Testing standards are very important. They help ensure that Airtight-Zippers function effectively in protective clothing. Manufacturers need to be aware of these standards. This knowledge helps avoid issues that can jeopardize safety. For example, a study found that 13.1% of zippers failed in thermal protective suits. This included 12% of zippers breaking when first put on. These statistics highlight the significance of adhering to strict testing regulations. By following these standards, you enhance the reliability of your products. This also contributes to keeping users safe in challenging environments.

Key Takeaways

Knowing testing standards like IPX7 and EN343 is important for manufacturers. These standards make sure airtight zippers work well in protective clothing.

Airtight zippers give important protection against harmful substances. They are very important in personal protective equipment (PPE) and chemical clothing.

Regular testing and keeping records help follow safety standards. This practice makes sure zippers stay reliable and effective.

Picking the right materials is important for durability. Strong materials help zippers resist damage from chemicals and tough environments.

Using high-quality zippers like Zizip‘s can improve safety and performance. These zippers meet strict standards, ensuring protection in dangerous situations.

Overview of Airtight Zippers

Definition and Function

Airtight zippers are special closures. They stop liquids and gases from getting in. These zippers are very important in protective clothing. They make a strong seal to keep harmful things out. There are different types of airtight zippers used in making protective clothing:

Woven nylon airtight zippers: They are flexible and strong, great for clothing.

Resin airtight zippers (AQUASEAL): They resist chemicals well, good for tough places.

Metal airtight zippers (YKK’s PROSEAL): They are very durable and seal tightly under pressure.

These zippers use smart technologies to seal effectively.

Importance in Protective Clothing

Airtight zippers are key for personal protective equipment (PPE) and chemical clothing. They give important protection in dangerous places. Here are some benefits of using airtight zippers in protective clothing:

Hazardous Material Suits: Airtight zippers stop dangerous chemicals and germs, keeping the wearer safe.

Dry Suits for Emergency and Rescue Operations: They keep rescuers dry and safe from harmful things.

Protective Gear for Industrial and Chemical Environments: Airtight zippers lower health risks by blocking contact with dangerous substances.

Firefighting Equipment and Gear: They keep outside dangers out and hold important insulating air layers for safety.

Medical and Biosecure Isolation Gear: Airtight zippers help stop germs from spreading in hospitals.

These zippers are made with materials that resist rust and damage from chemicals. This strength helps them work well even in tough conditions.

Key Isolation Property | Function |

|---|---|

Hermetic Sealing | Creates a complete, airtight, and watertight barrier against fluids and airborne pathogens. |

Tri-Seal Technology | Uses a triple interlocking structure of the zipper teeth that makes three sealing points when closed, forming a strong barrier against gas and liquid. |

HF Weldable Tapes | The zipper tape is made to support High-Frequency Welding to the suit fabric, making a strong, seamless bond that cuts down the risk of leaks. |

By knowing what airtight zippers are and how they work, you can see why they are important for safety and protection in many uses.

