Zippers are very important for many products. If a zipper fails, the whole item can be useless. This can frustrate users a lot. Recent studies show that zipper problems cause 78% of failures in ice fishing suits. This number shows why zippers need to be strong and durable. To make sure zippers work well, standards like ASTM D2061 set rules for quality and reliability. Knowing these standards is important for manufacturers who want to make strong and reliable products.

Key Takeaways

Zipper durability is very important for how well products work, especially outdoor gear. Strong zippers stop product failures and make users happier.

Standards like ASTM D2061 and BS 3084 help makers ensure zippers are good quality and reliable. Following these standards can lower warranty claims.

Standard tests, like tensile and fatigue testing, clearly show zipper strength and durability. These tests find weaknesses before products reach buyers.

Choosing the right standard depends on the market. ASTM D2061 is best for North America, while BS 3084 is good for the UK and Europe.

Makers can improve zipper quality by using durability standards in their design and testing. This creates better products and happier customers.

Zipper Durability: Why Standards Matter

Role of Durability in Product Performance

Zipper durability is very important for how well products work. This is especially true for outdoor gear. Strong zippers are needed for tents, backpacks, and special clothes. These zippers must handle stress, moisture, and bad weather. For instance, metal zippers are very strong, while molded plastic zippers resist rust. This strength helps keep products safe in tough conditions.

More people are enjoying outdoor activities like hiking and camping. This has made durable, water-resistant gear more popular. Waterproof zippers stop water from getting in. This improves how outdoor clothes and gear work. When zippers break, the whole product can fail, which makes customers unhappy. So, manufacturers need to focus on zipper durability to create long-lasting and reliable products.

Standardized Testing for Quality Assurance

Standardized testing gives a clear way to check quality across different makers. It makes sure zippers meet certain performance standards. This helps keep product quality the same. Different testing methods help with this:

Testing Method | Purpose |

|---|---|

Tensile Testing | Checks the most force a zipper can take before breaking. |

Fatigue & Corrosion Testing | Mimics years of use with many open/close cycles. |

Thermal & Fire Testing | Tests strength under extreme heat, cold, or fire. |

Abrasion Resistance | Looks at how well zippers resist wear from rubbing. |

By following standards like ASTM D2061, manufacturers can lower failure rates and make products last longer. This means fewer warranty claims and better relationships with suppliers. In the end, standardized testing helps build trust in production, making sure customers get high-quality products.

ASTM D2061: American Zipper Performance Standard

Overview of ASTM D2061: Scope and Objectives

ASTM D2061 is an important standard for zipper performance. It sets clear goals to make sure zippers are strong and reliable. The table below shows the main goals of ASTM D2061:

Objective | Description |

|---|---|

Mechanical Strength | Make sure zippers can handle common forces during use (pulling, twisting, closing/opening, etc.) |

Product Comparison | Compare different zipper products based on strength performance. |

Weakness Detection | Find design or material weaknesses that could cause failure. |

These goals help manufacturers create zippers that work well in different situations.

Key Tests and Methodologies in ASTM D2061

ASTM D2061 has several important tests to check zipper durability. Each test looks at different parts of zipper performance. The table below lists these tests and how they work:

Test Type | Description |

|---|---|

Load-to-Failure | Measures the highest load a zipper can take before it fails. |

Slider Endurance | Checks how long the zipper slider lasts with repeated use. |

Chain Strength | Tests the strength of the zipper chain to see if it is good for different uses. |

Tensile Strength | Finds out how much pulling force a closed zipper can take before it breaks. |

Methodology for Tensile | The zipper chain is held at both ends and pulled apart until it fails, measuring the peak load at that point. |

These tests give a full picture of zipper performance, helping manufacturers make reliable products.

Interpreting ASTM D2061 Results and Compliance

Manufacturers check results from ASTM D2061 tests against set rules to see if they follow the standards. Each test has specific limits that zippers must meet. For example, a zipper must hold a minimum load in the Load-to-Failure test to be considered okay. By following these standards, manufacturers can make sure their zippers are strong and dependable, which improves product quality and keeps customers happy.

