the temperature steady. |

By following these tips, you can improve how your cold storage doors work and make sure they meet your needs.

Sealing and Insulation in Cold Storage

Good sealing and insulation are very important for keeping the right temperature in cold storage areas. You must make sure your cold storage places work well and are dependable. Proper sealing stops air from leaking out. This helps avoid temperature changes and keeps sensitive products from spoiling.

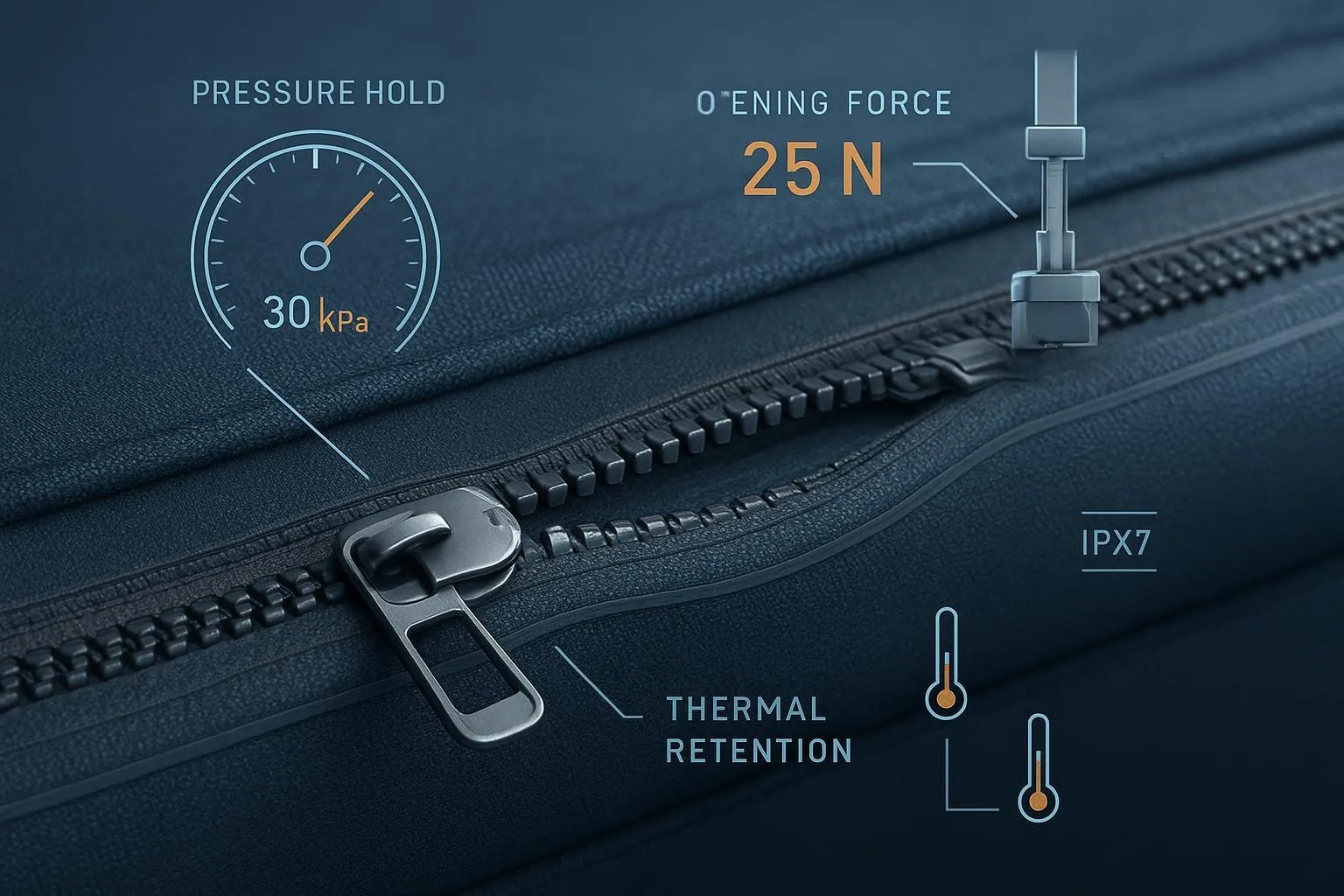

Performance Testing

To make sure your sealing solutions work well, you should do performance testing. This testing checks how well your airtight zippers work in different situations. Here are some important standards and tests to think about:

Testing Standard | Description |

|---|---|

ISO 17109 | Lists requirements and test methods for zippers used in chemical and gas-tight protective clothing. |

ASTM D2061 | Includes tests to check the strength of zippers and their parts, like chain strength and slider pull-off resistance. |

ASTM D2062 | Looks at how zippers work, making sure they operate smoothly in different conditions. |

JIS S3015 | Describes methods for testing the strength and durability of zippers, known worldwide. |

You should also do specific tests to check how well your zippers seal:

Seal Strength: Measures how much force it takes to pull the closed zipper tracks apart.

Repeated Open/Close Cycle Testing: Counts how many times a zipper can open and close before it breaks.

Leak Resistance (Air/Liquid): Checks if the seals can hold air or liquid using pressure tests.

Particle Ingress Testing: Tests if tiny particles can get through the zipper seal.