Testing Standards for Airtight Zippers

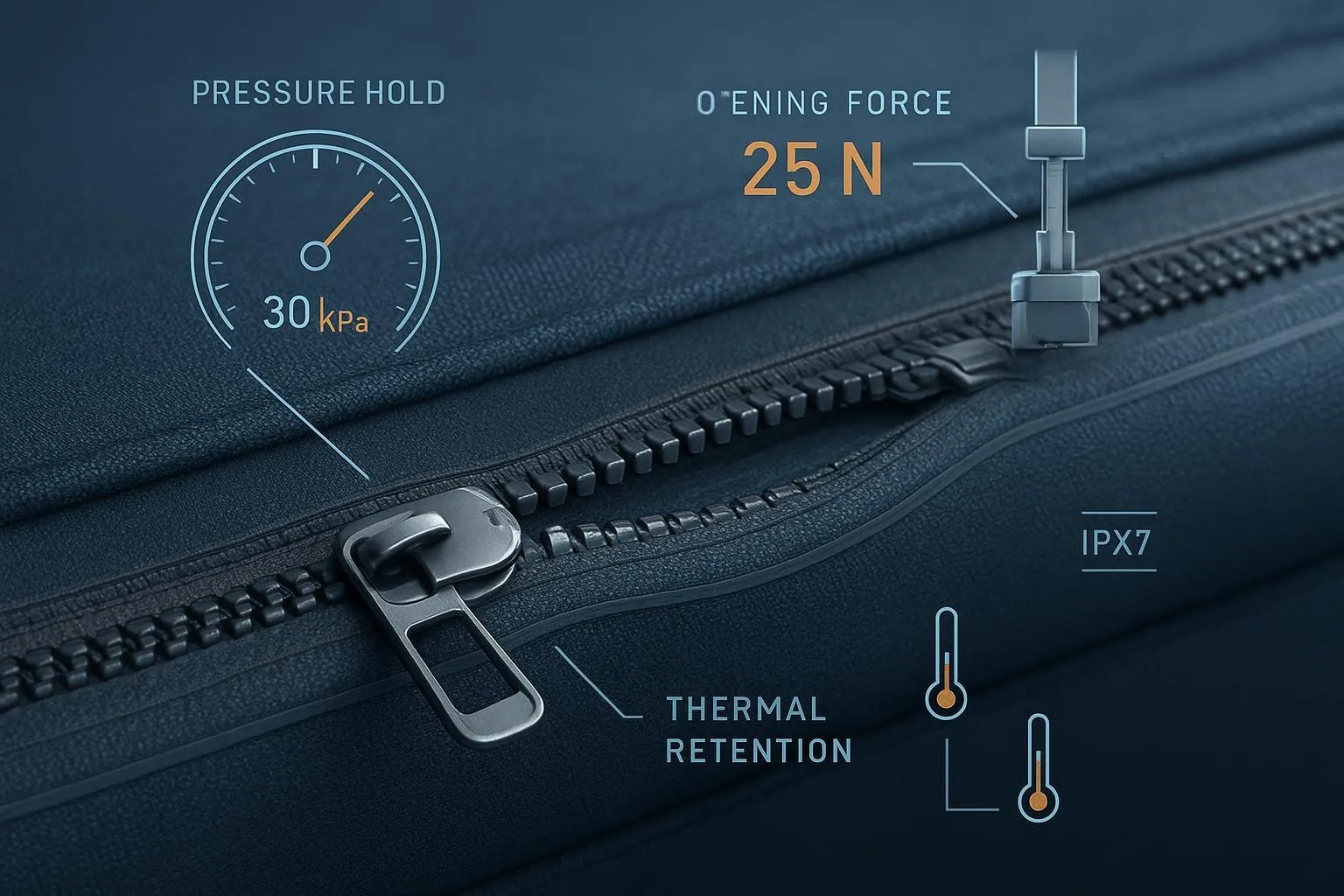

IPX7 Standard

The IPX7 standard is very important. It makes sure that airtight zippers work well in different places. This standard checks how waterproof the zippers are. It confirms they can handle being underwater. Here are the main rules of the IPX7 standard for airtight zippers in protective clothing:

Inspection Item | Test Result | Compliance Threshold |

|---|---|---|

Waterproof Rating | IPX7 (SGS) | GB/T 4208-2017 IPX7 |

You can expect these things from zippers that pass the IPX7 standard:

Complete Protection: They stop liquids and gases from getting in, even when fully underwater.

Exceptional Airtightness: They are made to avoid leaks when pressure changes.

Superior Strength: They can handle a strength of 1205 N, which is more than the 900N limit.

To check for water getting in, the test involves putting the zipper bag underwater at 1 meter deep. The zipper passes if no harmful water gets in after 30 minutes.

Test Procedure | Pass Criteria |

|---|---|

Submerge bag at 1 m | No harmful water ingress after 30 minutes |

This careful testing makes sure that the zippers in protective clothing can handle tough situations. They provide safety and good performance.