BS 3084: British Standard for Slide Fasteners

Overview of BS 3084: Scope and Objectives

BS 3084 is an important standard for checking how zippers work. This standard helps make sure zippers are strong and reliable. The main goals of BS 3084 are:

Making sure zippers are strong during normal use.

Helping compare different zipper products based on how well they perform.

Finding any weak spots in design or materials that might cause problems.

These goals help manufacturers make zippers that work well in many situations.

Key Tests and Methodologies in BS 3084

BS 3084 lists several important tests to check zipper strength. Each test looks at different parts of how zippers work. Here are the main tests mentioned in the standard:

Breaking strength across the chain

Single element pull-off strength

Single element pull slippage

Single side top holding strength

Holding strength of the slider lock

Top stop holding strength

Bottom stop holding strength

Box strength

Holding strength of box and pin

Slider pull twist strength

Resistance to pull-off of slider pull

These tests give a complete look at how zippers work, helping manufacturers make dependable products.

Interpreting BS 3084 Results and Compliance

Manufacturers check test results against set standards to see if they follow BS 3084. The table below shows key test types and what they mean:

Test Type | Description |

|---|---|

Puller attachment strength | Tests how strong the puller attachment is. |

Closed end strength | Checks the strength of closed-end zippers. |

Top stop strength | Looks at how strong the top stop is. |

Open end fastener box strength | Tests how strong open-end fasteners are. |

Single stringer slider retention | Checks how well single stringer sliders stay in place. |

Reciprocation test | Tests how durable zippers are through repeated use. |

Lateral strength of open end attachment | Looks at the side strength of open-end attachments. |

Slider locking device strength | Tests how strong the slider locking device is. |

By following these standards, manufacturers can make sure their zippers are strong enough, improving product quality and keeping customers happy.

ASTM D2061 vs. BS 3084: Similarities and Differences

Comparing Test Parameters and Requirements

Both ASTM D2061 and BS 3084 are important standards for zipper performance. They have some things in common but also some differences.

Common Goals: Both standards want to make sure zippers can handle everyday use. They focus on strength, durability, and reliability.

Testing Methods: Each standard uses strict testing methods to check how zippers perform. For example, both have tensile strength tests to see how much force a zipper can take before it breaks.

But the details of the tests are different:

Test Aspect | ASTM D2061 | BS 3084 |

|---|---|---|

Load-to-Failure | Measures the highest load before failure | Not clearly defined |

Slider Endurance | Checks how long the slider lasts | Includes slider pull twist strength |

Chain Strength | Looks at the overall strength of the chain | Focuses on single element pull-off strength |

These differences show how each standard fits its tests to what the industry needs.

When to Apply Each Standard

Manufacturers should pick between ASTM D2061 and BS 3084 based on their target markets and product needs.

ASTM D2061: This standard is best for manufacturers in the American market. It matches what consumers want, especially for durable outdoor gear and clothing.

BS 3084: This standard works better for manufacturers in the UK and Europe. It meets local preferences and rules, making it important for products sold there.

Knowing when to use each standard helps manufacturers meet customer needs and follow local laws.

Regional Market Impact on Standard Selection

Choosing between ASTM D2061 and BS 3084 often depends on what the local market wants.

North America: Here, consumers want strong zippers that can handle tough conditions. So, ASTM D2061’s focus on strength and durability is popular with both manufacturers and consumers.

Europe: In Europe, markets might care more about environmental issues and sustainability. BS 3084 covers these topics, making it a better choice for manufacturers who want to meet European standards.

By understanding these local differences, manufacturers can better sell their products worldwide.

Practical Application: Implementing Durability Standards

Integrating Standards into Product Design

Manufacturers are very important for making sure zippers meet durability standards like ASTM D2061 and BS 3084. They start by picking strong materials that can handle different weather conditions. In the design phase, they use strict testing methods to check that zippers work well under pressure.

During product development, manufacturers usually follow these steps:

Material Selection: Picking strong materials like high-density polyester and TPU coatings to improve durability.

Prototyping: Making initial samples to test how well the zipper works.

Testing: Doing standardized tests to check strength, resistance to rust, and how long the zipper lasts.

By including these standards in their design processes, manufacturers can make zippers that not only meet but also go beyond what customers expect.