These tests help make sure your zippers keep their sealing ability, even in tough conditions. Airtight zippers block air and moisture very well. This is key for keeping low temperatures in cold storage. They work better than regular methods like Velcro or snap seals, which can let air leak over time.

Maintenance Practices

To keep sealing and insulation working well for a long time, you should follow regular maintenance steps. Here are some good practices:

Lubricate quarterly: Use silicone lubricant every three months to reduce friction and rust.

Pre-storage cleaning: Always clean before putting gear away for a long time.

Check seals annually: Look for peeling tape or hard areas once a year.

Store properly: Keep zippers half-open to prevent damage to the seals.

Also, think about these tips for taking care of your zippers:

Store open or zipped up halfway: Don’t keep your gear fully zipped for a long time to avoid stress on the teeth and tracks.

Avoid extreme temperatures: Store your gear in cool, dry places to stop damage to the zipper material.

By following these steps, you can improve the sealing and insulation strength of your cold storage solutions. Zizip’s special sealing technology makes sure your zippers work well in tough environments, giving you peace of mind for your operations.

High Speed Doors and Airtight Zippers

High-speed doors are very important in cold storage places. They work well with airtight zippers to make things better and faster. You can see many benefits when you use these two technologies together.

Energy Efficiency

High-speed doors help save energy in cold storage areas. Here are some main benefits:

Evidence Description | Impact on Energy Consumption |

|---|---|

Fast doors keep the time a door is open short, which stops air from escaping. | This helps save energy by keeping the climate steady. |

Better sealing stops air from coming in and gives great thermal insulation. | This leads to big energy savings. |

Quick roll-up doors reduce air leaks, saving energy. | They waste about 70% less energy than regular doors. |

A distribution center in the Midwest cut temperature changes by 60%. | HVAC energy use dropped, saving $18,000 each year. |

Sealed systems need 63% less extra heating, saving $7,100 for each doorway. | This keeps FDA-approved temperatures easily. |

By reducing air exchange, high-speed cold storage doors help keep temperatures steady. This is very important for keeping sensitive products safe.

Operational Flexibility

Using high-speed doors with airtight zippers makes operations more flexible. You can enjoy many benefits:

Zipper-sealed design: This feature gives a tight seal to keep the environment controlled and stop contamination.

Fast opening speeds: High-speed doors let you get in quickly, making operations more efficient.

Smart control systems: These systems change to fit different needs, improving flexibility.

Combining these technologies not only makes things more flexible but also cuts down on maintenance costs. You will see better safety and productivity in your work.

Case Studies and Customer Stories

Lessons Learned

Zizip has worked with big brands like Walmart and Costco. This shows how well its airtight zippers work in different situations. These partnerships show how important good sealing is for keeping products safe. You can learn important lessons from these examples:

Quality Matters: Good zippers keep temperature-sensitive products safe during storage and transport.

Customization is Key: Making zippers fit specific needs improves how well they work.

Regular Maintenance: Having a maintenance plan helps zippers last longer and work better.

These tips can help you choose and take care of airtight zippers for your needs.

Future Innovations

The future of airtight zipper technology looks bright. Zizip is working on new ideas to make them better for industrial and cold storage uses. Here are some cool advancements coming soon:

Seamless welding methods will make zippers stronger and more reliable.

Biodegradable coatings will help the environment without losing performance.

Smart self-healing surfaces will let zippers fix small damages by themselves, making them last longer.

These new ideas will help you stay ahead in the industry, keeping your storage solutions effective and eco-friendly.

By learning from successful examples and welcoming new innovations, you can improve your operations and keep high standards in airtight sealing technology.

To sum up, pay attention to these important design tips for airtight zippers:

Proper sealing: Make sure to close gaps and cracks to reduce air leaks.

Load management: Pick materials that can handle stress and stay strong.

Temperature control: Use insulation well to save energy.

By focusing on these things, you improve energy efficiency and how well things work. Don’t forget, taking care of your zippers is very important. Checking them regularly and caring for them helps them last longer and have fewer problems. This way, you save money and make sure they work well in your cold storage areas.

Follow these tips to keep your operations running smoothly!

FAQ

What are airtight zippers used for?

Airtight zippers create a strong seal in many places. You can see them in cold storage, medical tools, military gear, and suits for dangerous materials. They stop air, gas, and liquid from leaking. This keeps things safe and helps control temperature.

How do I maintain airtight zippers?

To take care of your airtight zippers, use silicone lubricant every three months. Clean them before storing for a long time. Check the seals once a year for any damage. Store zippers half-open to prevent stress on the tracks and teeth.

What materials are used in Zizip’s AeroSeal zippers?

Zizip’s AeroSeal zippers have a strong polyester tape core, a medical-grade TPU coating, and zinc alloy sliders. These materials make them flexible, durable, and create a strong seal against liquids, gases, and tiny particles.

Can I customize the size of the zippers?

Yes, you can change the size of Zizip’s zippers. They come in different lengths and widths, so you can make them fit your needs. You can also choose custom colors and puller designs.

What waterproof ratings do AeroSeal zippers have?

AeroSeal zippers usually have an IPX7 waterproof rating. This means they can be submerged in water. Dual-Track models have an IPX8 rating for even better protection against water getting in.