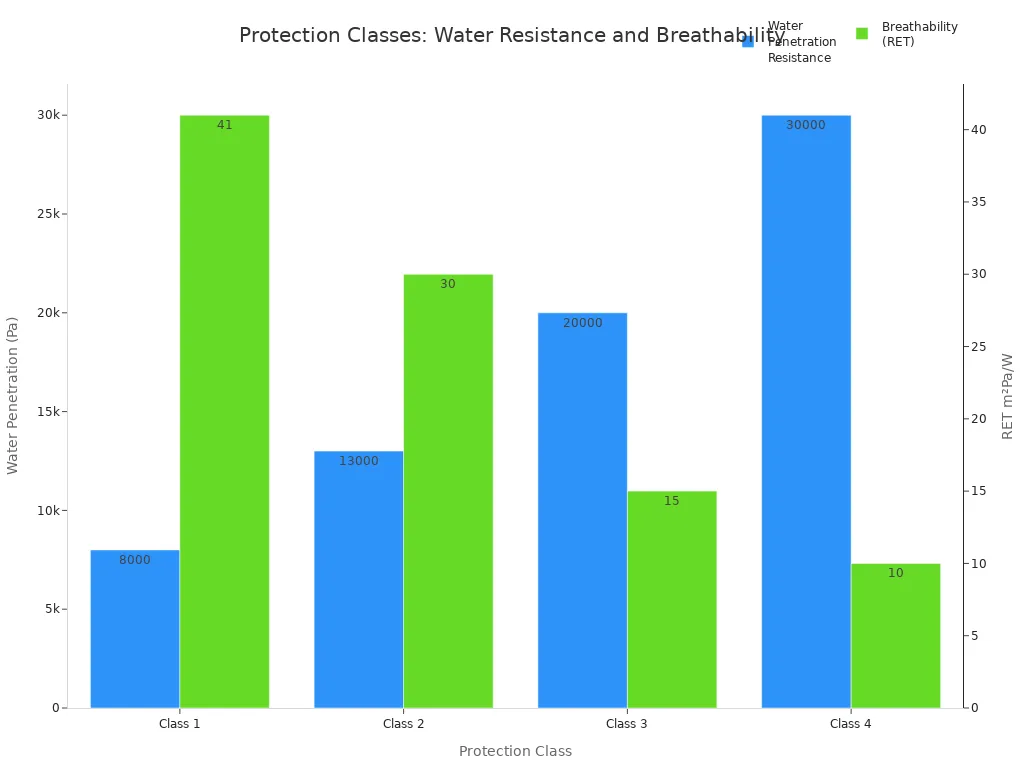

EN343 Standard

The EN343 standard looks at how clothing performs in rain and wet weather. It checks two main things: how well it stops water and how breathable it is. This standard is key to making sure protective clothing stays useful and comfy in bad weather. Here’s a summary of the EN343 standard:

Category | Description |

|---|---|

Water Penetration Resistance | Tests how well it protects against rain, fog, and humidity. |

Breathability | Measures how breathable it is when stopping water. |

Ratings | 1. Minimum rain protection 2. Intermediate rain protection 3. Highest rain protection |

By following the EN343 standard, manufacturers can make sure their airtight zippers help protective clothing work well. This standard keeps comfort while giving the needed protection against dangerous materials and weather.

Compliance for Protective Clothing

Steps for Manufacturers

To make sure your airtight zippers meet testing standards for protective clothing, follow these important steps:

Understand the Standards: Learn about standards like IPX7 and EN343. Knowing what they require helps you create zippers that fit these rules.

Select Appropriate Materials: Pick materials that resist damage from chemicals and the environment. This choice is key for keeping zippers strong and working well.

Conduct Rigorous Testing: Set up regular tests to check how well your zippers perform. This includes testing for waterproofing, airtightness, and chemical resistance.

Document Compliance: Keep detailed records of all tests and results. Good documentation is important for showing compliance during audits or inspections.

Continuous Improvement: Stay informed about new zipper technology and materials. Regularly check and improve your processes to boost product performance and compliance.

By following these steps, you can make sure your airtight zippers give the needed protection in many uses, like personal protective equipment (PPE) and chemical protective clothing.

Challenges in Compliance

Manufacturers often face challenges when trying to meet testing standards. Here are some common problems:

Material Degradation: Harsh chemicals can damage materials. This can hurt the zipper’s performance and how long it lasts.

Rigorous Testing Requirements: Extensive testing can use up resources. You need to ensure zippers stay airtight under pressure.

Selecting Durable Materials: Choosing the right materials and coatings is key for durability and compliance. Making a corrosion-resistant zipper means treating parts like the slider and teeth to handle tough conditions.

Marine covers exposed to seawater and UV absorb salts that corrode zippers from within. Personal protective equipment (PPE) suits rely on zippers that must remain airtight when splashed with acids or solvents.

To fix testing failures, manufacturers usually do regular tests. This proactive approach helps spot problems early, preventing safety issues and extending the life of the suits. By understanding these challenges, you can be better prepared to meet compliance needs and improve the reliability of your products.