Quality Control for Zipper Manufacturers

Quality control is very important for keeping up with zipper durability standards. Manufacturers use different quality assurance methods to make sure their products meet the needed specifications. Some key methods include:

Zipper Fatigue Testing: This method mimics real use by opening and closing zippers many times to find weak spots and check long-term performance.

Strength Testing: Makes sure zippers can handle the forces they will face in real life.

Performance Verification: Done in labs to check strength, rust resistance, and how long the zipper lasts.

Also, manufacturers follow ASTM-certified testing methods. They create traceable data to meet OEM, NFPA, and MIL-SPEC documentation needs. These practices help ensure that zippers stay reliable and durable throughout their use.

ZIZIP’s Commitment to Exceeding Standards

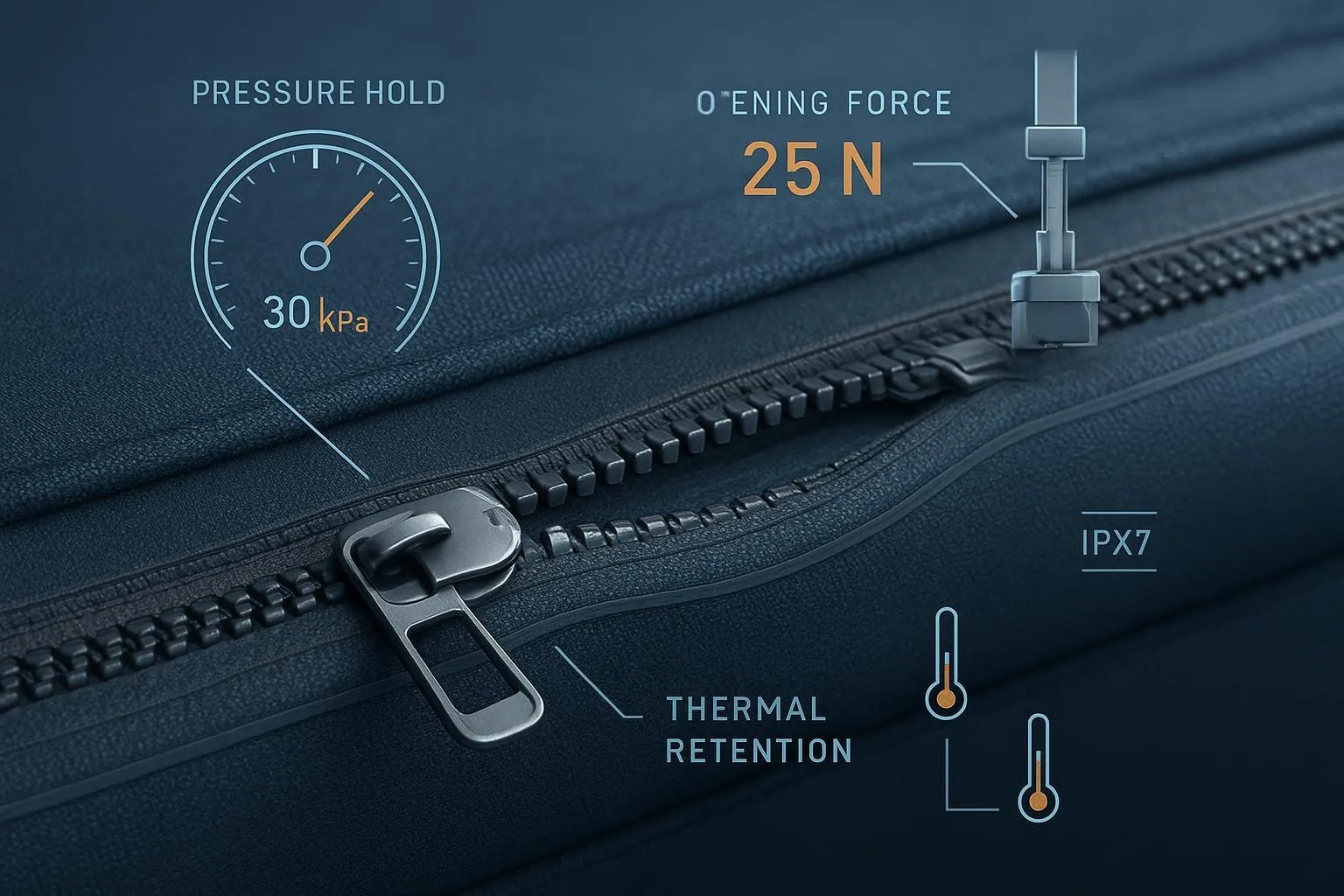

ZIZIP shows a strong commitment to going beyond zipper durability standards. The company includes ASTM D2061 and BS 3084 in every part of its product development process. ZIZIP’s AeroSeal and AquaSeal zippers have impressive IPX ratings from IPX5 to IPX8. This certification shows they can effectively resist water getting in.

Feature | Description |

|---|---|

IPX Rating | Certified to achieve IPX5 waterproof rating, resisting heavy rain and pressurized water spray. |

Material | High-density polyester fabric coated in thermoplastic polyurethane (TPU). |

Sealing Technology | Forms a continuous compressible sealing layer through mutual compression of TPU coatings. |

Testing Protocols | Passes water jets up to 100 L/min at 30 kPa, 48-hour salt spray corrosion test, and extreme temperature tests (-30°C to 100°C). |

ZIZIP’s zippers also show great durability, achieving over 2000 cycles of use, which is twice the requirement set by ASTM D2061. This shows their excellent performance in tough conditions.

ZIZIP has ISO 9001:2015 certification, proving its quality control processes and zipper durability claims. The company’s strict quality assurance methods include third-party checks through SGS test reports. These reports confirm ZIZIP’s commitment to keeping high standards in strength, durability, and environmental resistance.

Moreover, ZIZIP’s special engineering and over 30 patents help it exceed global standards. The company offers OEM/ODM services, allowing clients to customize zippers to meet specific durability needs. This flexibility ensures that ZIZIP can serve many industries, from outdoor gear to aerospace applications.

