Airtight zippers are very important for keeping pressure safe in high ΔP areas. These situations often happen in places like chemical factories. If zippers break, people can be exposed to dangerous materials. For example, a broken zipper in firefighter gear or military uniforms can cause serious exposure to fire or chemicals.

In places with toxic chemicals or biohazards, airtight zippers are the first protection. They stop harmful substances from getting into protective suits. The main question is: how can you keep pressure safe in these changing and high-pressure situations?

Key Takeaways

Airtight zippers are very important for safety in high-pressure places. They stop harmful substances from getting in.

ZIZIP‘s design mixes flexibility and strength. This makes a strong seal while still allowing movement.

Picking the right materials, like strong polyester and special coatings, makes zippers last longer and work better.

Knowing common weak spots, like zipper teeth and seams, helps make airtight zippers more reliable.

ZIZIP’s AeroSeal zipper has a special sealing system. It gives extra protection against leaks in tough conditions.

Benchmark analysis: Design wisdom of professional compression clothing

Design philosophy of compression suit: System engineering with absolute pressure integrity as the core.

When you design compression suits, you need to keep pressure safe. This helps the suit fit tightly on the body. A good fit stops air from leaking and keeps the right pressure. You can do this by carefully planning how the body moves and what the suit is made of.

ZIZIP Interpretation Key Features: Rigid flexible balance, sealing of movable joints, multi-layer safety redundancy.

ZIZIP uses similar ideas for its airtight zippers. The zippers mix stiffness and flexibility. This lets them work smoothly while keeping a strong seal. They also have designs that close movable joints well. This stops leaks at important spots, keeping you safe in high-pressure areas. Multi-layer safety redundancy gives extra protection. If one layer fails, others stay strong, keeping the zipper safe.

Inspiration from Materials Science: Selection and Application of High Strength and Low Permeability Materials, and ZIZIP’s Understanding of Materials for This.

Choosing the right materials is very important for compression suits and airtight zippers. Here are some common materials used:

Metal Zippers: Made from brass, nickel, or aluminum, these zippers are very strong. They can handle a lot of stress but might rust without coatings.

Plastic Zippers: Made from molded acetal or nylon, these zippers are flexible and resist rust. They are light and can be very water-resistant when used with sealed tape.

Material Selection: Picking between metal and plastic zippers depends on what you need. Each material has special strengths that affect how well they work over time.

By knowing these design ideas and material facts, you can see how ZIZIP’s airtight zippers do well in high-pressure situations.

Core challenges and failure modes in high Δ P scenarios

In depth understanding of the impact of Δ P: the physical effects of pressure difference on structure, sealing interface, and materials.

High ΔP means there is a big difference in pressure. This difference can really change how airtight zippers work. You need to know how this pressure difference affects the zipper’s parts and seals. Here are some important effects:

High ΔP raises contact pressure and friction at seals.

It can cause the lubrication film to thin or break. This film is important for smooth use.

There is a greater chance of media getting in through tiny gaps at the seals. This can speed up wear and cause seal failure.

These issues can weaken the zipper, leading to problems in important uses. You should think about these effects when designing or choosing airtight zippers for high-pressure situations.

Analysis of typical failure points: Failure mechanisms of weak links such as zippers, seams, valves, etc. under high Δ P.

In high-pressure situations, some parts are more likely to fail. Zippers, seams, and valves are often weak points in the system. Knowing how these parts fail helps you reduce risks. Here are some common weak points:

Zipper Teeth: The teeth can bend under high pressure, causing misalignment. This misalignment can create gaps that let leaks happen.

Sealing Interface: The area where the zipper meets the fabric can wear down over time. High ΔP can make this wear worse, leading to seal failure.

Seams: Seams are often stressed in high-pressure areas. If they are not strong enough, they can rip or come apart, ruining the whole suit or gear.

Valves: Valves that work with zippers can fail if they can’t handle the pressure. This can cause quick decompression or exposure to dangerous materials.