Zizip’s Airtight Zippers

AeroSeal Dual-Track Features

Zizip’s AeroSeal Dual-Track zippers are special because of their smart design and great performance. These zippers give strong protection in important situations. Here are some main features:

Feature | Description |

|---|---|

IPX8+ Redundant Sealing | Offers a backup seal to stop leaks under high pressure. |

Extreme Pressure Resistance | Keeps a tight seal at pressures up to 120kPa, which is better than the 100kPa standard. |

Exceptional Tensile Strength | Has a strength of 1673 N, which is over 67% stronger than regular zippers, made for tough use. |

Mission-Critical Durability | Can handle 1500 cycles under load, making it reliable for safety equipment. |

These features make Zizip’s airtight zippers great for tough environments. You can count on them to protect you when working with dangerous materials and chemicals.

Advantages of Zizip Zippers

Using Zizip’s airtight zippers has many benefits for your protective clothing. Here are some advantages:

High Performance: Zizip zippers have a strength of 970N, so they can handle tough conditions.

Durability: They last through over 2,000 cycles, perfect for regular use in personal protective equipment (PPE).

Environmental Resilience: Zippers show no damage after being in extreme temperatures from -30°C to 100°C. This makes sure they work well in different weather.

Enhanced Safety: The strong build and sealing technology give reliable protection against chemicals and harmful substances.

By using Zizip’s zippers in your protective clothing, you improve safety and performance. These zippers are made to meet strict testing standards, ensuring they give the needed protection in dangerous situations.

Chemical Protective Clothing Standards

Importance of Airtight Zippers

Airtight zippers are very important in chemical protective clothing. They stop harmful substances from getting inside the suit. This gives essential protection for the person wearing it. In places where there are dangerous materials, these zippers create a strong barrier. You can trust that good airtight zippers will keep your protective gear safe.

Here are some key standards that mention airtight zipper needs:

Type | Description |

|---|---|

Type 1 | Airtight Leakage Test |

Type 2 | Inward Leakage Test |

Type 3 | Jet Test |

Type 4 | Spray Test |

Type 5 | Particle Inward Leakage Test |

Type 6 | Low Level Spray Test |

These standards make sure your protective clothing meets the right chemical protection requirements. They help you choose the right gear for different uses, keeping you safe in risky environments.

Testing for Chemical Resistance

Testing for chemical resistance is very important. It checks how well airtight zippers work in protective clothing. You should know about several tests that see how zippers resist chemicals. Here’s a summary of the main tests:

Test Type | Description | Classification |

|---|---|---|

Penetration Resistance | Tests how well the fabric stops liquid chemicals | Classified from 1 to 6 |

Permeation Resistance | Tests the fabric and seams against gas chemicals | Classified from 1 to 6 |

Cumulative Breakthrough Mass | Measures the time until a certain amount of chemical is reached | Classified from 1 to 6 |

Normalized Breakthrough | Measures how fast chemicals get through over time | Classified from 1 to 6 |

These tests help you check how strong and effective your zippers are against different chemicals. By making sure your zippers pass these tests, you can ensure that your protective clothing will give the needed safety and reliability in dangerous situations.

Following testing standards like IPX7 and EN343 is very important. They help make sure protective clothing works well and is reliable. These standards guide you in making zippers that can handle tough conditions and keep users safe.

Look at this table that shows why these standards matter:

Class | Water Penetration Resistance (Pa) | Breathability (RET m²Pa/W) |

|---|---|---|

1 | Minimum 8,000 | > 40 |

2 | Minimum 13,000 | 20 – 40 |

3 | Minimum 20,000 | 10 – 20 |

4 | Minimum 30,000 | ≤ 10 |

By focusing on meeting these standards, you make your products safer and stronger. This effort not only protects users but also improves your brand’s image in the market.

Use these standards to make sure your protective clothing meets the best safety needs.

FAQ

What is the IPX7 rating?

The IPX7 rating shows that a product can be underwater up to 1 meter for 30 minutes without leaking. This rating makes sure protective clothing stays waterproof.

How do I choose the right airtight zipper?

Pick an airtight zipper based on what you need. Think about things like waterproof rating, strength, and the environment. Zizip’s AeroSeal zippers have different options for various uses.

Can Zizip zippers be customized?

Yes, you can customize Zizip zippers in length, width, and color. This lets you adjust the zippers to match your product needs and design choices.

How do I maintain airtight zippers?

To keep airtight zippers in good shape, clean them often with mild soap and water. Stay away from strong chemicals that can harm the materials. Store zippers in a cool, dry spot to avoid damage.

What industries use airtight zippers?

Airtight zippers are used in many industries like military, medical, aerospace, and outdoor gear. They give important protection in places where safety and reliability are very important.