Following zipper durability standards like ASTM D2061 and BS 3084 is very important for manufacturers. These standards help make sure products are reliable, safe for consumers, and good for the brand’s image. They ensure zippers work well, which stops problems that could upset customers. High-quality zippers make clothes last longer, meeting what consumers expect. If a zipper breaks, it can hurt a brand’s image and make customers lose trust.

New trends in zipper durability standards include:

Trend | Description | Impact on Product Development |

|---|---|---|

Sustainability | Focus on using eco-friendly materials and making products in a green way. | Encourages manufacturers to use responsible practices when making zippers. |

Lightweight Design | Need for zippers that are strong but also lighter. | Promotes making zippers that improve comfort and usability in different products. |

Customization | Growing demand for zippers that fit specific consumer needs. | Drives new ideas in zipper design to match client needs and brand styles. |

Quiet, Smooth Functionality | Zippers made to work quietly, especially in quiet products. | Improves user experience in items like car interiors and outdoor gear. |

Fashion-Forward Design | Zippers that are stylish and functional at the same time. | Encourages manufacturers to create zippers that look good and attract consumers. |

For companies like ZIZIP, following these strict testing rules shows a commitment to quality and builds trust with customers. As the market changes, these standards will stay important, helping manufacturers create innovative and reliable zipper solutions.

FAQ

What is ASTM D2061?

ASTM D2061 is a rule that explains how zippers should work. It makes sure zippers can handle different forces when used, which helps them last longer and work better.

What does BS 3084 cover?

BS 3084 is an American standard for zippers. It examines how strong zippers are and how well they function. This ensures zippers meet certain standards for durability and how they function.

Why are zipper durability standards important?

Zipper durability standards are very important for making reliable products. They help manufacturers create high-quality zippers that make users happy and lower the chances of product failures.

How do manufacturers test zippers for durability?

Manufacturers do standard tests like tensile strength and fatigue testing. These tests check how well zippers hold up under pressure and after being used many times.

Can ZIZIP zippers exceed these standards?

Yes, ZIZIP zippers often go beyond ASTM D2061 and BS 3084 standards. They are tested carefully and use advanced materials to ensure they are very durable and perform well.