By spotting these weak points, you can take steps to make airtight zippers more reliable in high ΔP situations. Choosing strong materials and using good design can greatly lower the chance of failure.

Insight from ZIZIP: Combining ideas from compression clothing with airtight zippers

Learning from compression suits to improve zippers: how ZIZIP uses design ideas for strong sealing.

ZIZIP learns important lessons from compression suits. These suits focus on keeping pressure safe and being comfortable. This is very important in high-pressure places. By using these ideas, ZIZIP makes its airtight zippers work better. Here are some main points:

Better Fabric Technology: ZIZIP uses a special mix of materials. This mix helps with breathability and stretch while keeping the right pressure.

Adjustable Tightness: You can change how tight the zippers are. This feature helps with different needs, making it more comfortable and useful.

Improved Zipper Design: The new zipper design works more smoothly. This helps avoid snags and makes the zipper last longer.

Stronger Stitching: Stronger stitching stops tearing. This helps the zipper last and work well every day.

These upgrades show how ZIZIP combines compression suit technology into its zippers, leading to strong sealing.

Core Technology Unveiled: ZIZIP AeroSeal ™ zipper

Design idea: Inspired by “full path sealing” and “pressure adaptive” concepts from compression clothing.

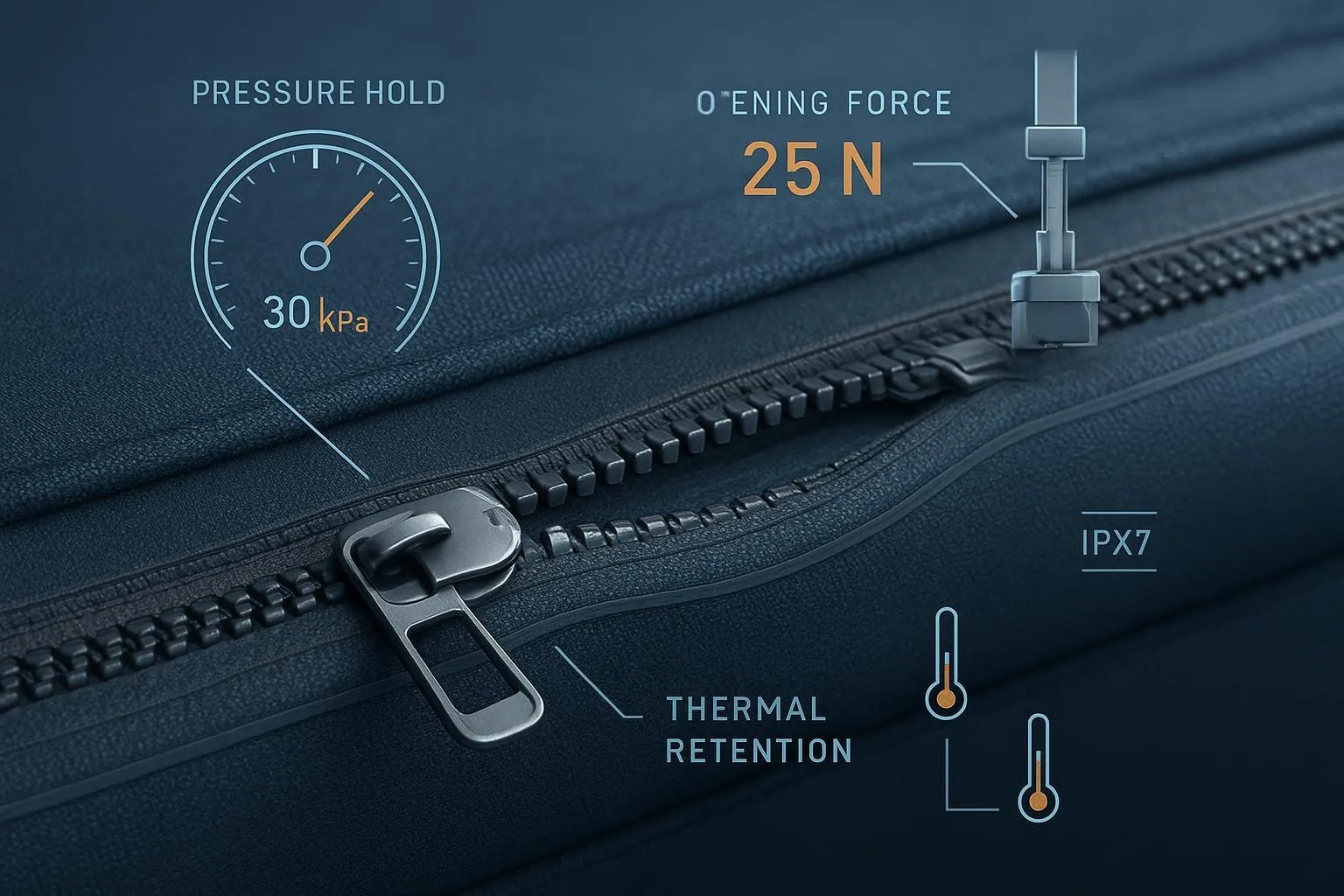

The ZIZIP AeroSeal zipper shows the idea of “full path sealing.” This means it makes a complete barrier against outside elements. The zipper adjusts to pressure changes, making sure it fits well. This design lowers the chance of leaks, even in changing situations. You can trust that the zipper will stay strong under different conditions.

Structural innovation: explaining how it solves problems of distortion, separation, and leaks caused by high Δ P.

ZIZIP’s structural changes solve common problems in high ΔP situations. The AeroSeal zipper has:

Strong Design: This design stops distortion and separation under pressure. It keeps a tight seal, so no gaps appear.

Smart Interlocking Mechanism: The interlocking teeth make it stronger. This mechanism lowers the chance of leaks, even in tough conditions.

Multi-layered Sealing System: This system adds extra safety. If one layer fails, others still work, keeping you protected.

These changes make the AeroSeal zipper a trustworthy choice for high-pressure uses.

Material Fusion: Using knowledge from studying materials for compression clothing to improve strength and wear resistance.

ZIZIP uses advanced materials to boost its zippers’ performance. The AeroSeal zipper includes:

Strong Polyester Tape Core: This core gives strength and flexibility, letting the zipper handle stress without losing its seal.

Medical-grade TPU Coating: This coating resists wear and tear well. It keeps the zipper working even in tough environments.

Zinc Alloy Slider: The slider makes it easy to use. It ensures a secure closure while being simple to operate.

By using these materials, ZIZIP improves the strength and wear resistance of its airtight zippers, making them great for extreme conditions.

ZIZIP changes how sealing works in high-pressure places. You gain from our deep knowledge and new designs. Our AeroSeal™ Zipper is a proven choice for tough conditions. By using ideas from compression suits, we make sure our airtight zippers give great protection. You can count on ZIZIP for sealing solutions that handle your hardest tasks.

FAQ

What are airtight zippers?

Airtight zippers make a complete seal against liquids, gases, and tiny particles. They are very important for protective gear in high-pressure places. They help keep you safe and maintain the gear’s quality.

How do ZIZIP’s AeroSeal zippers perform under pressure?

ZIZIP’s AeroSeal zippers stay sealed at pressures up to 120kPa. They have a multi-layered sealing system that gives extra protection against leaks.

Can I customize ZIZIP zippers for my specific needs?

Yes, you can change ZIZIP zippers in size, color, and material. This lets you meet your special needs for different uses.

What industries benefit from using ZIZIP airtight zippers?

Industries like military, medical, and aerospace gain a lot from ZIZIP airtight zippers. These zippers offer reliable sealing solutions in tough conditions.

How do I ensure the longevity of my ZIZIP zippers?

To make your zippers last longer, check them often for wear and tear. Clean them gently and keep them in a cool, dry place when not in use.